SANY 13697242 SY700/SY750 Track Sprocket/Drive Wheel AS/Heavy duty Chassis Components source manufacturer and Supplier-dpwparts

Product Specifications

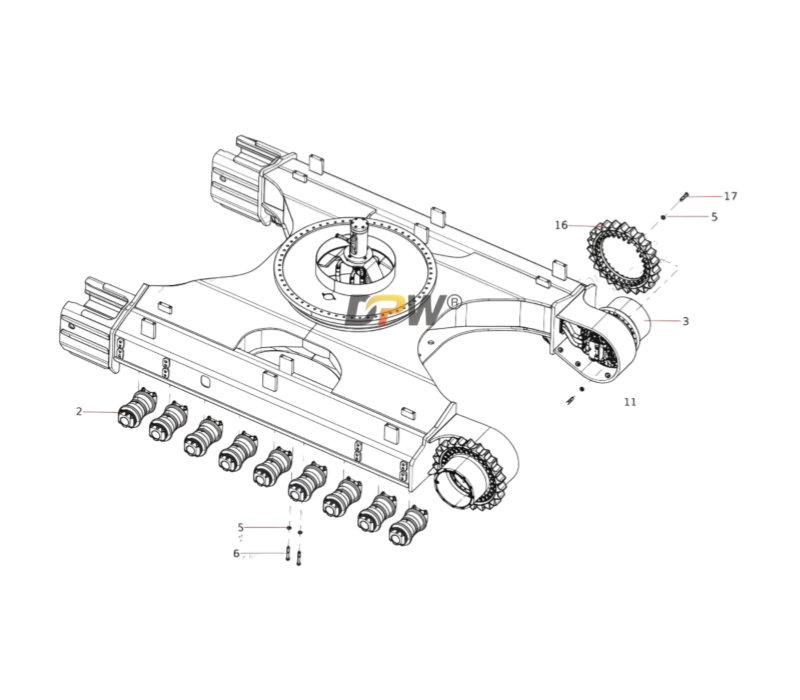

Technical Description: SANY 13697242 SY700/SY750 Track Sprocket/Final Drive Wheel Assembly

1. General Overview & Functional Definition

The SANY 13697242 Track Sprocket/Final Drive Wheel Assembly is the definitive, integrated power-output component for the track propulsion system of the SANY SY700 and SY750 hydraulic excavators. This assembly represents a complete "power-at-the-wheel" solution, combining the final gear reduction stage with the drive sprocket into a single, robust unit. Its primary functions are:

Final Reduction & Torque Multiplication: It houses a multi-stage planetary gear reduction system that dramatically increases the output torque from the high-speed hydraulic travel motor, converting it into usable propulsive force.

Traction Generation: The sprocket teeth directly mesh with and pull the track chain bushings, generating the forward and reverse motion of the machine.

Structural Anchor Point: It serves as a critical structural element of the undercarriage, reacting against the immense forces generated by drive torque, track tension, and the machine's weight.

Sealed and Lubricated System: It provides a sealed, oil-bath environment for the high-speed gears and bearings, ensuring efficient operation, heat dissipation, and maximum protection from external contaminants.

2. Detailed Component Breakdown & Technical Specifications

This assembly, identified by the OEM part number 13697242, is a pre-assembled and tested unit designed for maximum durability in the 70-75 ton excavator class.

2.1. Sprocket Wheel (Drive Rim)

Material & Manufacturing: Forged from a high-carbon, high-manganese alloy steel (e.g., 50Mn or 42CrMo) to provide an optimal balance of extreme strength, impact toughness, and wear resistance. The forging process ensures a superior grain structure that is essential for handling shock loads.

Design Features:

Precision Tooth Profile: The teeth are machined to an exact pressure angle and pitch to ensure perfect, non-slip engagement with the track chain bushings. This precise meshing is critical for efficient power transfer and minimizing premature wear.

Advanced Surface Hardening: The entire tooth profile, including the flanks and critical root area, undergoes induction hardening or flame hardening. This creates a deep, durable hardened case (typically 7-10 mm) with a surface hardness of 58-63 HRC, engineered to withstand severe abrasive wear.

