SANY SY980 Track Final Drive Sprocket Assy/Drive Wheel/heavy duty Mining excavator chassis components source factory and manufacturer-DPW Parts

Product Specifications

Technical Specification: Track Drive Sprocket Assembly (Drive Wheel)

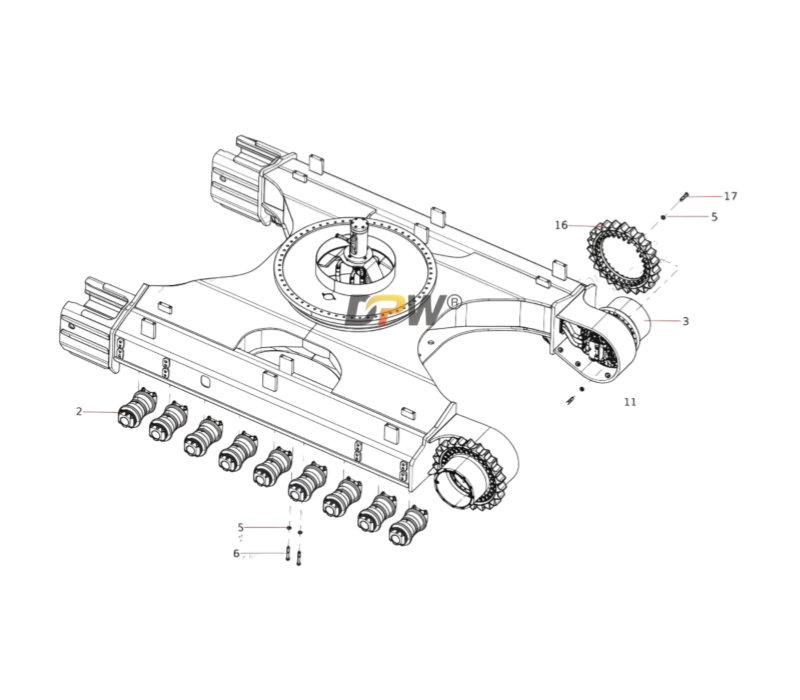

Part Identification:

Compatible Machine Model: SANY SY980 Hydraulic Excavator.

Application: Final Drive and Track System.

Component Aliases: Drive Sprocket, Drive Wheel, Track Sprocket Assembly.

1.0 Component Overview

The SANY SY980 Track Drive Sprocket Assembly, commonly referred to as the Drive Wheel, is the primary power output component of the excavator's travel (undercarriage) system. Mounted directly to the output flange of the final drive motor, its fundamental function is to convert the final drive's high-torque rotational energy into linear motion by engaging with and propelling the track chain. It is the active component that drives the entire track system, making it critical for the machine's mobility, traction, and operational stability.

2.0 Primary Function & Operational Context

The core functions of this assembly are:

Power Transmission: To mesh with the track chain bushings (the "pins" of the chain) and transmit the rotational force from the final drive, thereby pulling the track chain around the undercarriage circuit.

Kinetic Energy Conversion: To act as the final interface that transforms hydraulic and mechanical energy from the power train into the kinetic energy required for machine travel.

Load Distribution: To withstand immense tensile forces generated by the pulling action on the track chain, as well as shock loads from uneven terrain and abrupt directional changes.

3.0 Detailed Construction & Key Sub-Components

This is a robust, integrated assembly typically comprising:

3.1 Sprocket Wheel (The Toothed Rim): This is the main toothed element. The teeth are precision-machined to perfectly match the pitch of the track chain bushings.

Tooth Profile: The contour is engineered for optimal engagement and force distribution, minimizing stress concentration on the track chain bushings.

Material & Hardness: Fabricated from high-carbon or alloy steel (e.g., 41Cr4) and undergoes heat treatment processes like induction hardening. This results in an extremely hard, wear-resistant tooth surface (typically 55-60 HRC) to resist abrasion, while the core remains tough to absorb impacts and prevent tooth fracture.

3.2 Hub (Mounting Center): The central structure that connects the sprocket to the final drive. It features a precisely machined pilot diameter and a bolt circle pattern to ensure perfect alignment and a rigid connection.

3.3 Mounting Hardware: High-strength, pre-tensioned bolts and often a locking plate are used to secure the assembly to the final drive's output flange. The integrity of this connection is paramount for safe operation.

4.0 Material & Performance Specifications

Material: High-Quality Alloy Steel Casting or Forging.

Heat Treatment: Through-hardening or selective induction hardening of the sprocket teeth to achieve a deep, uniform case hardness for maximum service life.

Dimensional Integrity: Manufactured to precise geometric tolerances to ensure perfect meshing with the track chain, which is vital for smooth power transfer, reduced noise, and minimized vibration.

5.0 Failure Modes & Maintenance Considerations

Wear Progression: The primary wear mechanism is the gradual thinning and deformation of the sprocket teeth due to abrasive and adhesive wear against the track chain bushings. A well-maintained sprocket will wear evenly across the entire tooth profile.

Common Failure Modes:

Tooth Wear (Hook Form): The leading (pressure) flank of the teeth wears down, creating a sharp, hooked profile. This improper geometry leads to poor engagement, accelerated wear on the new or used track chain, and increases the risk of track "climbing" and derailment.

Tooth Chipping or Fracture: Caused by extreme impact loads, material fatigue, or operating with an overly tight or loose track.

Bolt Loosening/Shearing: A critical failure mode often resulting from improper installation torque, failed lock plates, or extreme operational shocks, which can lead to the assembly detaching from the final drive.

Maintenance Synergy (The "System" Approach): The service life of the drive sprocket is inextricably linked to the condition of the track chain and other undercarriage components (rollers, idlers). Replacing a worn sprocket in conjunction with a new track chain is a standard best practice. Installing a new sprocket against a worn chain (or vice versa) will cause rapid, accelerated wear on both components due to mismatched pitch.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||