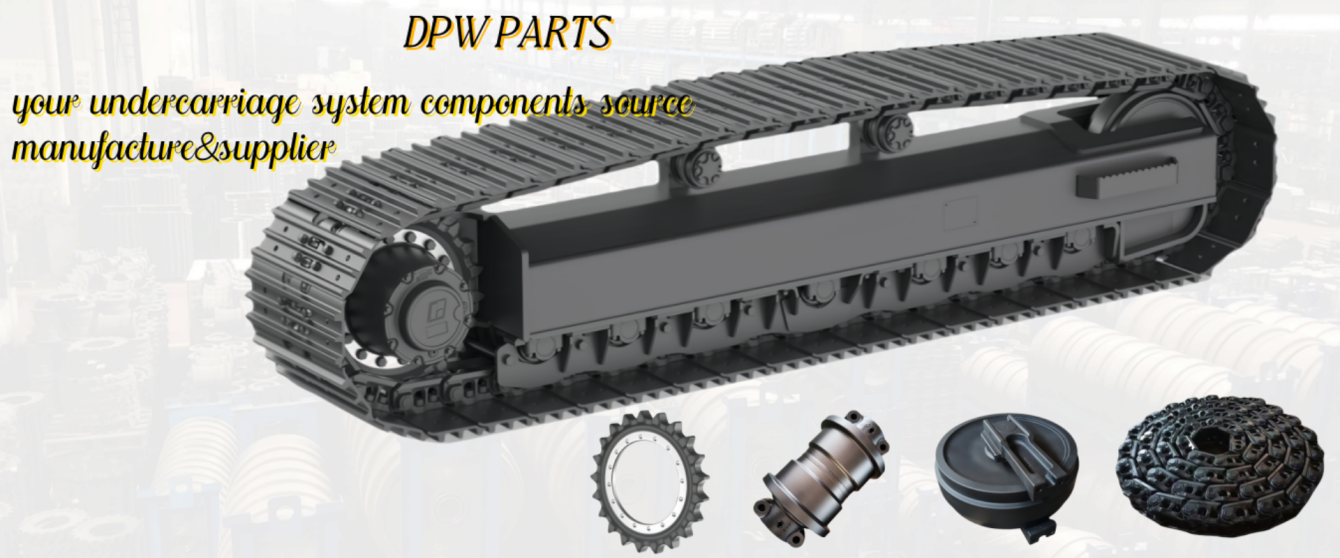

INGERSOLL RAND/SANDVICK/5780322/D45KS D50KS D75KS/Atlas Copco 57717498 Drilling Rig Undercarriage components manufacture and source factory

Product Specifications

DPW PARTS' Fabricated Front Idler Assembly for the D45KS drill rig exemplifies heavy-duty engineering, combining welded steel robustness with precision machining and sealing technology. Designed for compatibility across Ingersoll Rand, Sandvik, and Atlas Copco platforms, it ensures reliability, durability, and peak performance in the most demanding drilling environments.

Product Overview

The Fabricated Front Idler Assembly is a critical component of the undercarriage system on the Ingersoll Rand/Sandvik/Atlas Copco D45KS drill rig. Designed to guide and tension the track chain, this idler ensures stable movement, absorbs shock loads, and maintains track alignment on rugged terrain. Its fabricated (welded) construction provides superior strength-to-weight ratio and impact resistance, making it ideal for heavy-duty drilling and mining operations.

Key Features & Technical Specifications

Compatibility

OEM replacement part for Ingersoll Rand D45KS, Sandvik D45KS, and Atlas Copco D45KS drill rigs.

Construction

Fabricated Steel Design: Welded from high-strength, abrasion-resistant steel plates (e.g., Hardox® 400 or equivalent) for enhanced durability and crack resistance.

Induction-Hardened Flanges: Surface hardness of 55-60 HRC to withstand abrasive wear from track chain contact.

Machined Bore & Shaft Interfaces: Precision-machined for seamless integration with the track frame and tensioning system.

Bearing & Sealing System

Tapered Roller Bearings: Heavy-duty bearings capable of handling radial and axial loads under extreme shock and vibration.

Multi-Lip Labyrinth Seals: Advanced sealing technology to exclude contaminants (e.g., rock dust, slurry) and retain lubrication.

Lube-for-Life Design: Pre-lubricated and sealed at the factory, eliminating routine maintenance.

Functionality

Track Guidance: Dual flanges prevent lateral derailment during operation on uneven surfaces.

Tensioning Pivot: Integrates with the hydraulic track tensioning system to adjust track sag.

Impact Resistance: Dissipates shock loads from obstacles and rough terrain.

Durability Enhancements

Stress-relieved welds to prevent fatigue cracking.

Corrosion-resistant primer and paint coating on non-wear surfaces.

Applications

Surface Mining: Drill rig mobility on rocky and abrasive terrain.

Quarry Operations: Navigating uneven surfaces with heavy loads.

Construction and Civil Engineering: Precision drilling and tracking on challenging sites.

Benefits of OEM-Quality Replacement

Extended Service Life: Fabricated construction and hardened flanges reduce wear rates.

Reduced Downtime: Precision fit ensures easy installation and reliable performance.

Contamination Resistance: Advanced seals protect bearings from harsh environments.

Cost Efficiency: Promotes balanced undercarriage wear, protecting track chains and sprockets.

Maintenance Recommendations

Regular Inspection: Check for flange wear, seal integrity, and rotational freedom during routine servicing.

Track Tension Adjustment: Follow OEM guidelines to maintain optimal track sag and prevent idler overload.

Debris Cleanliness: Remove packed material around the idler to reduce seal abrasion.

Conclusion

The Fabricated Front Idler Assembly for the D45KS drilling rig exemplifies heavy-duty engineering, combining welded steel robustness with precision machining and sealing technology. Designed for compatibility across Ingersoll Rand, Sandvik, and Atlas Copco platforms, it ensures reliability, durability, and peak performance in the most demanding drilling environments.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||