Integrated Mounting: The sprocket is directly splined or bolted to the output planetary carrier, creating a solid, non-slip connection for transmitting the full drive torque.

2.2. Final Drive Gearbox

Planetary Gear Set: The heart of the assembly, utilizing two or three stages of planetary reduction. This compact, coaxial design efficiently achieves a high reduction ratio while distributing loads evenly across multiple planet gears, minimizing individual component stress.

Components: Includes a sun gear (input), planet gears, planet carriers, and a stationary ring gear housed within the main casing.

Final Drive Housing: A high-strength, rigid cast steel housing that encloses the entire gear train. Its structural integrity is vital for maintaining gear alignment under full load and providing a secure mounting point to the track frame.

Input Hub: The splined or keyed interface that connects directly to the output shaft of the hydraulic travel motor.

2.3. Bearing System

Configuration: Employs a combination of Large-Diameter Tapered Roller Bearings and Cylindrical Roller Bearings.

Function:

Tapered Roller Bearings: Specifically selected to handle the combined immense radial loads from the machine's weight and the substantial axial (thrust) loads generated during turning and from track tension.

High Dynamic Load Capacity: All bearings are rated for ultra-high dynamic loads to ensure longevity and reliability under continuous severe-duty operation.

2.4. Multi-Stage Sealing System

Configuration: A critical, multi-barrier system is employed to protect the internal components. SANY typically uses a Floating Face Seal (similar to a Duo-Cone seal) or a heavy-duty radial lip seal as the primary defense.

Primary Dynamic Seal: Located between the rotating sprocket and the stationary housing, this seal is designed to exclude fine, abrasive particles and water, even under shaft deflection.

Labyrinth and Scraper Pre-Seals: External labyrinth paths and rubber scraper rings work together to keep larger debris, mud, and rocks away from the primary seal.

Input Shaft Seal: A separate seal prevents oil leakage at the interface with the travel motor.

Breather: A pressure-equalizing breather prevents seal damage from internal pressure buildup due to thermal expansion.

2.5. Lubrication System

The gearbox is filled with a specific type and volume of Extreme Pressure (EP) Hypoid Gear Oil (e.g., API GL-5). This oil lubricates the gears and bearings, carries away heat, and provides protection against wear, rust, and foaming.

3. Integration within the SY700/SY750 Undercarriage System

The Final Drive Sprocket Assembly is the terminus of the machine's propulsion system:

Interface with Hydraulic System: It is bolted directly to the SANY Travel Motor.

Interface with Track Frame: It is flange-mounted to the rear of the Track Roller Frame, forming a rigid structural component.

Interface with Track Chain: It drives the Track Chain by meshing with the track bushings, working in concert with the Front Idler and Rollers to create a continuous track loop.

4. Critical Performance & Maintenance Parameters

Matched-Wear Principle (Critical): The sprocket and track chain are designed to wear together. Installing a new sprocket on a severely worn chain (or vice versa) will cause accelerated, destructive wear due to pitch mismatch, leading to rapid failure of both components.

Sprocket Wear Monitoring: Regularly inspect the sprocket teeth for wear. A "hooked" or sharply pointed profile indicates excessive wear and necessitates replacement to prevent jumping the track and damaging the chain.

Oil Analysis and Level Checks: Periodic oil sampling and analysis can detect early signs of internal wear (metal particles) or contamination (water, dust). Maintaining the correct oil level is essential to prevent catastrophic failure.

Seal Integrity: Regular visual inspection for oil leaks around the sprocket hub and input shaft is crucial. A leaking main seal will lead to rapid loss of lubrication and ingress of contaminants.

5. Failure Mode and Effects Analysis (FMEA)

Accelerated/Uneven Tooth Wear: Caused by mismatched track chain, improper track tension, or an misaligned undercarriage.

Tooth Chipping or Fracture: Resulting from extreme impact loads or material fatigue.

Bearing Spalling or Seizure: Often a consequence of seal failure, lubricant loss, or contamination ingress.

Gear Pitting/Spalling: A surface fatigue failure due to repeated high-contact stresses over time.

Input Shaft Seal Failure: Leads to oil loss and contamination of the final drive internals.