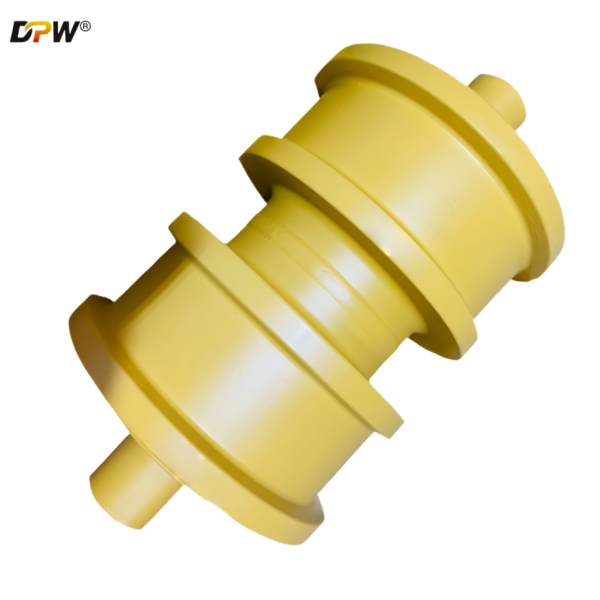

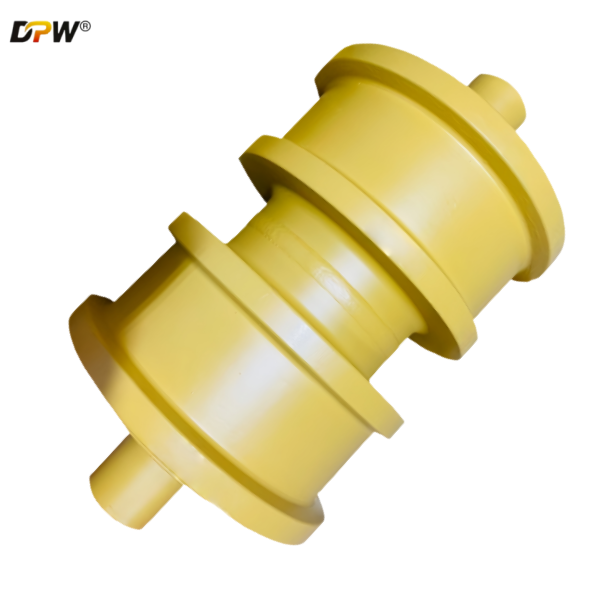

Undercarriage of Komatsu/1953001465/1953007221/D375/SD52/SD60-DF/SF Track Roller Assembly

Product Specifications

Komatsu D375/DF Track Roller Assembly: A Comprehensive Overview

DPW PARTS' Track Roller Assembly is a critical component within the undercarriage system of the Komatsu D375/DF super large bulldozer. Its primary function is to support the weight of the machine, guide the track chain, and maintain track alignment and tension during operation. The durability and performance of these assemblies directly impact the machine's stability, traction, efficiency, and overall undercarriage life.

1. Machine Context: Komatsu D375/DF Bulldozer

Model: The Komatsu D375A is a later model in the D375 series, with the "DF" suffix typically denoting a specific configuration or market variant (e.g., Deep Forest or a specific emissions standard package). These are massive, high-horsepower bulldozers designed for the most demanding applications, such as large-scale mining, quarrying, and major earthmoving projects.

Importance of Undercarriage: Given the immense weight and power of the D375 (operating weights exceeding 70 tons), its undercarriage is subjected to extreme stresses, abrasion, and impact loads. Every component, especially the track rollers, must be built to exceptional standards of strength and durability.

2. Function and Role of the Track Roller Assembly

The track roller assembly is not a single part but a system of components that performs several vital functions:

Weight Support: The rollers bear a significant portion of the machine's immense weight, transferring it through the track chain and onto the ground.

Track Guidance: They guide the upper section of the track chain (the "return" strand) along a precise path, preventing lateral sway and ensuring proper engagement with the sprocket and idler.

Track Tension Maintenance: By providing a defined path, they help maintain consistent track tension, which is crucial for efficient power transfer and preventing derailment.

Reduction of Friction and Wear: They minimize direct sliding contact between the track chain links and the mainframe of the bulldozer, reducing friction, energy loss, and wear on both the chain and the frame.

3. Detailed Components of the Assembly

A complete track roller assembly for a machine like the D375/DF typically consists of the following key parts:

a) Track Roller (or Carrier Roller)

Description: This is the main cylindrical component that physically contacts the track chain. It is a heavily built, sealed, and lubricated assembly.

