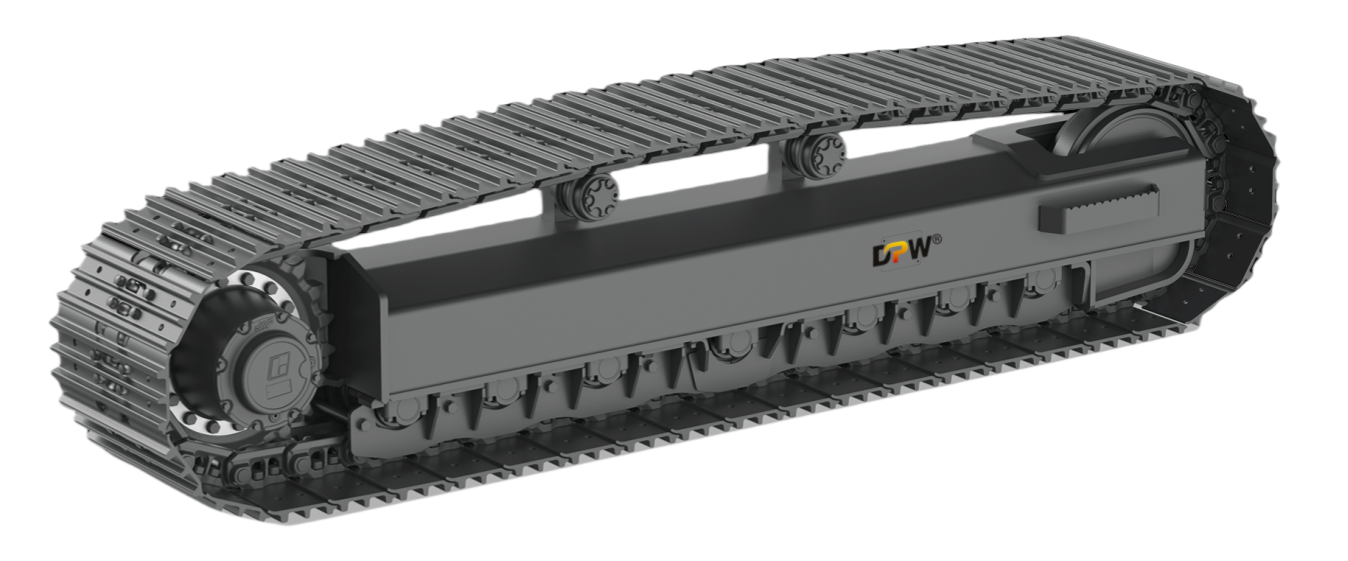

Caterpillar E375/E374/E385 Fabricated Idler Group/Forged Idler Assembly-Mining Construction Machinery parts first chioce

Product Specifications

(P/N:7Y-0856)Caterpillar E375/E374/E385/E390/E395 Forged Idler Group is a heavy-duty, forged steel assembly essential for supporting, guiding, and tensioning the tracks on a large Cat 375 excavator. Its forged construction provides the necessary strength and durability for demanding applications.

1. Core Definition & Function

What It Is: A heavy-duty welded steel assembly guiding/supporting tracks at the front of Cat 375 excavators.

Components Included:

Welded idler body (hub, flanges, side plates)

Shaft, bearings, seals, spacers, mounting brackets

Function:

Maintains track tension/alignment

Absorbs impacts & distributes machine weight (75+ tons)

Protects rollers/sprockets from premature wear

2. Fabricated vs. Forged: Key Design Differences

| Aspect | Fabricated Idler Group | Forged Idler Group |

|---|---|---|

| Manufacturing | Laser-cut steel plates welded together | Single-piece forged steel |

| Weight | 15–25% lighter | Heavier, monolithic construction |

| Cost | $2,800–$4,500 (30–50% lower than forged) | $5,500–$9,000 |

| Repairability | Modular – replace wear components (flanges) | Full-group replacement required |

| Best Applications | Moderate-duty: clay/loam soils, grading | Severe-duty: mining, quarries, rock |

3. Technical Specifications (E375-Specific)

Compatibility:

Cat® 375, 375B, 375C, 375D, 375F/L excavators

Serial Number Dependency: Critical for fit (e.g., 7ZR+ vs. MXP+ prefixes)

Materials:

AR400 steel wear surfaces

Labyrinth seals + heavy-duty tapered roller bearings

Dimensions:

Flange height: 750–820mm

Bore diameter: 80–100mm (varies by model)

4. Advantages of Fabricated Idlers

Cost Efficiency: Ideal for budget-conscious fleets without severe-duty needs

Serviceability: Individual components (flanges, seals) replaceable – reduces downtime

Weight Savings: Lowers fuel consumption + transport costs

Proven Performance: Meets Cat® engineering standards for B10 life in target applications

5. Limitations & Mitigation Strategies

Reduced Impact Resistance vs. forged idlers in rocky terrain:

Solution: Avoid high-impact sites or upgrade to forged

Shorter Lifespan in Abrasive Environments:

Mitigation: Use track guards, avoid silica-heavy soils

Typical Lifespan: 5,000–8,000 hrs (vs. 8,000–12,000 hrs for forged)

6. When to Choose Fabricated for Your E375

✅ Ideal Scenarios:

Urban construction (low-abrasion soils)

Landscaping, utility work

Machines with < 6,000 annual operating hours

Fleet cost-reduction initiatives

❌ Avoid If:Mining/quarrying primary application

Frequent rock excavation

Machine operates > 10 hrs/day in harsh conditions

7. Part Identification & Sourcing

OEM Part Numbers:

Example: 102-8136(E375), 135-8904 (375F) – Verify via S/N

Genuine Cat® Source:

Certified Aftermarket:

Brands: DPW,CQC (ensure ISO 9001 certification)

8. Pro Maintenance Tips

Inspection: Check flange wear every 500 hrs – replace if thickness < 50% OEM spec.

Lubrication: Use Cat TDTO-TMS oil (or equivalent) per OMM schedule.

Track Tension: Maintain 1.5–2.5" sag (per Cat SPEC) to reduce idler stress.

Final Verdict: The Cat E375 Fabricated Idler Group delivers optimal value for moderate-duty applications, offering significant cost savings without sacrificing engineering integrity. For severe conditions, forged remains king. Always reference machine S/N before purchase!