HITACHI EX1800/ex1900 9173146 A7618000M00 Track Roller Assembly for heavy duty excavator undercarriage part

Product Specifications

Technical Exposition: Hitachi EX1800/EX1900-6 Undercarriage Track Bottom Roller Assembly

1. Introduction and Primary Function

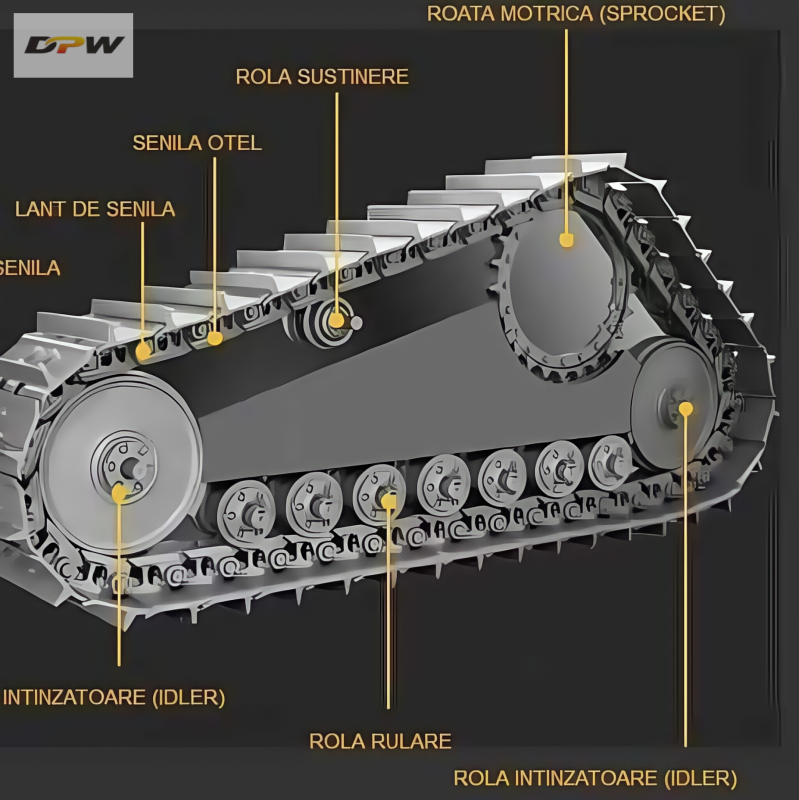

The Track Bottom Roller Assembly, also referred to as the lower track roller, is a critical structural and kinematic component within the undercarriage system of the Hitachi EX1800-6 and EX1900-6 mining shovels. Its primary functions are:

Load Bearing: To continuously support the gross machine weight—which exceeds 180 metric tons—by riding inside the lower flange of the track chain link. It acts as the primary intermediary between the track frame and the ground, transmitting immense static and dynamic loads.

Track Guidance and Alignment: To precisely guide the endless track chain, ensuring it remains aligned on the track roller path and meshes correctly with the sprocket and idler, thereby preventing derailment.

Oscillation Accommodation: As part of a bogie-style undercarriage common on these models, multiple bottom rollers are mounted on a pivoting bogie frame. This allows the undercarriage to oscillate over uneven terrain, maintaining ground contact and stability.

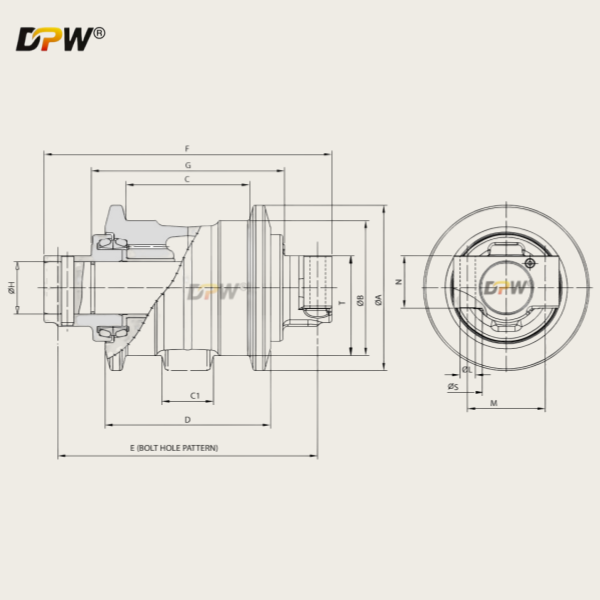

2. Detailed Component Breakdown and Engineering Specifications

The assembly is a sealed, lubricated-for-life unit comprising several precision-engineered sub-components:

