Hitachi YA00001980 ZX900-6A/ZX890-5A Final Drive Sprocket Assembly/heavy duty crawler excavator undercarriage parts manufacturer and supplier

Product Specifications

Technical Overview: Hitachi ZX900-6A Final Drive Sprocket Assembly

The Final Drive Sprocket Assembly for the Hitachi ZX900-6A hydraulic excavator is a mission-critical, high-stress component within the machine's undercarriage system. It functions as the primary interface that translates the high-torque, low-speed rotational output of the final drive into linear track movement, enabling the propulsion of this 90-ton class machine across demanding worksites.

This assembly is engineered for maximum durability, power transmission efficiency, and resistance to extreme shock loads and abrasive wear.

1. Functional Definition and Operational Role

The Sprocket Assembly serves two interconnected primary functions:

Power Transmission: It acts as the final gear in the power train, directly engaging with the track chain's bushings (the "pins and bushings"). The teeth of the sprocket mesh with the gap between the track chain bushings, pulling the track around the idlers and rollers.

Load Bearing: The assembly bears the entire weight of the machine transmitted through the track chain, in addition to承受ing severe operational loads from digging, lifting, and traversing uneven terrain. It is subjected to a combination of tensile, compressive, and shear stresses.

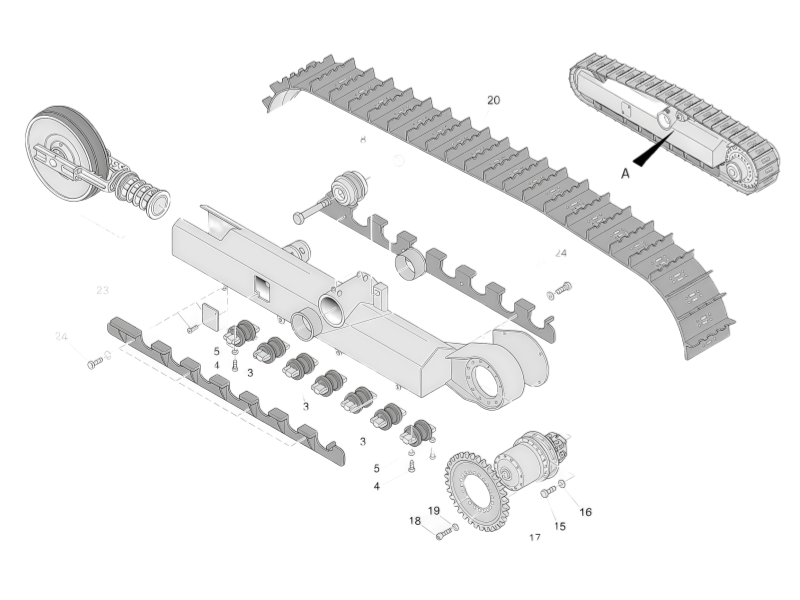

2. Detailed Component Breakdown

While often referred to as a single unit, the assembly comprises several key integrated components:

A. Sprocket Wheel (The Toothed Ring):

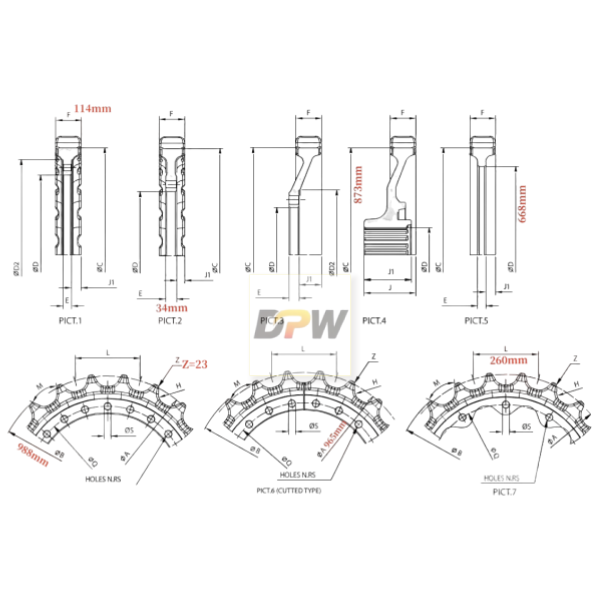

Material: Fabricated from high-carbon, high-alloy steel (e.g., 4140 or similar) forgings for superior grain structure and impact strength.

Heat Treatment: Undergoes a controlled hardening process, such as induction hardening or flame hardening, specifically applied to the tooth profiles and roots. This creates an extremely hard, wear-resistant surface (typically 55-60 HRC) while maintaining a tougher, more ductile core to prevent catastrophic fracture.

Tooth Profile: The tooth geometry is precision-machined to ensure smooth engagement and disengagement with the track chain bushings, minimizing impact and reducing noise. The tooth count for the ZX900-6A is typically 21 teeth.

B. Hub/Rim Assembly:

Construction: A robust, flanged disc, integrally cast or forged with the sprocket.

Mounting Flange: Features a precisely machined bolt circle pattern that aligns perfectly with the final drive's output hub. This flange is drilled and tapped to accommodate high-strength mounting bolts.

Sealing Surface: The inner bore is machined to a fine finish to ensure a proper seal with the final drive's face, protecting the internal components from contaminants.

