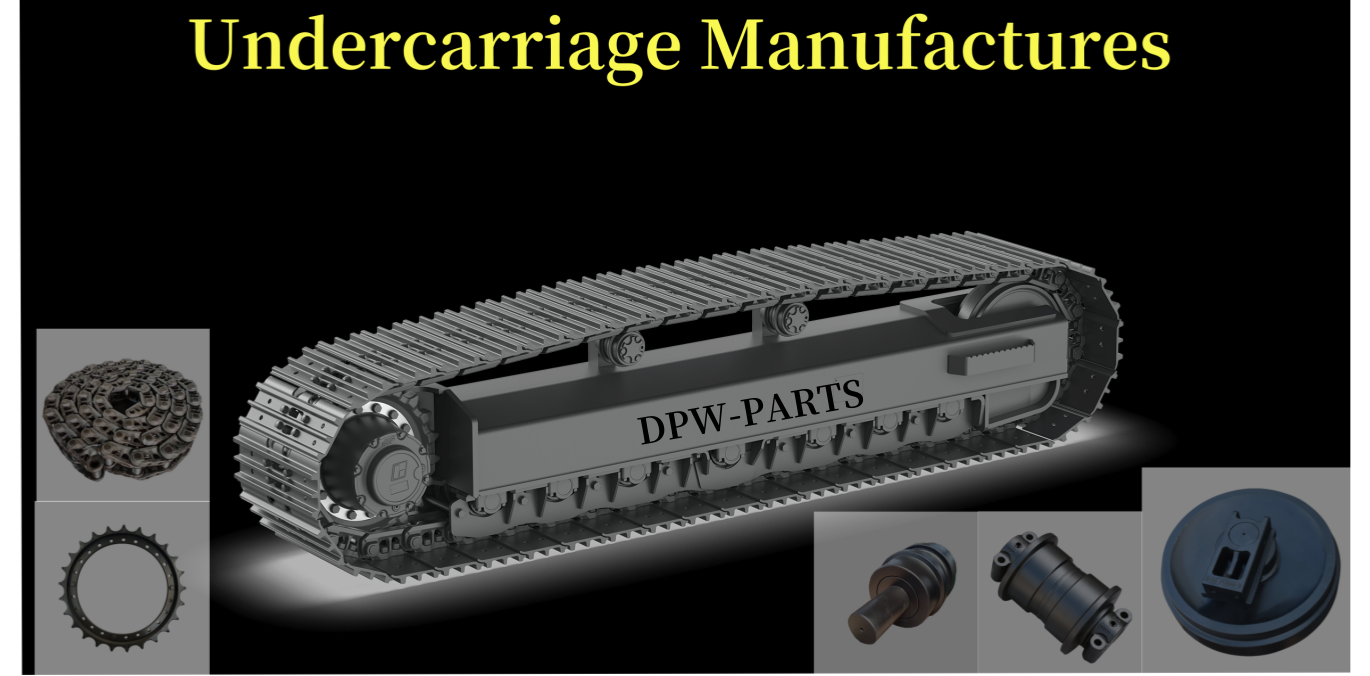

SANY-SY485 Forged Front Idler Assembly for heavy-duty construction equipment undercarriage parts/Forged idler factory/manufactures/supplier.

Product Specifications

1. Definition & Core Function

The SANY-SY485 Forged Idler Assy (Assembly) is a critical undercarriage component specifically engineered for SANY’s SY485 crawler excavator (typically a 48.5-ton class machine). It serves as the front idler wheel, guiding the excavator’s continuous track chain, maintaining proper track tension, and supporting the machine’s weight while distributing operational loads across the undercarriage system.

2. Key Manufacturing Process: Forging

Material: High-carbon alloy steel (e.g., SAE 1045, 4140, or equivalent proprietary grades).

Process: The core idler wheel is manufactured using hot forging. Molten steel is pressed under extreme pressure within precision dies.

Advantages vs. Casting:

Superior Strength & Durability: Forged grain structure aligns with component shape, significantly enhancing impact resistance and fatigue strength.

Increased Density: Fewer internal voids/inclusions, leading to greater structural integrity.