| Component | Technical Description & Material Specification |

|---|---|

| Roller Shell / Body | • Function: The outer cylindrical surface that interfaces directly with the track link's wear surface. It features a double-flange design to contain the track link and prevent lateral slippage. • Manufacturing: Fabricated from high-carbon, high-chromium alloy steel (e.g., SAE 1055, 4140). • Treatment: Undergoes through-hardening or induction hardening to a typical surface hardness of 55-60 HRC, followed by precision grinding to achieve a fine surface finish for optimal wear and friction characteristics. |

| Stationary Shaft | • Function: Serves as the static central axle. It is rigidly mounted (press-fit and/or bolted) into the bogie frame and does not rotate. It is the foundation upon which all other components rotate or are seated. • Manufacturing: Machined from high-tensile strength alloy steel. • Features: Contains internal oil galleries and ports for lubrication. The mounting ends are often machined with precision tolerances for a secure interference fit. |

| Bushings / Sleeves | • Function: Act as the primary rotational wear surface. The roller shell rotates around these bushings, which are themselves stationary relative to the shaft. They are designed to withstand high radial loads. • Material: Typically comprised of oil-impregnated sintered bronze (oillite bushings) or case-hardened steel. Sintered bronze bushings provide self-lubricating properties, offering extended service life in case of primary seal failure. |

| Bearing System | • Configuration: Utilizes tapered roller bearings or, in some designs, relies on the precision clearance between the steel bushing and the shaft. • Function: Tapered roller bearings are specifically selected to manage both the immense radial loads from the machine's weight and the significant axial (thrust) loads generated during machine turning and side-sloping operation. |

| Sealing System | • Type: Employs a multi-stage, heavy-duty sealing system, most commonly a Duo-Cone seal. • Components: Consists of two precision-machined metal rings (one static, one rotating) that form a primary labyrinth seal, and secondary rubber O-rings or lip seals to provide a static seal. • Function: This is the most critical subsystem. It is designed to retain the internal lubricating grease and, more importantly, to completely exclude external contaminants such as abrasive dust, slurry, mud, and moisture. Seal integrity directly dictates the service life of the entire roller assembly. |

| End Caps / Covers | • Function: Serve as protective housings for the internal components and provide the mounting structure for the seal assemblies. They are securely fastened to the roller shell with high-strength cap screws. |

| Grease Fitting (Zerk Fitting) | • Function: Provides a standardized port for the introduction of lithium-complex EP (Extreme Pressure) grease during initial assembly and periodic maintenance to replenish the internal grease reservoir. |

3. Operational Failure Modes and Root Cause Analysis

Flange Wear: Progressive material loss on the roller's guiding flanges due to constant contact with the track link. Excessive wear reduces track guidance, leading to potential derailment and irregular load distribution.

Seal Failure and Contamination Ingress: The primary failure initiator. If the Duo-Cone seals are damaged or wear beyond their service limit, abrasive particles enter the assembly. This acts as a lapping compound, rapidly accelerating wear on bushings, shaft, and the roller shell's internal bore, leading to increased internal clearance.

Roller Seizure: Results from severe internal contamination or lubrication starvation. The roller ceases to rotate, transforming from a rolling element to a sliding one. This causes catastrophic, localized wear on the roller shell and the track link, often creating a flat spot on the roller.

Excessive Axial & Radial Play: Manifested as noticeable wobble or looseness of the roller. This is a direct consequence of internal component wear (bushings, bearings, shaft) and leads to imprecise track motion, increased impact loads, and accelerated wear on adjacent undercarriage components.

Structural Fracture: In extreme cases of shock loading or material fatigue, the roller shell or shaft may crack or break completely, resulting in immediate and catastrophic undercarriage failure.

4. Maintenance, Overhaul, and Replacement Protocol

Preventive Inspection: Daily visual checks for non-rotation, grease leakage (indicating seal compromise), and abnormal flange wear. Regular measurement of flange height and roller diameter against service limits is critical.

Correct Lubrication: Utilization of the specified high-temperature, high-pressure grease at recommended intervals. Over-greasing can damage seals, while under-greasing leads to insufficient lubrication and overheating.

Track Tension Management: Maintaining track tension according to manufacturer specifications is paramount. Overtightening increases rolling resistance and load on rollers and seals, while undertightening can cause whipping and uneven wear.

Replacement Strategy: Due to the interdependent nature of undercarriage components, it is standard and highly recommended practice to replace bottom rollers in matched sets on the same side. Replacing a single worn roller amidst others that are also worn can lead to uneven load distribution and rapid failure of the new component.