C. Mounting Hardware:

Bolts: High-grade, metric property class 10.9 or 12.9 cap screws are used.

Locking Mechanism: Often incorporates serrated flange nuts, thread-locking fluid, or dowel pins to prevent loosening under intense vibration and cyclic loading.

3. Key Technical Specifications for Hitachi ZX900-6A

Parameter Specification Notes Compatible Machine Model Hitachi ZX900-6A Must specify the dash number (-6A) for correct fitment. Common OEM Part Number YA00001980 Always verify using the machine's Serial Number (S/N). Tooth Count 21 Teeth Matches the track chain pitch for correct engagement. Mounting Bolt Pattern Specific to ZX900-6A Final Drive Typically a multi-bolt (e.g., 12 or 14) circular pattern. Weight Several Hundred Kilograms Requires appropriate lifting equipment for handling.

| Parameter | Specification | Notes |

|---|---|---|

| Compatible Machine Model | Hitachi ZX900-6A | Must specify the dash number (-6A) for correct fitment. |

| Common OEM Part Number | YA00001980 | Always verify using the machine's Serial Number (S/N). |

| Tooth Count | 21 Teeth | Matches the track chain pitch for correct engagement. |

| Mounting Bolt Pattern | Specific to ZX900-6A Final Drive | Typically a multi-bolt (e.g., 12 or 14) circular pattern. |

| Weight | Several Hundred Kilograms | Requires appropriate lifting equipment for handling. |

4. Common Failure Modes and Root Cause Analysis

A. Normal Wear Progression:

Initial Stage: A slight curvature forms at the tip of the sprocket teeth.

Advanced Stage ("Hooking" or "Pointing"): The leading faces of the teeth wear down, creating a sharp, hooked profile. This reduces the contact area with the track bushing, leading to improper engagement, accelerated chain wear, and an increased risk of track derailment.

B. Abnormal Failures:

Premature Wear: Caused by operating with a severely worn track chain. A new sprocket paired with a worn chain will fail rapidly due to mismatched pitch.

Tooth Chipping or Fracture: Results from high-impact loads, material fatigue, or improper heat treatment.

Cracked Rim/Hub: Often due to excessive over-tightening of bolts, improper installation, or operating with loose bolts.

Elongated Bolt Holes: Caused by the assembly working loose, leading to fretting and wallowing out the mounting holes, which can damage the final drive itself.

A. Normal Wear Progression:

Initial Stage: A slight curvature forms at the tip of the sprocket teeth.

Advanced Stage ("Hooking" or "Pointing"): The leading faces of the teeth wear down, creating a sharp, hooked profile. This reduces the contact area with the track bushing, leading to improper engagement, accelerated chain wear, and an increased risk of track derailment.

B. Abnormal Failures:

Premature Wear: Caused by operating with a severely worn track chain. A new sprocket paired with a worn chain will fail rapidly due to mismatched pitch.

Tooth Chipping or Fracture: Results from high-impact loads, material fatigue, or improper heat treatment.

Cracked Rim/Hub: Often due to excessive over-tightening of bolts, improper installation, or operating with loose bolts.

Elongated Bolt Holes: Caused by the assembly working loose, leading to fretting and wallowing out the mounting holes, which can damage the final drive itself.

5. Sourcing and Replacement Protocol

OEM (Genuine Hitachi):

Advantage: Guaranteed fit, performance, and factory-grade material quality. Backed by a manufacturer's warranty.

Disadvantage: Premium cost.

Quality Aftermarket Equivalents:

Advantage: Significant cost savings. Reputable brands (DPW Parts) often use comparable materials and manufacturing processes.

Disadvantage: Requires due diligence to verify quality control and material specifications.

OEM (Genuine Hitachi):

Advantage: Guaranteed fit, performance, and factory-grade material quality. Backed by a manufacturer's warranty.

Disadvantage: Premium cost.

Quality Aftermarket Equivalents:

Advantage: Significant cost savings. Reputable brands (DPW Parts) often use comparable materials and manufacturing processes.

Disadvantage: Requires due diligence to verify quality control and material specifications.

Critical Replacement Procedure:

Undercarriage Audit: Never replace a sprocket in isolation. Measure the track chain (pitch, bushing diameter). The golden rule is "Never install a new sprocket on a worn-out chain." The mismatch in pitch will destroy the new sprocket in a very short time.

Contaminated Seal Prevention: During removal and installation, meticulously clean the final drive mounting surface to prevent dirt from entering the final drive seal, which would lead to its failure.

Precision Torquing: Mounting bolts must be tightened to the manufacturer's specified torque value in a star pattern sequence. The use of a calibrated torque wrench and a high-strength thread-locking compound is mandatory.

Post-Installation Check: After a short period of operation (e.g., 50 hours), re-check the bolt torque, as settlement and initial wear can cause them to loosen.

Common Applications:

Used in mining, quarrying, or heavy construction excavators.

Helps in easy replacement of worn-out undercarriage parts.

Manufacturers & Suppliers:

www.hangongmachinery.com

The Hitachi ZX900-6A Final Drive Sprocket Assembly is a precision-engineered component whose integrity is paramount to machine mobility, productivity, and operational safety. Adherence to proper inspection intervals, understanding failure modes, and following strict replacement protocols—including a comprehensive undercarriage assessment—are essential for maximizing component life and minimizing total cost of ownership for this high-value capital asset.