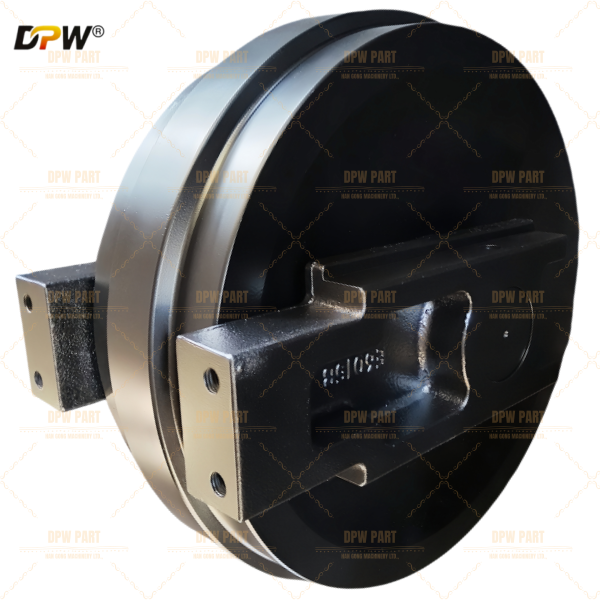

Caterpillar 6055861/4304193/4737850 LD350 E6015 Track Idler Wheel Assembly -/-Heavy-Duty Chassis Parts /HAN GONG / DPW PARTS in Quanzhou China

Product Specifications

Introduction to the Front Idler’s Role in Track Chassis Stability

The track idler wheel, positioned at the front of an excavator’s undercarriage, is a fundamental chassis component that serves multiple critical engineering functions. It acts as a primary guide for the track chain, maintains optimal track tension and alignment through its adjustable mounting, and absorbs substantial forward impact loads during operation. For Caterpillar 350 Series machines, including models like the LD350, E6015, and E6015B, a robust idler assembly is vital for stabilizing the entire track system, preventing derailment, and ensuring efficient power transfer from the drive sprocket.

Product Specification: Caterpillar Track Idler Wheel Assembly

This assembly is engineered as a direct, dimensionally precise replacement for the OEM component, ensuring full compatibility and performance integrity for targeted Caterpillar models.

OEM Part Number Cross-Reference: 6055861, 4304193, 4737850.

Target Machine Applications: Caterpillar 350 Series Hydraulic Excavators, including but not limited to models LD350, E6015, E6015B, and their variants.

Component Identification: Front Track Idler Wheel, Complete Assembly.

Core Function: To guide the track chain, provide a point for track tension adjustment, absorb longitudinal shocks, and support machine weight in conjunction with rollers and sprockets.

Engineering & Manufacturing Analysis by HAN GONG / DPW PARTS

Based in Quanzhou, China—a global hub for construction machinery components—HAN GONG (marketed under DPW PARTS) is a specialized manufacturer focused on heavy-duty undercarriage systems. Their production of the Caterpillar 6055861 Idler Assembly follows a stringent engineering protocol tailored for severe-duty cycles.

1. Material Selection & Forging Process:

The idler body is forged from high-grade boron or alloy steel (e.g., 50Mn, 55Mn2). This forging process ensures a superior internal grain structure, providing exceptional yield strength and impact toughness to withstand the constant pounding and bending stresses encountered in rock and demolition work.

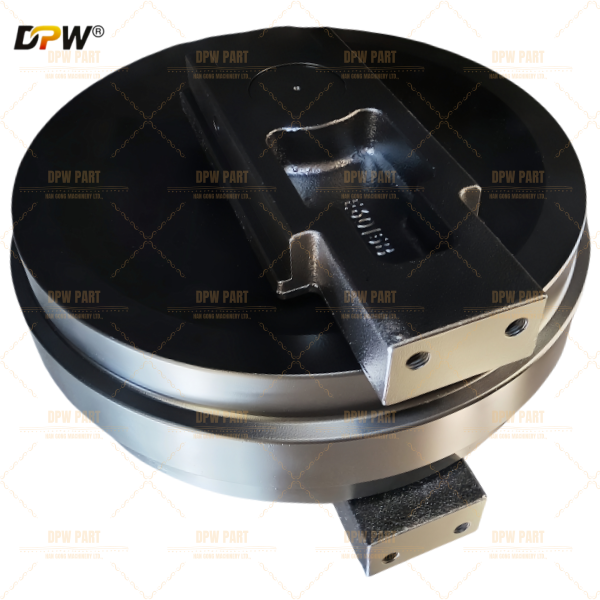

2. Precision Machining & Advanced Hardening:

CNC Machining: Post-forging, the component undergoes meticulous CNC machining to achieve exact tolerances for the hub bore, flange profiles, and overall concentricity. This precision is critical for smooth rotation and proper seal alignment.

