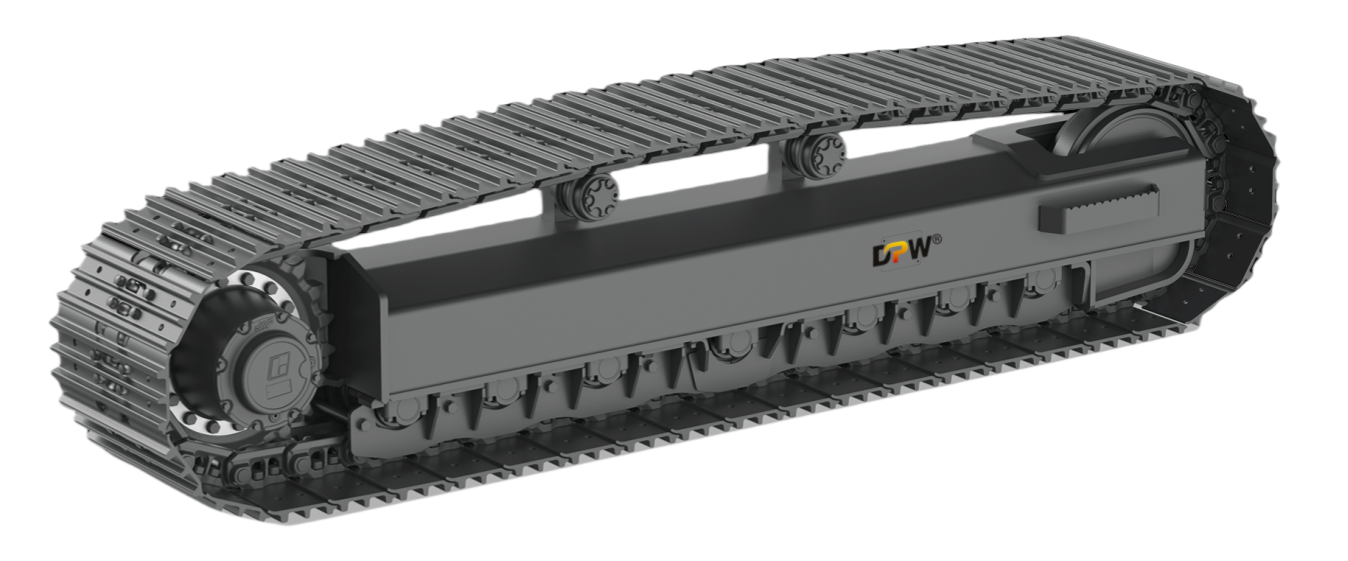

Hitachi-EX550/ZX650 Fabricated Idler Group/9137270/2044041/ compatible EX600/ZX500/ZX600/ZX650 Heavy duty excavator undercarriages

Product Specifications

Hitachi EX550 Undercarriage Fabricated Idler Group: Technical Overview

The Fabricated Idler Group is a critical structural component within the undercarriage system of Hitachi EX550-series hydraulic excavators. Engineered to endure extreme operational stresses in mining, quarrying, and heavy construction environments, it ensures track chain alignment, tension maintenance, and load distribution across the excavator’s lower frame.

1. Design & Construction

Fabricated Architecture: Unlike cast idlers, this group uses high-tensile steel plates (e.g., 28CrMnMo or 35SiMn alloy) laser-cut and robotically welded into a unified assembly. This design eliminates weak points (e.g., porosity in castings) and enhances fatigue resistance under cyclic impacts.

Integrated Flange System: Features reinforced flanges (30% thicker than standard idlers) to prevent track derailment during side-loading or uneven terrain traversal.

Sealed Bearing Housings: Utilizes triple-lip aluminum seals with labyrinth grease channels to exclude abrasive contaminants (e.g., silica dust, slurry) while minimizing friction-induced heat.

Fabricated Architecture: Unlike cast idlers, this group uses high-tensile steel plates (e.g., 28CrMnMo or 35SiMn alloy) laser-cut and robotically welded into a unified assembly. This design eliminates weak points (e.g., porosity in castings) and enhances fatigue resistance under cyclic impacts.

Integrated Flange System: Features reinforced flanges (30% thicker than standard idlers) to prevent track derailment during side-loading or uneven terrain traversal.

Sealed Bearing Housings: Utilizes triple-lip aluminum seals with labyrinth grease channels to exclude abrasive contaminants (e.g., silica dust, slurry) while minimizing friction-induced heat.