Rebuild vs. Replace: Worn rollers can often be rebuilt by specialized workshops. This process involves pressing out the old shaft, replacing all wear components (bushings, seals, end caps), and often building up and re-machining the roller shell to its original dimensions.

5. OEM and Aftermarket Considerations

OEM (CQC): Guarantees perfect dimensional conformity, material specification, and performance. It is the benchmark for quality and is typically required for new machine warranty compliance.

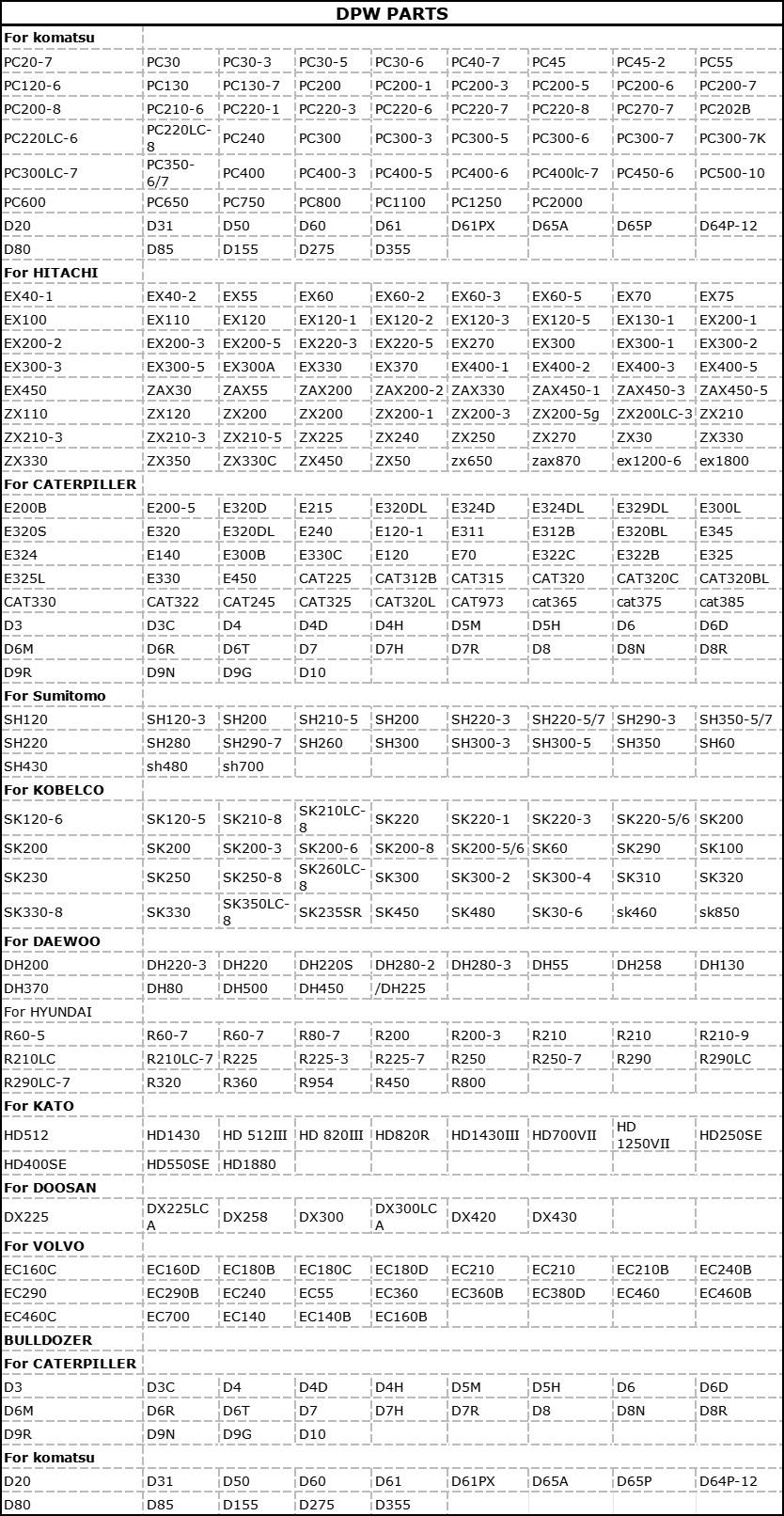

Aftermarket (DPW Parts): Offer a cost-effective alternative. Reputable manufacturers produce high-quality components that are often fully interchangeable with OEM parts. The critical factors are the quality of the raw materials, the precision of the heat treatment, and the robustness of the sealing system.

Application Scenarios

Copper/gold mine face loading

Oil sands overburden removal

Large-scale quarry operations

Dam construction projects