Differential Hardening: The idler’s outer rim and guiding flanges undergo induction hardening to achieve a deep, uniform surface hardness (typically 55-60 HRC). This creates a wear-resistant layer that effectively resists abrasion from the track chain bushings, while the core retains its ductility to absorb impact energy without cracking.

3. Integrated Sealing & Bearing System:

The assembly incorporates a multi-labyrinth seal design combined with heavy-duty floating metal face seals (often styled after Duo-Cone seals). This system is engineered to exclude abrasive contaminants like sand, clay, and rock dust, while reliably retaining high-viscosity, high-temperature grease within the bearing chamber.

The internal bearing system typically utilizes large-diameter tapered roller bearings or journal bushings, selected for their high radial load capacity and longevity when protected by an effective sealing solution.

4. Complete Assembly & Corrosion Protection:

HAN GONG supplies the idler as a fully assembled, pre-lubricated unit. This includes the hardened idler body, internal bearings, seals, spacers, and often the mounting bushings (if not part of the track frame).

Surfaces are treated with protective coatings or primer to prevent corrosion during shipping and storage, ensuring the component is in optimal condition for installation.

Operational Advantages & Failure Mode Prevention

A high-quality idler wheel mitigates common failure modes:

Premature Flange Wear: Advanced hardening extends flange life, preventing rapid wear that leads to track misguidance.

Seal Failure & Bearing Contamination: The robust multi-barrier seal system is the primary defense against the leading cause of idler seizure.

Rim Cracking or Deformation: The forged, toughened steel construction resists the high-impact loads that can cause catastrophic failures.

Why Source from HAN GONG / DPW PARTS in Quanzhou?

Specialized Manufacturing Focus: As a dedicated undercarriage parts manufacturer, their processes and quality controls are specifically designed for high-stress chassis components.

Vertical Production Control: Oversight from forging to final assembly allows for consistent quality and traceability.

Cost-to-Performance Value: Provides a reliable, OEM-compatible alternative that meets the performance demands of heavy-duty applications, offering significant value for maintenance and repair operations.

Supply Chain Efficiency: Located in a major industrial cluster, they offer streamlined logistics and supply reliability for global distributors and large end-users.

Maintenance and Compatibility Guidance

Paired Replacement: For optimal undercarriage life and performance, the idler should be inspected and replaced in concert with the track chain, rollers, and sprockets to avoid mismatched wear profiles.

Proper Tensioning: During installation, track tension must be adjusted according to the manufacturer’s specifications to prevent undue stress on the idler bearings and ensure proper machine steering and stability.

Conclusion

The Caterpillar 6055861 / 4304193 / 4737850 Track Idler Wheel Assembly is a cornerstone component for the stability and longevity of 350 Series excavator undercarriages. HAN GONG / DPW PARTS, leveraging the industrial capabilities of Quanzhou, manufactures this critical part with a focus on material integrity, precision engineering, and sealed-for-life performance. For fleet managers and equipment service providers seeking dependable heavy-duty chassis components, this manufacturer represents a source capable of delivering the durability required to minimize downtime and optimize the total cost of ownership for Caterpillar 350 Series excavators.

- Hydraulic Mining Shovel caterpillar CAT6015 Track links assy CAT6015 track chains

- Hydraulic Mining Shovel caterpillar CAT6015 Track group CAT6015 track shoes assy 47L 700MM 430-4199

- Hydraulic Mining Shovel caterpillar CAT6015 Track shoes

- Hydraulic Mining Shovel caterpillar CAT6015 Track rollers 2307162 CAT6015 bottom rollers 230-7162 CAT6015 lower rollers

- Hydraulic Mining Shovel caterpillar CAT6015 Carrier rollers 4304195 CAT6015 upper rollers 430-4195 CAT6015 top rollers

- Hydraulic Mining Shovel caterpillar CAT6015 sprocket

- Hydraulic Mining Shovel caterpillar CAT6015 Sprocket bolts 7X-2586

- Hydraulic Mining Shovel caterpillar CAT6015 track bolts

- Hydraulic Mining Shovel caterpillar CAT6015 track nuts

- Hydraulic Mining Shovel caterpillar CAT6015 Bucket Adapter 572-0861 5720861 Weld-On M75 Two Strap Adapter repair China suppliers

- Hydraulic Mining Shovel caterpillar CAT6015 Bucket Adapter 572-0862 5720862 Weld-On M75 Two Strap Straddle Adapter – LH China suppliers

- Hydraulic Mining Shovel caterpillar CAT6015 Bucket Adapter 572-0863 5720863 Weld-On M75 Two Strap Straddle Adapter – RH aftermarket China suppliers