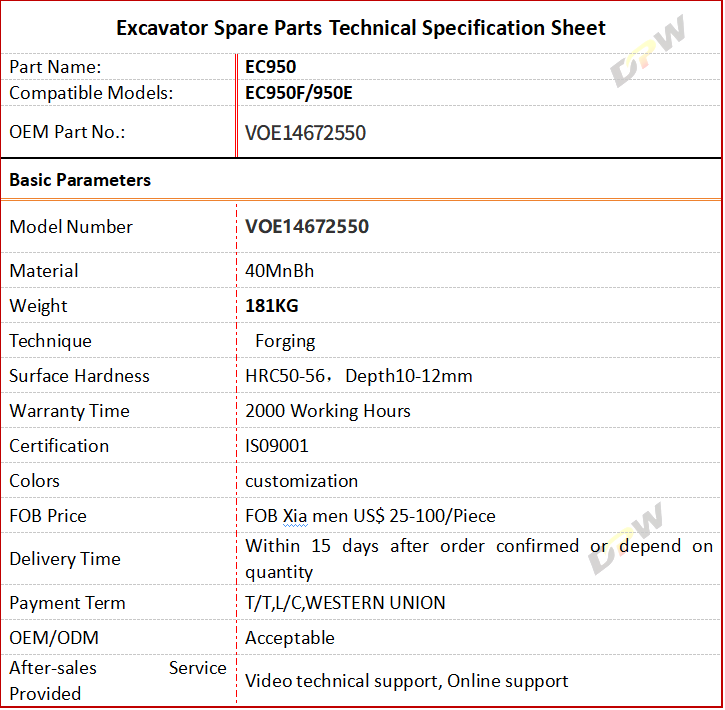

Vollvo-EC950(VOE14672550) track roller/bottom roller/China track rollers factories/china track roller supply/

Product Specifications

Volvo EC950(VOE14672550) Track Rollers – Heavy-Duty Undercarriage Rollers for 90-Ton Excavators

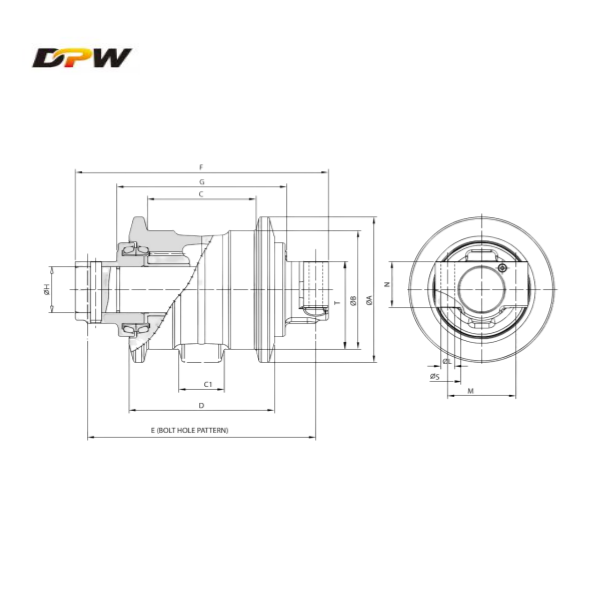

Volvo EC950 track rollers are engineered for 90-100 ton class excavators, designed to withstand extreme loads in mining, quarrying, and large-scale earthmoving operations. These high-performance rollers ensure smooth track movement, reduced vibration, and extended undercarriage life in the most demanding conditions.

Volvo EC950(VOE14672550 Bottom roller) Track Rollers – Heavy-Duty Undercarriage Rollers for 90-Ton Excavators

Volvo EC950 bottom rollers are critical load-bearing components designed specifically for 90-100 ton class excavators, providing reliable support in extreme mining, quarrying, and heavy construction applications. These rollers ensure smooth track movement while withstanding massive dynamic loads and abrasive wear.

✔ Forged Steel Construction – Superior strength and fatigue resistance vs. cast rollers

✔ Mining-Optimized Design – 40mm thick flanges prevent track derailment

✔ Sealed & Lubricated Bearings – Triple-lip seals with grease purge system

✔ OEM-Equivalent Quality – Direct replacement for Volvo EC950/EC950F undercarriages

✔ Hardened Wear Surface – Induction-hardened to HRC 58-62 (6-8mm depth)

Technical Specifications

Parameter Specification Dynamic Load Capacity 48,000 kg Bearing Type 85mm tapered roller bearings (Timken/Koyo equivalent) Flange Design Double-flange with wear indicators Seal System Labyrinth + pressure-compensated grease channels Weight 185 kg per roller

