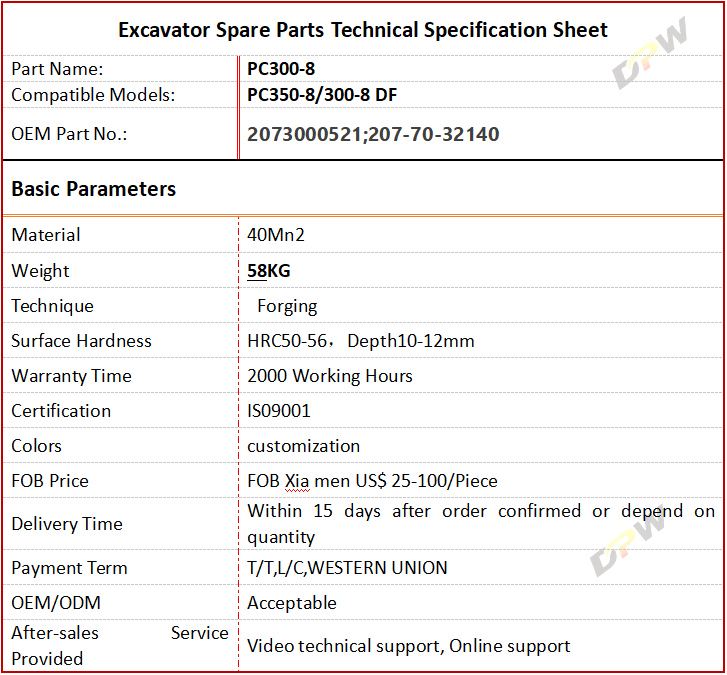

NEW KOMATSU PC350-DF track roller ass'y(2073000521;207-70-32140)Custom Tracked Chassis and Chassis Components Manufacturing Factory/track roller manufactures in china.