Construction: The outer shell is made from extremely high-strength, hardened alloy steel to resist grinding abrasion from track chain contact. The interior contains a robust bearing system.

Sealing: Utilizes Komatsu's advanced multi-lip seals to create a permanent barrier against contaminants (dust, mud, water) and to retain lubricating grease inside. This is critical for longevity in harsh environments.

Lubrication: Pre-packed with special high-temperature, high-pressure grease during manufacturing. It is designed to be "lubricated-for-life," meaning it does not require routine maintenance greasing.

b) Track Roller Frame (or Bracket)

Description: The forged or cast structural bracket that connects the track roller to the main bulldozer frame (the track roller frame).

Function: It provides a rigid and secure mounting point, ensuring the roller is correctly positioned and aligned.

c) Bolts, Nuts, and Hardware

Description: High-strength, precision-fit bolts and nuts used to secure the roller frame to the main undercarriage.

Importance: These are critical fasteners. They are designed to withstand immense shear and tensile forces. They must be torqued to Komatsu's exact specifications using proper procedures to prevent catastrophic failure.

d) Flange (if applicable)

Description: Some roller designs may incorporate a flange on one or both sides.

Function: The flange acts as a physical guide to keep the track chain centered on the roller, preventing it from slipping off sideways.

e) Bushing and Pin (Internal Components)

Description: Inside the roller itself, a hardened steel pin acts as the axle. This pin rotates within a hardened and precisely machined bushing. Needle or roller bearings are often used between the pin and the bushing to facilitate smooth rotation with minimal friction.

4. Material and Engineering Specifications

Metallurgy: Components are fabricated from specialized, tough alloy steels (e.g., SCr, SCM series). Critical wear surfaces undergo heat treatment processes like induction hardening or carburizing to create an incredibly hard, wear-resistant outer layer while maintaining a tough, shock-absorbing core.

Sealing Technology: Komatsu uses proprietary seal designs (often a combination of radial and face seals) with special synthetic rubber compounds that remain flexible in extreme temperatures and resistant to oils and chemicals.

Precision Machining: All components are machined to extremely tight tolerances to ensure perfect alignment, which is essential for distributing load evenly and maximizing service life.

5. Common Failure Modes and Causes

Normal Wear: The outer diameter of the roller gradually wears down from constant friction with the track chain.

Flange Wear: The guiding flanges can wear thin or break off due to lateral forces from the track.

Seal Failure: The most common cause of premature roller failure. If the main seal is damaged (e.g., by a rock, stick, or improper handling), contaminants enter the assembly, acting as an abrasive paste that quickly destroys the internal bearings and wears out the pin and bushing. This leads to:

Loss of Lubrication: Grease leaks out.

Noisy Operation: Grinding or squealing sounds.

Seized Roller: The roller stops turning, causing rapid, accelerated wear on the track chain links themselves.

Bearing Failure: Internal bearings can spall, brinell, or fracture due to shock loads or contamination.

Structural Damage: The roller or its frame can be cracked or broken by severe impact with large rocks or other obstacles.

6. Maintenance and Replacement Considerations

Inspection: Regular visual inspection is crucial. Look for:

Wear: Measuring roller diameter against Komatsu's wear limits.

Leaks: Signs of grease leaking from the seals.

Rotation: Ensure all rollers are turning freely. A stationary roller is a sign of failure.

Damage: Cracks, broken flanges, or deep gouges.

Replacement: Track rollers are typically replaced as a complete assembly unit. Due to their size, weight, and the forces involved, replacement requires heavy-duty equipment (jacks, cranes) and must be performed by trained technicians following Komatsu safety and service procedures.

Matching Undercarriage Wear: It is often recommended to replace undercarriage components in sets (e.g., all track rollers, or rollers along with the track chain and sprockets) to ensure even wear patterns and prevent accelerated wear on new components matched with severely worn ones.

7. Part Numbering and Sourcing

Genuine Komatsu Parts: Komatsu parts are identified by a unique Part Number (195-30-07221/195-30-01465)– this is an example; the exact number for a specific D375/DF variant must be confirmed). Using genuine parts guarantees perfect fit, performance, and durability, as they are engineered to exact OEM specifications.

Aftermarket Alternatives: Various aftermarket manufacturers offer replacement rollers. These can range from high-quality, certified equivalents to lower-quality options. Key factors to consider are material quality, seal technology, and warranty.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||