2. Technical Specifications

Parameter Value Source Compatible Models EX550, EX550LC-3, EX600-6, ZX650

Operating Weight 54,000–56,400 kg (EX550/LC-3 variants)

Shaft Hardness HRC 55-60 (induction-hardened)

Load Capacity Dynamic loads ≤50 tons (axial/radial)

Seal Type Multi-lip aluminum ring + PTFE dust shields

| Parameter | Value | Source |

|---|---|---|

| Compatible Models | EX550, EX550LC-3, EX600-6, ZX650 | |

| Operating Weight | 54,000–56,400 kg (EX550/LC-3 variants) | |

| Shaft Hardness | HRC 55-60 (induction-hardened) | |

| Load Capacity | Dynamic loads ≤50 tons (axial/radial) | |

| Seal Type | Multi-lip aluminum ring + PTFE dust shields |

3. Functional Role in Undercarriage System

Track Guidance: Positions the track chain precisely to prevent lateral slippage during slewing or slope operation.

Tension Management: Works with the track adjuster cylinder to maintain optimal track sag (typically 20–40 mm), reducing premature wear on sprockets and links.

Impact Absorption: Distributes ground-generated shocks (e.g., rock collisions) across the fabricated frame, protecting the excavator’s final drives and rollers.

Track Guidance: Positions the track chain precisely to prevent lateral slippage during slewing or slope operation.

Tension Management: Works with the track adjuster cylinder to maintain optimal track sag (typically 20–40 mm), reducing premature wear on sprockets and links.

Impact Absorption: Distributes ground-generated shocks (e.g., rock collisions) across the fabricated frame, protecting the excavator’s final drives and rollers.

4. Durability Enhancements

Heat Treatment: Raceways undergo carburizing and tempering to achieve core toughness (impact absorption) and surface hardness (wear resistance).

Corrosion Protection: Phosphate coating + epoxy paint layer resists oxidation in saline or high-humidity environments.

Lubrication System: Centralized greasing ports enable efficient re-lubrication without disassembly, using EP2 lithium-complex grease (ISO VG 220).

Heat Treatment: Raceways undergo carburizing and tempering to achieve core toughness (impact absorption) and surface hardness (wear resistance).

Corrosion Protection: Phosphate coating + epoxy paint layer resists oxidation in saline or high-humidity environments.

Lubrication System: Centralized greasing ports enable efficient re-lubrication without disassembly, using EP2 lithium-complex grease (ISO VG 220).

5. Failure Prevention & Maintenance

Common Failure Modes:

Seal Degradation: Hardened lips permit grit ingress → bearing spalling. Solution: Replace seals every 2,000 hours.

Flange Deformation: Caused by track over-tensioning. Solution: Maintain tension at OEM-specified 250–300 kPa.

Installation Protocol:

Mounting surfaces must be machined to H7/k6 tolerance to avoid preload-induced friction.

Use torque wrenches (not impact guns) on flange bolts (target: 980 N·m).

Common Failure Modes:

Seal Degradation: Hardened lips permit grit ingress → bearing spalling. Solution: Replace seals every 2,000 hours.

Flange Deformation: Caused by track over-tensioning. Solution: Maintain tension at OEM-specified 250–300 kPa.

Installation Protocol:

Mounting surfaces must be machined to H7/k6 tolerance to avoid preload-induced friction.

Use torque wrenches (not impact guns) on flange bolts (target: 980 N·m).

Technical Content Strategy

To align with Google’s 2025 quality guidelines, integrate these elements:

Semantic Entity Mapping

Core Entities: Undercarriage System → Track Chain → Sprocket → Carrier Rollers.

Related Concepts: Bearing Preload Tolerance, EP Grease Specifications, Track Tension Adjustment.

Core Entities: Undercarriage System → Track Chain → Sprocket → Carrier Rollers.

Related Concepts: Bearing Preload Tolerance, EP Grease Specifications, Track Tension Adjustment.

3. Authority-Building Content

Technical Guides:

"Optimizing Hitachi EX550 Undercarriage Lifespan: 5 Idler Maintenance Protocols [Case Study]."

Cross-Linking: Reference OEM manuals (e.g., Hitachi EX550-5 PDF specs).

Technical Guides:

"Optimizing Hitachi EX550 Undercarriage Lifespan: 5 Idler Maintenance Protocols [Case Study]."

Cross-Linking: Reference OEM manuals (e.g., Hitachi EX550-5 PDF specs).

4. Localization for Global Markets

Asia: Highlight compliance with Chinese GB/T 29717-2013 idler standards.

North America: Emphasize ASTM A572 Grade 50 steel material certification.

Asia: Highlight compliance with Chinese GB/T 29717-2013 idler standards.

North America: Emphasize ASTM A572 Grade 50 steel material certification.