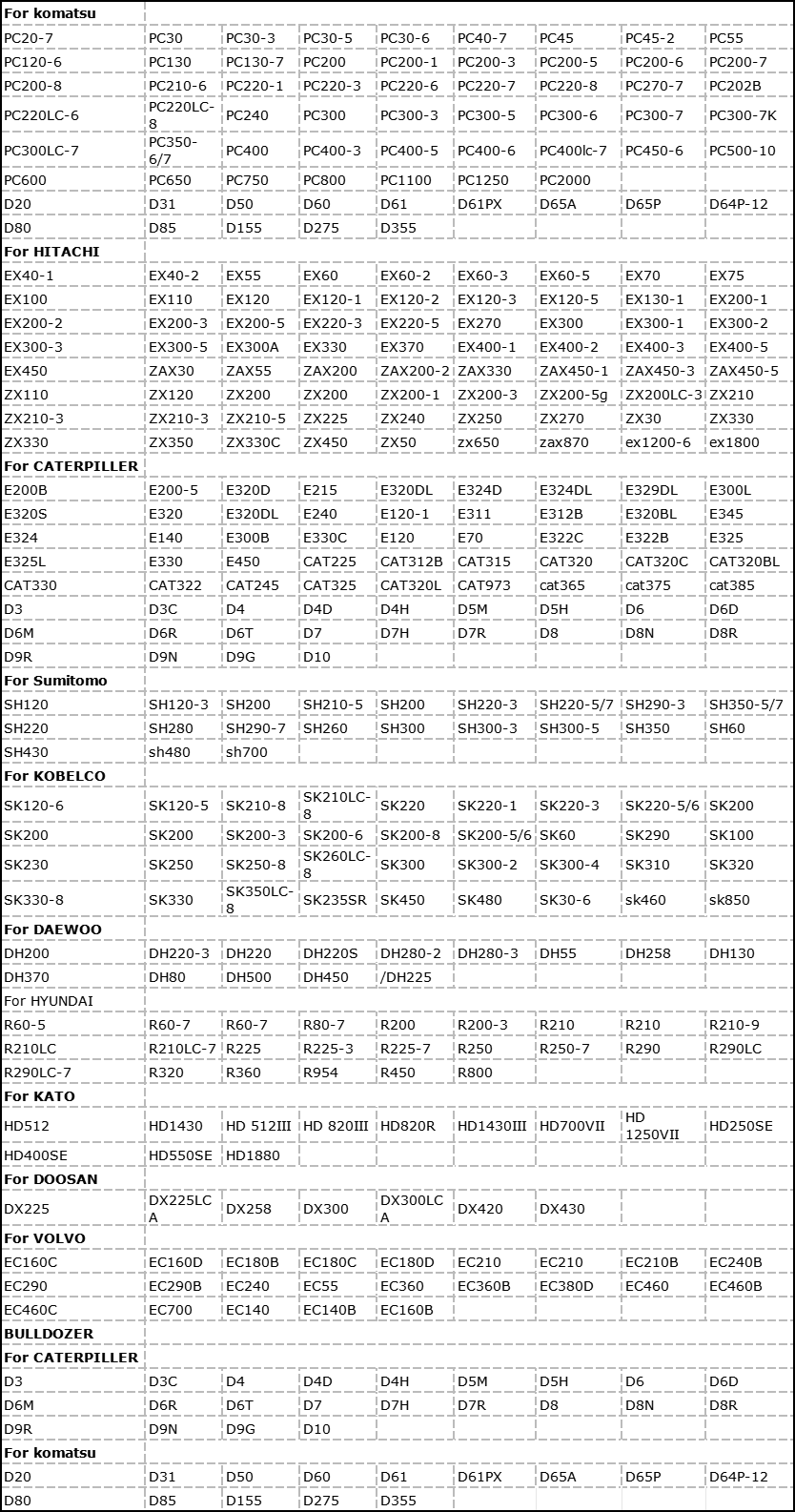

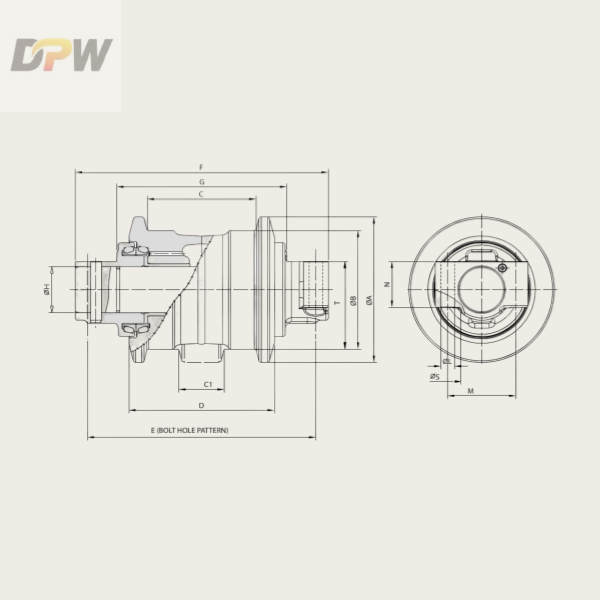

Product Specifications

DPW-PARTS factory specializes in the design, engineering, and production of custom tracked chassis and chassis components for a wide range of industrial, military, agricultural, and off-road applications. We provide tailor-made solutions to meet specific performance, durability, and terrain adaptability requirements.

Our Capabilities

1. Custom Tracked Chassis Manufacturing

Applications:

Military & defense vehicles

Construction & mining equipment

Agricultural machinery

Snow & swamp vehicles

Robotics & autonomous platforms

Design Features:

High-strength steel or aluminum alloy construction

Modular design for easy maintenance & upgrades

Optimized weight distribution for stability

Custom track width & length for specific terrains

Integrated suspension systems (torsion bars, hydro-pneumatic)

2. Chassis Components & Accessories

We produce high-precision chassis parts, including:

Track systems: Rubber, steel, or hybrid tracks

Sprockets, idlers & rollers (hardened for wear resistance)

Bogies & suspension arms

Frame reinforcements & mounting brackets

Hydraulic & electrical integration points

Manufacturing Process

Engineering & Prototyping

CAD/CAE design & simulation (stress, fatigue analysis)

3D printing & CNC prototyping for validation

Material Selection

High-tensile steel, aluminum alloys, or composite materials

Anti-corrosion treatments (galvanization, powder coating)

Production

Laser cutting, CNC machining, welding (MIG/TIG)

Precision casting & forging for high-load components

Testing & QA

Hardness testing, load testing, dynamic stress tests

Real-world terrain trials

Why Choose Us?

✔ Custom Solutions – Tailored to your exact specs (dimensions, load capacity, terrain)

✔ High Durability – Military-grade materials & rigorous testing

✔ Fast Turnaround – From design to delivery

✔ OEM/ODM Support – Work with your engineering team-DPW-parts