Enhanced Wear Resistance: Better withstands abrasion from track chain links and ground debris.

Longer Service Life: Fundamental for high-stress mining, quarrying, and heavy construction applications.

3. Assembly Components & Structure

The "Assembly" typically consists of:

Forged Idler Wheel: The primary load-bearing and track-guiding component. Features precisely machined flanges to retain the track chain.

Idler Shaft: A hardened steel shaft running through the wheel's center bore, transmitting loads to the track frame.

Bearings: Heavy-duty tapered roller bearings or spherical roller bearings, enabling smooth rotation under immense radial and axial loads.

Seals: Multi-labyrinth or floating face seals (often combined with grease purging), preventing contamination (dirt, water, abrasives) from entering the bearing cavity – critical for longevity.

Housings/Bushings: Robust housings (often welded or bolted) connect the idler to the excavator’s track frame. May include bushings for the tensioning mechanism.

Lubrication Fittings: Grease zerks for routine maintenance of bearings and seals.

Fasteners: High-strength bolts, nuts, and washers securing all components.

4. Critical Functions in the Undercarriage System

Track Guidance: Ensures the track chain runs true and aligned, preventing derailment.

Track Tension Maintenance: Acts as the adjustable front point for the track chain. Connected to the track tensioner cylinder/mechanism.

Load Distribution: Bears a significant portion of the machine's weight and dynamic loads (shocks from uneven terrain, digging forces transmitted through the frame).

Impact Absorption: Absorbs shocks when the track contacts obstacles.

Ground Clearance: Helps define the machine's clearance height.

5. SANY-SY485 Specific Design & Features

Optimized Dimensions: Precisely engineered diameter, width, and flange height to match the SY485’s specific track chain pitch, link height, and overall undercarriage geometry.

High Load Capacity: Designed to withstand the static and dynamic loads generated by the 48.5-ton excavator during digging, lifting, travel, and swing operations.

Robust Sealing: Advanced sealing systems tailored for harsh environments common in SY485 applications (mud, dust, rocks, water immersion).

Tensioning Interface: Designed to integrate seamlessly with the SY485’s hydraulic or grease-based track tensioning system.

Mounting Configuration: Specific bolt pattern and interface dimensions to match the SY485 track frame.

6. Importance of Genuine/OEM Compatibility

Precision Fit: Guarantees perfect alignment with the track chain, sprocket, rollers, and track frame, preventing accelerated wear on all components.

Optimal Performance: Ensures designed load capacity, sealing effectiveness, and tensioning functionality.

Warranty Compliance: Use of genuine SANY parts is often required to maintain warranty coverage.

Lifecycle Cost: While potentially higher initial cost, the superior durability and fit of a genuine forged idler assembly reduce total cost of ownership by extending service intervals and preventing collateral damage.

7. Applications & Operating Environment

Primary Machine: SANY SY485 Crawler Excavator.

Typical Industries: Heavy construction (road building, site prep), mining (coal, quarry), demolition, large-scale earthmoving, forestry.

Harsh Conditions: Designed to operate reliably in abrasive environments (rocky soil, sand), muddy/wet conditions, extreme temperatures, and under high impact loads.

8. Failure Modes & Consequences

Wear: Flange wear (from track link contact), bore wear (from shaft/bearings), seal wear.

Bearing Failure: Due to contamination, lack of lubrication, or overload.

Seal Failure: Leading to rapid bearing contamination and failure.

Cracking/Fracture: Caused by severe impact or material fatigue (less likely in forged vs. cast).

Consequences: Track derailment, damage to other undercarriage components (track links, rollers, sprocket), unplanned downtime, costly repairs, safety hazards.

9. Maintenance Requirements

Regular Inspection: Check for abnormal wear, cracks, oil/grease leaks, and track tension.

Lubrication: Adhere strictly to SANY’s recommended lubrication schedule (type and volume of grease) for bearings and seals.

Track Tension: Maintain proper tension (as per operator's manual) – too loose causes derailment risk and component slap; too tight accelerates wear and increases power consumption.

Cleanliness: Keep the area around seals as clean as possible.