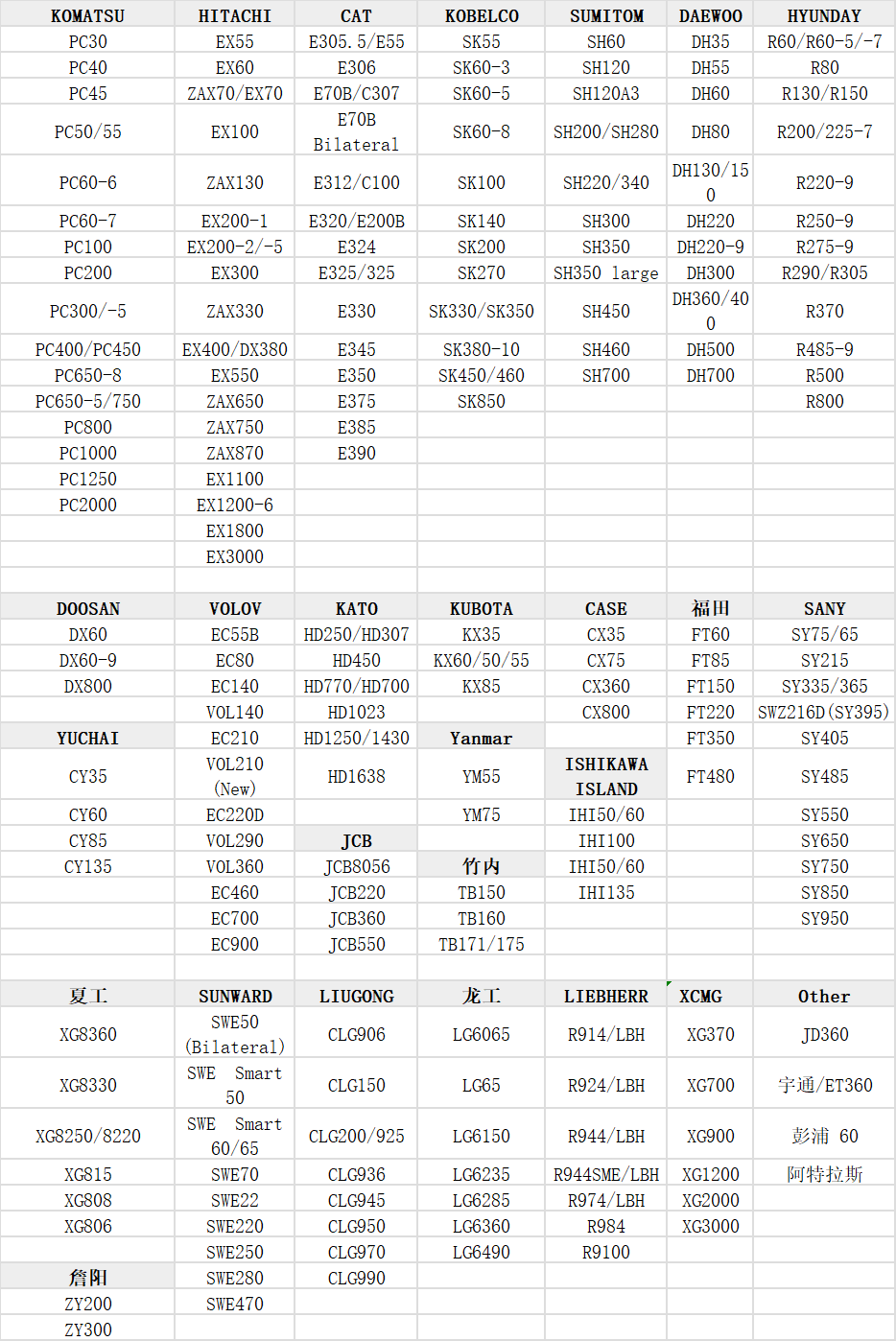

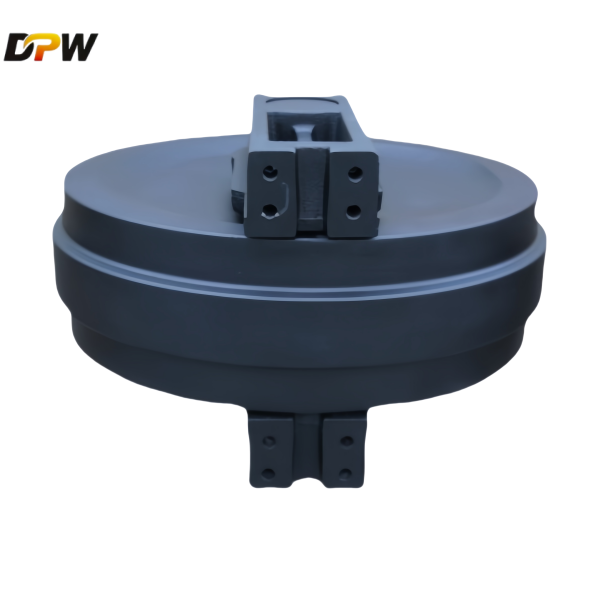

LIEBHERR-R974- front idler(P/N:5000127,5601867,7490851)China under carriage parts manufacture/idler factory/guide wheel customization