| Parameter | Specification |

|---|---|

| Dynamic Load Capacity | 48,000 kg |

| Bearing Type | 85mm tapered roller bearings (Timken/Koyo equivalent) |

| Flange Design | Double-flange with wear indicators |

| Seal System | Labyrinth + pressure-compensated grease channels |

| Weight | 185 kg per roller |

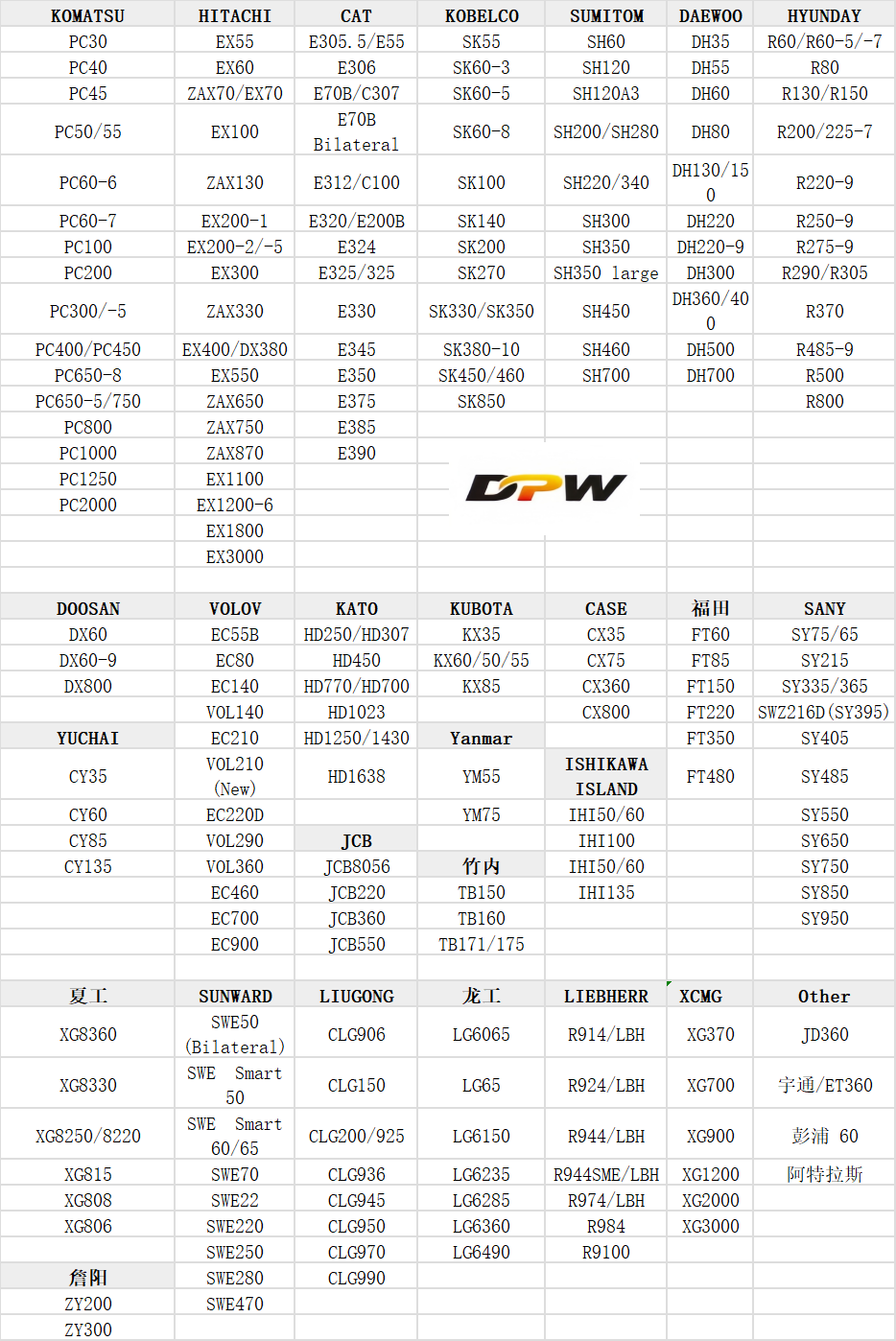

Compatible Models

Volvo EC950

Volvo EC950F

Volvo EC950B (Bridge Edition)

Volvo EC950

Volvo EC950F

Volvo EC950B (Bridge Edition)

Why Choose Genuine-Spec Bottom Rollers?

✅ 50% Longer Service Life – Compared to aftermarket alternatives

✅ Vibration Reduction – Precision-balanced for operator comfort

✅ Track Protection – Prevents premature chain/sprocket wear

✅ Global Availability – Supported by Volvo CE's parts network

When to Replace?

⚠ Flange wear >35% of original thickness

⚠ Visible cracks or spalling on rolling surfaces

⚠ Bearing play exceeding 3mm

⚠ Persistent grease leakage

Maintenance Protocol

Daily: Clear debris from flange grooves

Weekly: Check grease levels (Volvo P/N 1162389)

Monthly: Measure wear with flange gauges

Replace in Sets: Minimum 4 rollers for load balance

Daily: Clear debris from flange grooves

Weekly: Check grease levels (Volvo P/N 1162389)

Monthly: Measure wear with flange gauges

Replace in Sets: Minimum 4 rollers for load balance

Configuration Options

Standard (P/N 20980839) – General earthmoving

HD Mining Version (P/N 20980840) – Extra-thick flanges

Tungsten Carbide Coated (P/N 20980841TCC) – For extreme abrasion

Standard (P/N 20980839) – General earthmoving

HD Mining Version (P/N 20980840) – Extra-thick flanges

Tungsten Carbide Coated (P/N 20980841TCC) – For extreme abrasion

Upgrade Packages

▸ Telemetry Ready – RFID tags for wear monitoring

▸ Arctic Kit – -50°C rated seals (P/N 20980842AK)

▸ Extended Warranty – Up to 24 months available

Need Exact Pricing? Provide:

Machine serial number (e.g., EC950-5XXXXX)

Current roller P/N (if available)

Primary material handled (e.g., iron ore, oil sands)

Available with matching EC950 track chains (P/N 20980835) and sprockets (P/N 20980837) for complete undercarriage overhaul.

For ultra-severe conditions, ask about our EC950 Forged Bottom Roller Upgrade Program – combines forged durability with OEM precision tolerances.