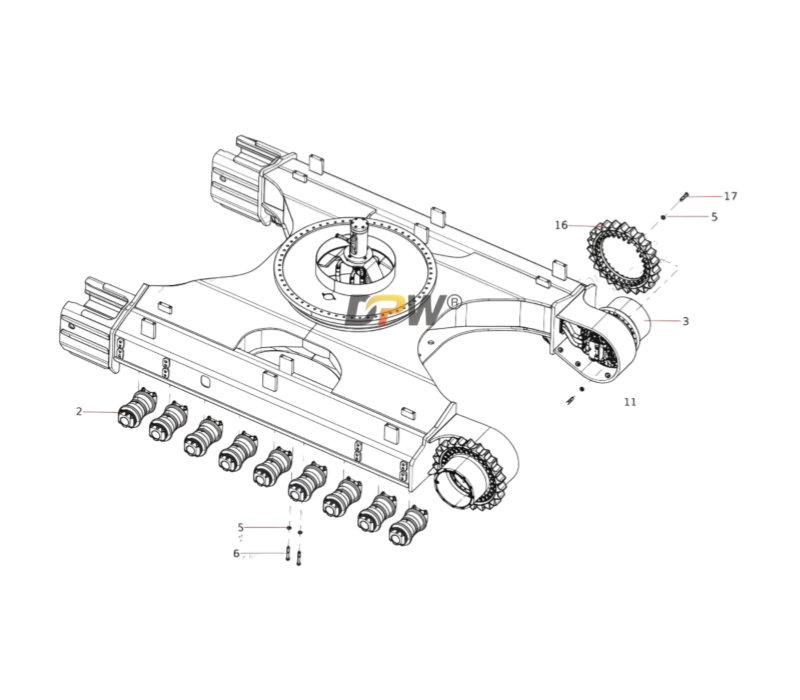

VOLVO 14343991/262612/5009091 EC140/W2100/D1600Track Bottom Roller Assy/OEM quality crawler chassis components source manufacturer and supplier

Product Specifications

Technical Specification: Track Roller / Bottom Roller Assembly

Part Identification:

Compatible Machine Models: VOLVO EC140, HYUNDAI/R140, WIRTGEN/W2100 Crawler Excavators;Drilling Rig etc.

Application: Undercarriage System, Lower Load-Bearing Structure.

Component Aliases: Bottom Roller, Lower Roller, Track Roller.

1.0 Component Overview

The Track Roller / Bottom Roller Assembly is a primary load-bearing component within the lower section of the excavator's undercarriage. Positioned on the bottom of the undercarriage frame, directly between the track chain and the frame, its fundamental role is to support the full operational weight of the machine and facilitate its smooth travel by carrying the lower strand of the track chain. These rollers are subjected to the most severe combination of static and dynamic loads, as well as constant exposure to abrasive materials.

2.0 Primary Function & Operational Context

The core engineering functions of this assembly are:

Primary Load Bearing: To carry and distribute the machine's weight (typically ranging from 14 to 16 tons for these models) through the track roller to the track chain and ultimately to the ground. They bear the brunt of the machine's static weight and dynamic shock loads from travel and operation.

Track Chain Guidance and Alignment: The flanges on the rollers guide the track chain, maintaining its longitudinal alignment and preventing lateral drift that could lead to derailment.

Ground Pressure Distribution: By supporting the track chain, they help distribute the machine's immense weight over a larger surface area, reducing ground pressure and preventing the machine from sinking into soft underfoot conditions.

Friction Reduction: They provide a hardened, durable rolling surface for the track chain links to run on, converting what would be sliding friction into significantly lower rolling friction, which improves travel efficiency and reduces power consumption.

3.0 Detailed Construction & Key Sub-Components

A Bottom Roller Assembly is a robust, sealed mechanism designed for high-load applications:

3.1 Outer Rim / Tread: The hardened circumferential surface that makes direct rolling contact with the track chain links. It is designed to withstand extreme abrasive wear.

3.2 Flanges: Integrated lateral guides on both sides of the tread. These flanges are critical for containing the track chain, preventing it from sliding off the roller during side-loading events like turning. They are subject to both impact and wear.

3.3 Stationary Shaft: A high-strength, hardened steel shaft that is pressed or bolted into the roller's mounting yoke. This shaft remains fixed and provides the axle for the rotating assembly.

3.4 Bearing System: A set of heavy-duty tapered roller bearings are mounted between the rotating roller body and the stationary shaft. These bearings are specifically selected for their high radial load capacity to support the machine's weight.

3.5 Multi-Stage Sealing System: This is the most critical subsystem for service life. It typically consists of a primary radial face seal, secondary dust lips, and often a labyrinth-style grease chamber. This robust system is designed to aggressively exclude abrasive contaminants (sand, mud, dust) and retain the high-performance grease within the bearing cavity. Seal integrity is the primary determinant of the roller's lifespan.

3.6 Housing and Mounting Yoke: The main body that encases the internal components and provides the attachment points to the undercarriage frame, often via bolts through the yoke.

4.0 Material & Performance Specifications

Material: High-Carbon or Alloy Steel Casting/Forging.

Hardness: The tread and flange contact surfaces are through-hardened or induction-hardened to a typical hardness of 55-60 HRC to provide exceptional resistance to abrasive wear and impact.

Lubrication: Pre-filled with a high-temperature, extreme-pressure (EP) lithium-complex grease. Most modern bottom rollers are equipped with a grease fitting (zerk) for periodic re-lubrication during service intervals, which helps to purge ingested contaminants and extend service life.

5.0 Failure Modes & Maintenance Considerations

Wear Limits: Serviceability is determined by measuring the reduction in flange height and tread diameter against VOLVO's specified maximum wear limits. Exceeding these limits risks track derailment and places undue stress on other undercarriage components.

Common Failure Modes:

Flange Wear: The inner sides of the flanges wear down due to constant contact with the track chain's guide guards.

Tread Wear (Grooving): The tread develops a concave wear pattern or deep grooves from abrasive friction with the track links.

Bearing Seizure or Excessive Play: Caused primarily by seal failure, which allows abrasive particles to contaminate the lubricant. A seized roller will not turn, acting as a brake and causing rapid, severe wear to the track chain. Excessive play indicates advanced internal wear.

Cracking or Spalling: Fatigue cracks or surface material flaking off the tread or flanges due to high-cycle stress and impact loads.

Maintenance Practice: Regular inspection is crucial. Rollers should spin freely by hand but without noticeable wobble. Any roller that is seized, has excessive play, or shows significant flange wear should be replaced immediately. Bottom rollers should be replaced in sets (all on one side) to ensure even load distribution and tracking. Their condition must be evaluated as part of the entire undercarriage system (track chain, sprocket, idler, carrier rollers).