VOLVO EC460/480 Fabricated Front Idler Assembly/Forged steel profile-the first choice for mining chassis parts

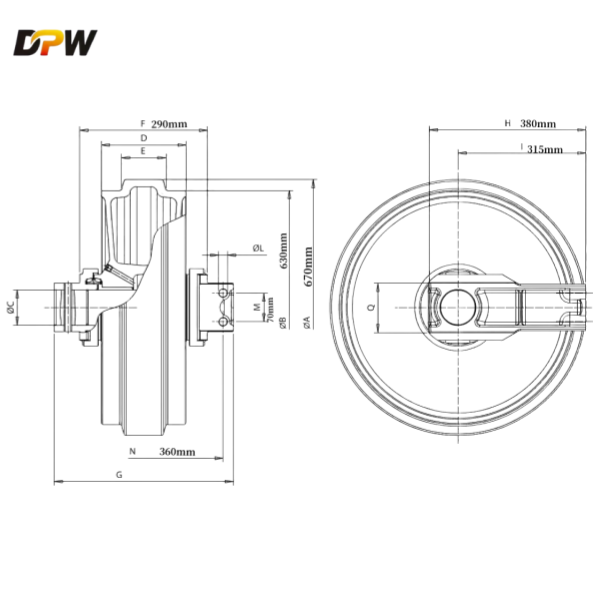

Product Specifications

The VOLVO EC460/480 Fabricated Front Idler Assembly with a forged steel profile is a robust and durable choice for mining chassis components, designed to withstand harsh operating conditions. Here’s why it stands out as the first choice for mining applications:

Key Features & Benefits:

Superior Strength & Durability

Forged Steel Construction: Provides higher strength, impact resistance, and fatigue life compared to cast or fabricated alternatives.

Heavy-Duty Design: Optimized for mining environments with high loads, shocks, and abrasive conditions.

Precision Engineering for Volvo EC460/480 Excavators

Exact OEM fitment ensures seamless integration with the undercarriage system.

Maintains proper track tension and alignment, reducing wear on other components.

Enhanced Wear Resistance

Hardened surfaces and premium materials extend service life, even in extreme mining conditions.

Resists deformation under heavy loads, ensuring long-term reliability.

Optimized Performance in Mining Applications

Handles high stress from rocky terrains, deep mud, and continuous operation.

Reduces downtime and maintenance costs compared to inferior idler designs.

Cost-Effective Long-Term Solution

Longer lifespan means fewer replacements, lowering total cost of ownership.

Compatible with aftermarket upgrades for improved performance.

Why Choose Forged Steel Over Cast or Fabricated Idlers?

Forged Steel: Higher density, fewer defects, and better grain structure for maximum durability.

Fabricated Idlers: May have welded seams that can crack under stress; forged idlers offer a monolithic structure.

Applications:

Ideal for mining, quarrying, and heavy construction where undercarriage components face extreme wear.

Suitable for Volvo EC460 & EC480 excavators operating in tough environments.

Conclusion:

For mining professionals seeking maximum durability, performance, and reduced downtime, the VOLVO EC460/480 Fabricated Front Idler Assembly with forged steel construction is the best choice. Its superior engineering ensures reliability in the most demanding conditions.

Would you like details on sourcing or comparing it with other undercarriage components?