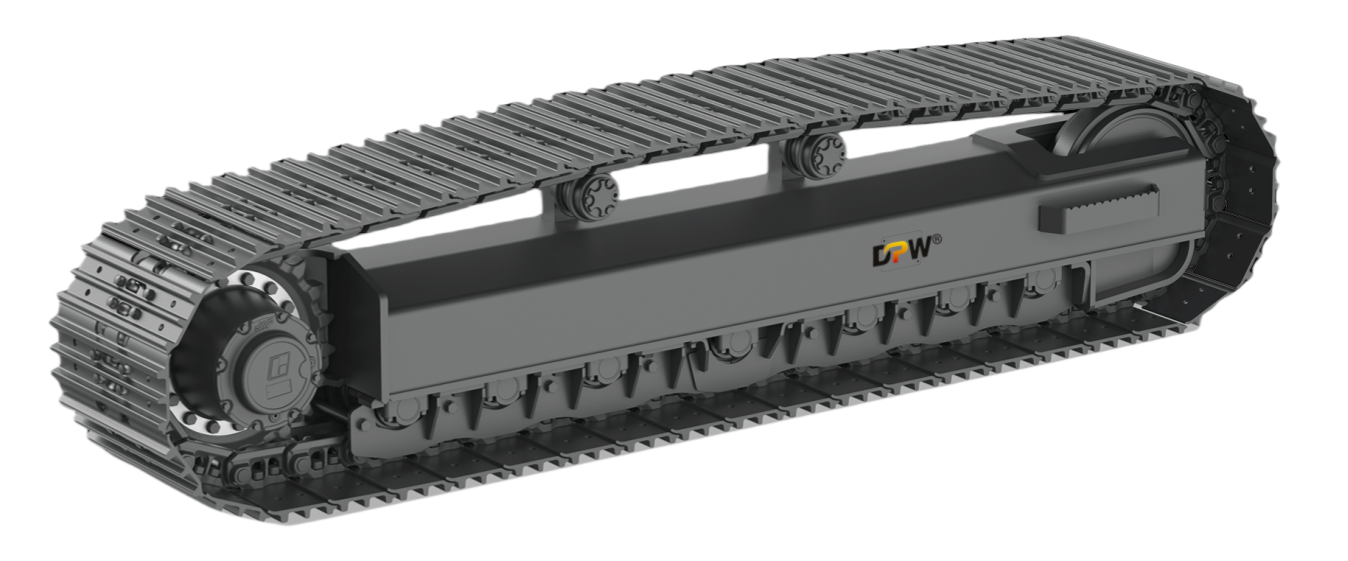

SHANTUI/8260-MC-A1000/SE750 SE680 SE800 Track Bottom/Lower Roller Assy

Product Specifications

Comprehensive Technical Overview: SHANTUI SE680/750/800 Track Roller Assy(8260-MC-A1000)

1. Product Definition and Primary Function:

The SHANTUI Track Roller Assy (Assembly) for models SE680, SE750, and SE800 is a critical undercarriage component specifically engineered for large-sized excavators. Its primary function is to support the weight of the entire machine and guide the track chain along the track frame. It ensures stable, smooth, and efficient travel and operation over diverse and often challenging terrains encountered in heavy-duty applications like mining, quarrying, and large-scale construction.

2. Key Components of the Assembly:

A complete Track Roller Assy is a sealed and pre-lubricated unit, typically consisting of the following integral parts:

Outer Rim/Tire: The hardened, durable outer surface that makes direct contact with the track chain links. It is designed for maximum wear resistance.

Flanges: The raised edges on both sides of the roller that keep the track chain properly aligned, preventing derailment during turns and on uneven ground.

Hub: The central part that houses the internal components and connects to the mounting hardware.

Seals (Extremely Critical): Multi-layered, heavy-duty labyrinth seals (often including oil seals and O-rings). These are vital for preventing the ingress of abrasive contaminants (like dirt, dust, mud, and water) and for retaining the internal lubricant. The quality of the seals directly determines the service life of the entire assembly.

Bearings: High-capacity, tapered roller bearings or journal bearings that allow the roller to rotate smoothly with minimal friction around a fixed axle.

Axle Shaft/Bushing: The stationary shaft upon which the roller and bearings rotate. It is securely mounted to the track frame.

Internal Lubricant: High-quality, high-temperature grease specifically designed for undercarriage components, providing continuous lubrication to the bearings and reducing wear.

3. Compatibility and Application:

This assembly is designed to be interchangeable (with verification of specific product codes) across the following SHANTUI large Excavator models:

SHANTUI SE680

SHANTUI SE750

SHANTUI SE800

These machines are high-horsepower, robust excavtors used in the most demanding earth-moving projects, requiring undercarriage components of the highest durability and reliability.

4. Material and Manufacturing Technology:

Material: Manufactured from high-carbon, high-chromium alloy steel (e.g., 50Mn, 60Si2Mn). The outer rim undergoes specialized heat treatment processes like induction quenching or case carburizing. This creates an extremely hard, wear-resistant outer surface (often reaching 55-60 HRC) while maintaining a tougher, more shock-absorbent core.

Precision Machining: Components are machined to precise tolerances to ensure perfect fitment, balance, and smooth rotation, minimizing vibration and uneven wear.

Sealing Technology: Advanced multi-path labyrinth sealing systems are employed, often utilizing wear-resistant seal rings and high-performance nitrile rubber (NBR) to achieve an exceptional IP rating against contaminants.

5. Key Performance Characteristics and Advantages:

Exceptional Wear Resistance: The hardened material and robust construction significantly extend service life, reducing downtime and cost-per-hour of operation.

Superior Sealing: Effective sealing is the cornerstone of longevity, protecting the critical internal bearings from premature failure.

High Load-Bearing Capacity: Engineered to withstand the immense static and dynamic loads generated by multi-ton bulldozers.

Impact Resistance: The tough core material absorbs shocks from obstacles like rocks and debris, preventing cracking and catastrophic failure.

Excellent Stability and Guidance: Precisely machined flanges ensure optimal track alignment, improving machine travel efficiency and safety.

Interchangeability: Designed to OEM specifications for easy replacement and compatibility with the specified SHANTUI models.

6. Importance of Maintenance and Genuine Parts:

Using a genuine SHANTUI or OEM-quality equivalent Track Roller Assy is crucial. Inferior parts may have poor material quality, inadequate heat treatment, and substandard seals, leading to rapid wear, unexpected failure, and potential damage to other undercarriage components like the track chain and sprockets.

Regular undercarriage inspection for wear and damage is essential for optimal machine performance and safety.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||