SANY SSY004997367 SY850/SY870 UndercarriageTrack Drive Sprocket Assembly/OEM quality chassis components manufacturer-DPW Prats

Product Specifications

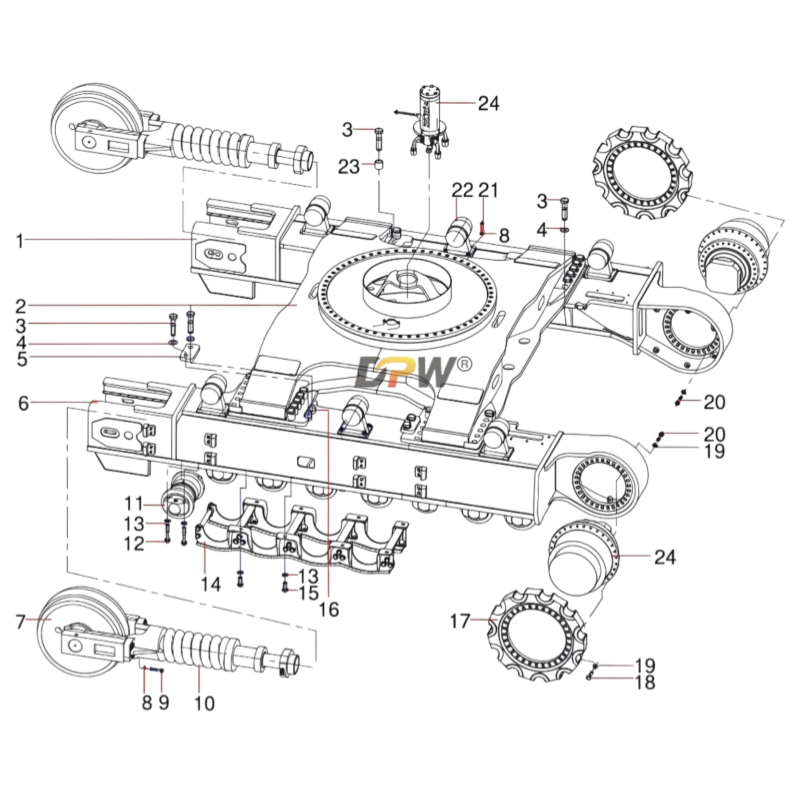

Technical Data Sheet: Track Drive Sprocket Assembly

Part Identification:

OEM Part Number: SSY004997367

Compatible Machine Models: SANY SY850, SANY SY870 Hydraulic Excavators.

Application: Final Drive and Track Propulsion System.

Component Aliases: Drive Sprocket, Drive Wheel, Travel Sprocket.

1.0 Component Overview

The Part Number SSY004997367 is a Track Drive Sprocket Assembly, a mission-critical component within the undercarriage system of large-scale hydraulic excavators. This assembly serves as the definitive power transmission interface, directly engaging with the track chain to convert the high-torque rotational output of the final drive into the linear motion required for machine travel. It is the active element that "drives" the entire track circuit around the undercarriage, making it indispensable for the machine's mobility, traction, and operational capability.

2.0 Primary Function & Operational Context

The core engineering functions of this assembly are:

Torque Transmission: To mesh precisely with the track chain's bushings (the hardened, cylindrical pins that form the chain's pitch line) and transmit the immense rotational force from the final drive's output shaft.

Track Propulsion: As the sprocket rotates, its teeth pull the track chain, causing it to circulate around the path defined by the idler, track rollers, and carrier rollers, thereby propelling the machine.

High-Stress Load Management: It is engineered to withstand extreme forces, including:

Shear Stress: From the transmission of engine and hydraulic power.

Tensile Stress: Generated by the pulling action on the track chain.

Impact Loads: Resulting from engaging with the chain bushings and encountering uneven ground or obstacles.

3.0 Detailed Construction & Key Sub-Components

This is a robust, integrally designed assembly typically consisting of:

3.1 Sprocket Wheel (Toothed Rim): The primary working component. Its teeth are precision-machined to a specific profile and pitch that exactly match the track chain.

Tooth Profile: Engineered for optimal force distribution and smooth engagement/disengagement with the track chain bushings to minimize shock and noise.

Material & Hardness: Fabricated from high-carbon or alloy steel (e.g., AISI 4140 or similar) and undergoes rigorous heat treatment like induction hardening. This process creates an extremely hard, wear-resistant tooth surface (typically 55-62 HRC) to resist abrasion, while the core material remains ductile to absorb high-impact loads and prevent catastrophic tooth fracture.

3.2 Hub (Mounting Interface): The central structural element that provides the connection point to the final drive. It features a machined pilot diameter for precise concentric alignment and a drilled bolt circle for secure attachment.

3.3 Mounting Hardware: High-strength, pre-tensioned bolts, often used in conjunction with a locking plate or prevailing torque nuts, are critical for maintaining a rigid connection between the sprocket and the final drive flange under severe and fluctuating torque conditions.

4.0 Material & Performance Specifications

Material: High-Strength Alloy Steel, typically produced as a casting or forging to ensure grain flow continuity and superior mechanical properties.

Heat Treatment: Selective induction hardening of the sprocket teeth is employed to achieve a controlled depth of hardness, balancing a wear-resistant surface with a tough, impact-absorbing core.

Dimensional Integrity: Manufactured to strict geometric and tolerance standards to guarantee perfect pitch-matching with the track chain. This precision is vital for efficient power transfer, minimized vibration, and prevention of abnormal wear patterns.

5.0 Failure Modes & Maintenance Considerations

Wear Progression: The primary wear mechanism is the gradual material loss from the sprocket teeth's pressure flanks due to rolling and sliding contact with the harder track chain bushings. Under ideal conditions, wear is uniform across the tooth profile.

Common Failure Modes:

Hooking (Undercutting): The leading flank of the teeth wears down, forming a sharp, hooked profile. This deformed geometry impedes smooth chain engagement, promotes accelerated wear on a new or used track chain, and significantly increases the risk of track "climbing" and derailment.

Tooth Chipping or Fracture: Caused by excessive impact loads, material fatigue, or operating with incorrect track tension.

Root Cracking: Fatigue cracks initiating at the root of the teeth due to cyclic bending stresses.

Bolt Failure: Loosening or shearing of mounting bolts due to improper torque, failed locking mechanisms, or extreme shock loads, potentially leading to assembly separation.

Preventive Maintenance & System Synergy: The drive sprocket's lifespan is directly tied to the condition of the entire track chain system. The standard best practice is to replace the drive sprocket as a set with the track chain (and often the idler and rollers) to prevent accelerated, premature wear due to pitch mismatch. Regular inspections for tooth profile deformation, cracks, and bolt integrity are crucial.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||