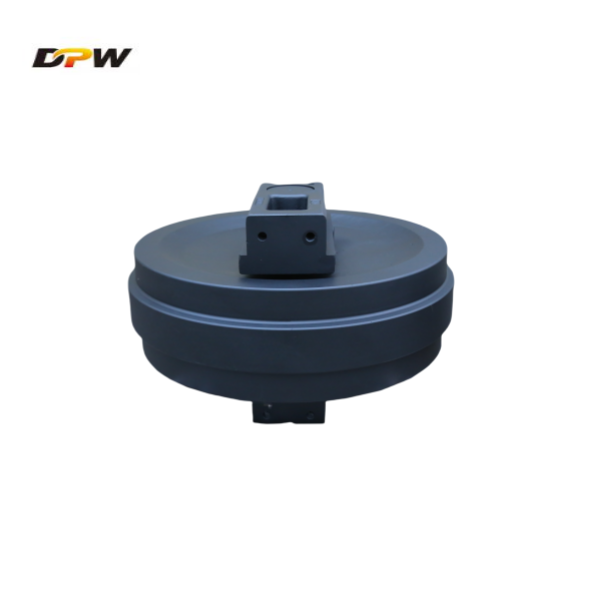

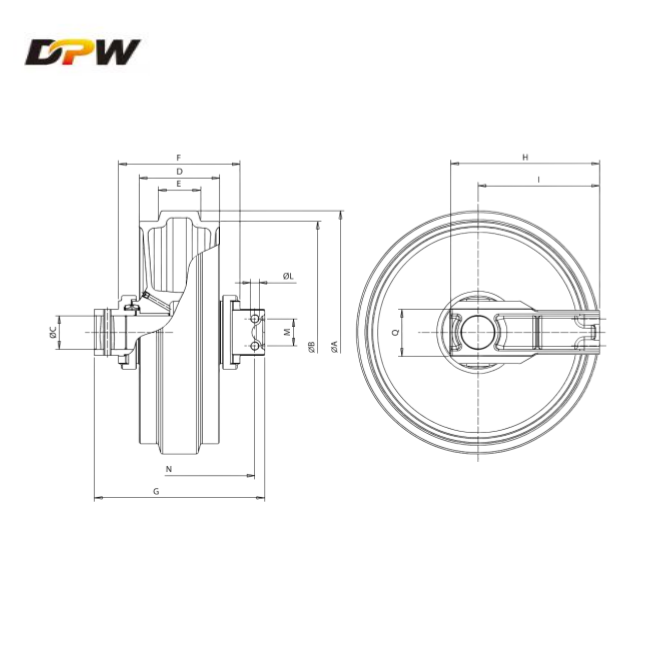

Product Specifications

LIEBHERR-R974 Front Idler Assembly(P/N:5000127,5601867,7490851)China undercarriage parts manufacture/idler factory/guide wheel customization

Liebherr 974 Idler Specifications

Type: Front idler (track tensioning)

Material: Forged steel with hardened wearing surfaces

Bearing Type: Sealed roller bearings (grease-lubricated)

Mounting Type: Adjustable for track tensioning

Weight: Approximately 150-200 kg (varies by model)

Common Part Numbers

(Always verify with your machine serial number)

Complete Idler Assembly:

Liebherr P/N: LH544 ,41408940,950371,5000127,561876,7365656,7490851,1416646

Aftermarket equivalents available

Idler Components:

Bearings: 22320 CC/W33 (common size - verify)

Seals: TC 80x110x12 (example)

Where to Get Technical Drawings

Liebherr Parts Portal (https://parts.liebherr.com)

Enter your machine serial number

Navigate to "Undercarriage" > "Idler" section

Liebherr Dealer Support

Contact your local Liebherr dealer with your serial number

Request "exploded view diagram" of idler assembly

Aftermarket Options

Quality Aftermarket Suppliers:

www.cqctrack.com

Considerations When Buying Aftermarket:

Verify exact dimensions match OEM

Check bearing specifications

Confirm steel hardness ratings

Maintenance Tips

Regular Inspection:

Check for cracks or worn flanges

Monitor bearing play (should be < 2mm radial movement)

Look for grease leaks

Proper Adjustment:

Maintain correct track tension (typically 1-1.5" sag at mid-span)

Follow Liebherr's tensioning procedure

Lubrication:

Use high-quality lithium complex grease

Grease every 50-100 operating hours

Troubleshooting Common Issues

| Symptom | Possible Cause | Solution |

|---|---|---|

| Excessive track sag | Worn idler bushings | Replace idler assembly |

| Track running off | Misaligned idler | Adjust alignment |

| Grinding noise | Failed bearings | Replace bearings/seals |

| Grease leakage | Damaged seals | Rebuild or replace idler |