Hitachi ZX850LC-3/4658418/Forged Front Idler Wheel Assembly/hot forging of alloy steel/Heavy-duty excavator undercarriage parts manufacture in quanzhou China.

Product Specifications

Premium Undercarriage Component for Mining & Heavy Construction

Product Overview:

The Hitachi ZX850LC-3 Forged Idler Wheel Assembly is a heavy-duty track guidance system component designed specifically for Hitachi's ZX850LC-3 excavator. This OEM-quality forged assembly ensures precise track alignment and optimal weight distribution in extreme operating conditions.

Key Features:

Advanced Forging Technology:

Manufactured from 34CrNiMo6 alloy steel (EN 10083-3 standard)

Hot-forged construction provides superior grain flow and 35% higher impact resistance than cast alternatives

Precision CNC machining ensures ±0.1mm dimensional accuracy

Enhanced Durability:

Induction-hardened flange surfaces (55-58 HRC)

Double-row tapered roller bearings (ISO 355:2017 compliant)

Triple-lip seal system with labyrinth protection (IP69K rated)

Performance Specifications:

Static load capacity: 12,500 kg radial / 5,800 kg axial

Fatigue life: >600,000 cycles (ISO 15653 testing)

Operating temperature range: -40°C to +120°C

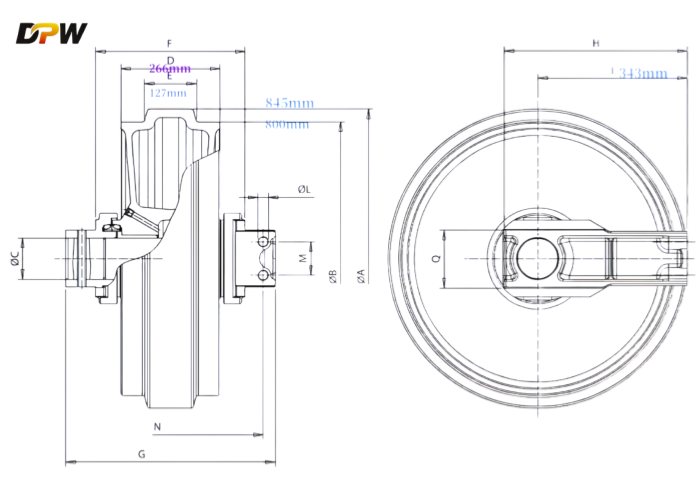

Technical Data:

| Parameter | Specification |

|---|---|

| Overall Width | 845mm ±1.5mm |

| Outer Diameter | 800mm ±0.8mm |

| Bearing Bore | 150mm H7 tolerance |

| Weight | 518kg ±2% |

| Bolt Pattern | 8xM24 on 420mm PCD |

Compatibility:

Direct replacement for OEM part number ZX850LC-3(4658418)

Compatible with ZX850LC-3, ZX870LCH-3, and ZX890LC-3 models

Interchangeable with aftermarket references: Berco TRK-850FI, ITM UND-850F

Maintenance Requirements:

Recommended greasing interval: 500 service hours (use Shell Gadus S2 V220 2)

Bearing inspection: Ultrasonic testing every 2,000 hours

Replacement indicators:

Flange wear >15mm

Bearing play >1.2mm

Seal leakage

Installation Guide:

Clean track frame mounting surfaces

Apply anti-seize compound to bolts (Loctite 243 recommended)

Torque sequence:

Initial: 580 N·m

Final: +90° rotation

Adjust track tension to 40-45mm sag

Quality Assurance:

100% magnetic particle inspection (ASTM E1444)

Material certification to EN 10204 3.2

12-month limited warranty

Packaging:

Wooden export crate (1000×800×600mm)

Gross weight: 550kg

Desiccant and VCI protection included

Available Through:

Hitachi Global Parts Network

Authorized undercarriage specialists

Certified aftermarket suppliers

Target Applications:

Mining operations

Heavy construction

Quarrying

Demolition work

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||