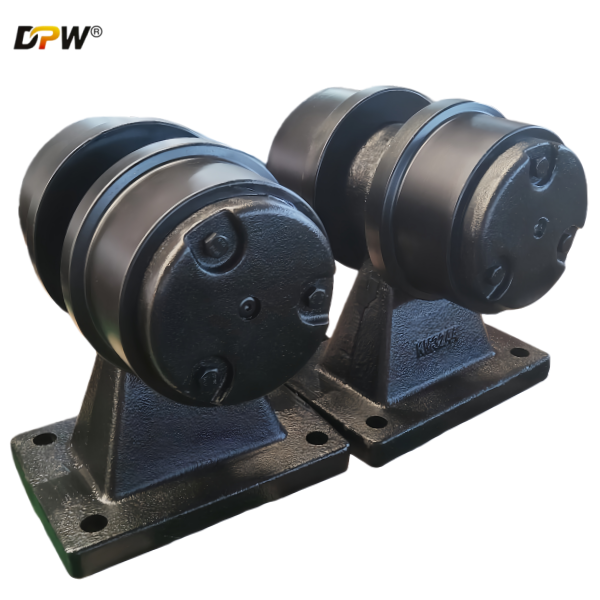

Komatsu KM3244/2093000300 PC750/PC800 Carrier Roller Assy/Upper Roller Group/Heavy duty Undercarriage System expert/manufacturer-DPW Parts

Product Specifications

Technical Data Sheet: Carrier Roller / Upper Roller Assembly

Part Identification:

Komatsu Part Number: KM3244/209-30-00300

Compatible Machine Models: Komatsu PC750, PC800 Series Hydraulic Excavators.

Application: Undercarriage System.

Component Aliases: Carrier Roller, Upper Roller, Top Roller.

1.0 Component Overview

The Part Number KM3244/2093000300 is a Carrier Roller Assembly, also universally known as an Upper Roller. This component is a vital part of the excavator's undercarriage system, positioned at the top of the undercarriage frame. Its primary role is not to support the machine's weight, but to maintain the correct alignment and tension of the track chain's upper strand (the return side) as it travels between the front idler and the rear sprocket.

2.0 Primary Function & Operational Context

The core functions of this assembly are:

Track Guidance and Alignment: It guides the upper section of the track chain, preventing lateral whip and ensuring it remains centered and properly aligned as it returns to the sprocket. This is crucial for stable travel and preventing derailment.

Track Sag Management (Tension Control): It maintains the proper amount of track sag, which is essential for effective track tension. Correct tension minimizes rolling resistance, reduces wear on all undercarriage components, and ensures optimal power transfer from the sprocket to the ground.

Debris Shedding: As the track chain passes over the roller, the rotation helps to shed mud, clay, and other debris that may be packed into the track links, contributing to self-cleaning.

3.0 Detailed Construction & Key Sub-Components

A Carrier Roller Assembly is a complex, sealed mechanism comprising:

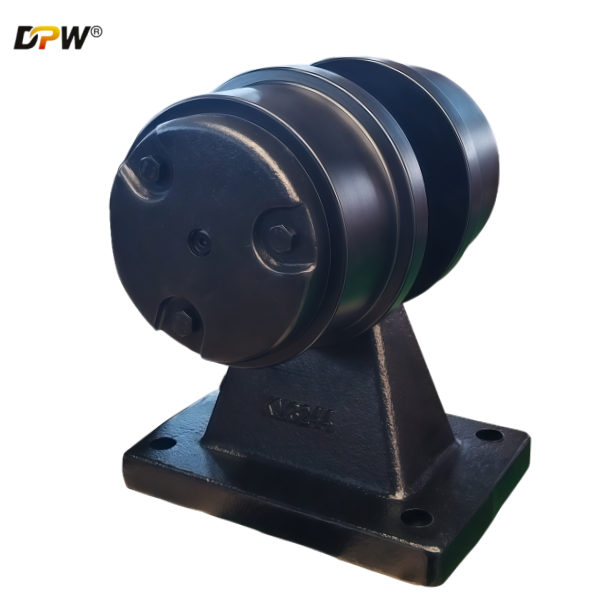

3.1 Outer Rim / Tread: The smooth, hardened cylindrical surface that makes direct contact with the track chain links. Unlike a sprocket, it has no teeth.

3.2 Flanges: Prominent lateral guides on one or both sides of the tread. These flanges are critical for preventing the track chain from sliding off the roller during side-loading operations such as turning or working on slopes.

3.3 Shaft: A hardened and precision-ground steel shaft that is pressed and secured into the roller's mounting bracket. This shaft remains stationary.

3.4 Bushing & Bearing System: The roller housing rotates around the stationary shaft via a set of heavy-duty tapered roller bearings or a bronze bushing. These components are designed to handle moderate radial loads and continuous rotation.

3.5 Sealing System: A multi-layered, labyrinth-style seal is the most critical component for longevity. It typically consists of a primary face seal, an outer dust lip, and often an O-ring. This system is tasked with excluding abrasive contaminants (dirt, sand, water) and retaining the high-performance grease within the bearing cavity. The effectiveness of this seal directly determines the service life of the entire assembly.

3.6 Housing and Mounting Bracket: The main body that houses the internal components and provides the attachment points (e.g., bolt holes or a specific profile) to the undercarriage frame.

4.0 Material & Performance Specifications

Material: High-Carbon or Alloy Steel Casting/Forging.

Hardness: The tread and flange contact surfaces are through-hardened or induction-hardened to a typical hardness of 55-60 HRC to resist abrasive wear from the track chain.

Lubrication: Pre-filled with a high-temperature, extreme-pressure (EP) lithium-complex grease. Most modern carriers are equipped with a grease fitting (zerk) for periodic re-lubrication during service intervals to purge contaminants and extend life.

5.0 Failure Modes & Maintenance Considerations

Wear Limits: Serviceability is determined by measuring the reduction in flange height and tread diameter against Komatsu's specified wear limits. Worn flanges increase the risk of track derailment.

Common Failure Modes:

Flange Wear: The flanges wear down on their inner sides due to constant contact with the track chain guides.

Tread Wear: The smooth tread surface can develop a concave wear pattern from friction with the track links.

Bearing/Bushing Failure: Seizure or excessive play caused by seal failure, leading to contamination of the lubricant and accelerated wear. This often manifests as a roller that does not turn freely or has noticeable vertical play.

Seal Failure: The primary cause of premature roller failure, allowing abrasive particles to enter and destroy the bearing surfaces.

Maintenance Practice: Regular inspection for rotation (should spin freely but not wobble) and visual checks for grease leakage or damage are essential. Carrier rollers should be replaced in pairs (on the same side of the machine) and their condition should be evaluated alongside the entire undercarriage system (sprockets, track chains, idlers, bottom rollers) for a coherent maintenance strategy.