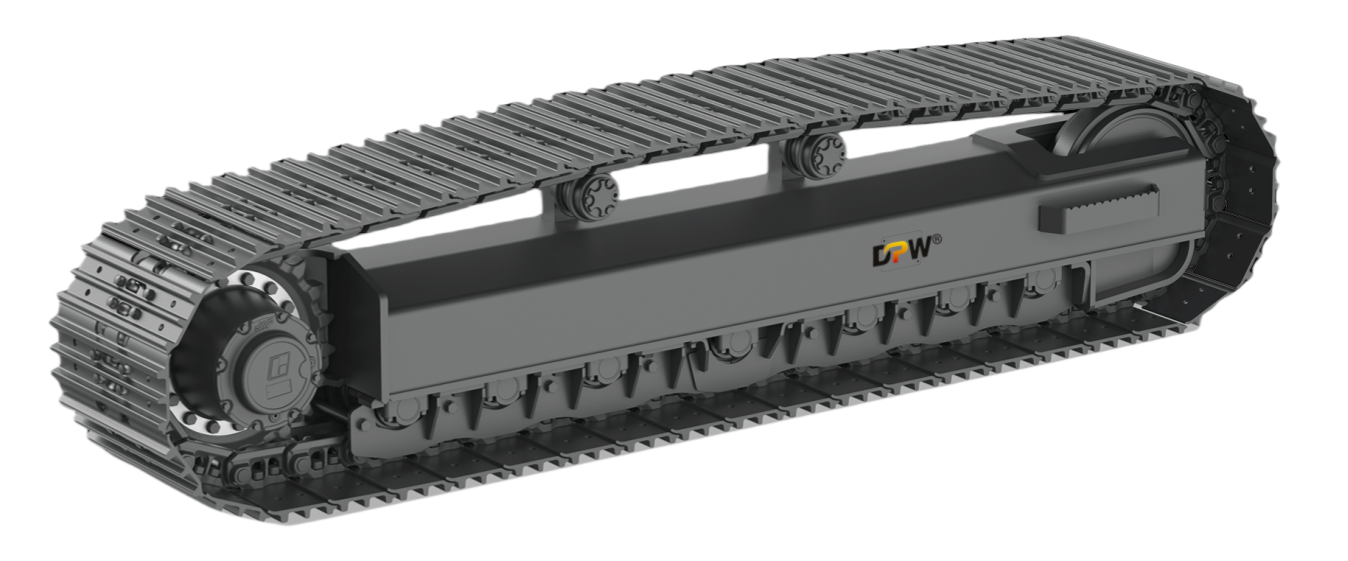

Heavy duty undercarriage of SDLG E6650 Track Bottom Roller Assembly

Product Specifications

DPW Machinery PARTS' Track Bottom Roller Assembly (also commonly referred to as the Lower Roller or Track Roller) is a fundamental component within the undercarriage system of the SDLG LG6650 excavator. The LG6650 is a 65-ton class excavator designed for demanding applications in construction, mining, quarrying, and heavy earthmoving.

Primary Functions:

Load Bearing: It is the primary component that supports the immense weight of the excavator. Multiple bottom rollers distribute the machine's operational weight evenly across the track chain and onto the ground.

Track Guidance: The roller features two integral flanges (rims) on its outer edges. These flanges guide the track chain, preventing lateral slippage and ensuring the track remains aligned on the undercarriage during operation, especially when turning or operating on slopes.

Facilitate Movement: The assembly contains a sealed bearing system that allows the roller to rotate smoothly and with minimal friction as the track chain is driven by the sprocket. This smooth rotation is critical for efficient power transmission and mobility.

A failure in a single bottom roller can have catastrophic cascading effects, leading to accelerated and uneven wear on the track chain (links, bushings, and pins), idlers, and sprockets. Ultimately, it can cause track derailment, resulting in significant downtime and expensive repairs.

2. Technical Specifications and Identification

Critical Note: Part numbers can vary based on the specific manufacturing series and serial number of the excavator. Always verify the exact part number using the machine's serial number with an authorized SDLG dealer or a reputable parts supplier.

OEM Part Number Examples:

Complete Assembly: A typical genuine SDLG part number might follow a format like E6650-5-12011 or LG6650-5-12011 (the specific digits will vary). This refers to the complete, ready-to-install unit.

Rebuild Kit: For workshop overhaul, a kit containing seals, bearings, O-rings, and sometimes the shaft might be numbered E6650-5-12012.

Dimensions (Approximate for a 50-ton class machine):

Overall Diameter: 220 mm - 240 mm

Tread Width: 140 mm - 150 mm

Flange Height: ~25 mm

Bolt Hole Circle (BHC): ~210 mm (This is the crucial measurement between the mounting bolt centers for fitment).

Mounting Bolt Size: Typically large high-strength bolts, often M20 x 2.5 or larger.

Construction & Design:

Material: The outer shell and flanges are manufactured from high-carbon, heat-treated alloy steel for exceptional hardness and abrasion resistance.

Sealing System: Utilizes a multi-layered, labyrinth-style seal (often a combination of radial lip seals and face seals) packed with special grease. This system is designed to keep contaminants (abrasive mud, sand, dust) out and retain lubricating grease in, even under high-pressure water wash-down conditions.

Internal Components: Contains precision tapered roller bearings or bushings designed to handle extreme radial loads.

3. Maintenance, Inspection, and Failure Analysis

Proactive maintenance of the undercarriage, which constitutes up to 20-30% of the machine's lifetime operating costs, is essential for profitability.

A. Inspection Criteria:

Flange Wear: Measure the width of the flanges with calipers and compare to the specification of a new roller (often provided in service manuals). Worn, sharp, or broken flanges lose their ability to guide the track.

Tread Wear: The curved surface that contacts the track chain bushing should be inspected for wear. Significant wear creates a concave or "dished" profile, reducing the rolling surface area and increasing point load pressure.

Seal Integrity: The most common failure point. Look for:

Leaking Grease: Blackened, oily grease seeping from the seal indicates the seal has failed and contaminants are mixing with the lubricant.

Dry/Rusty Hub: A lack of grease around the hub suggests the seal has failed and all lubrication has been lost, leading to imminent bearing failure.

Rotation: Manually try to spin the roller.

Smooth & Free: Ideal condition.

Grinding or Roughness: Indicates internal bearing failure due to contamination or lack of lubrication.

Seized/Will Not Turn: The roller is completely failed. Operating the machine in this state will cause rapid grinding damage to the track chain bushings.

B. Inspection Intervals:

Severe Service (Abrasive rock, sand, mining): Every 10 operating hours.

Normal Service: Every 50 operating hours.

4. Complete Replacement Procedure

Replacing a bottom roller on a machine of this size is a major task that requires proper tools, equipment, and strict adherence to safety protocols.

Required Tools and Equipment:

Heavy-duty hydraulic floor jack (50-ton capacity or greater).

Solid, stable cribbing blocks (hardwood or steel).

High-torque hydraulic impact wrench (1" drive recommended) or a very large breaker bar with a cheater pipe.

Appropriate oversized sockets (e.g., 46 mm for M24 bolts).

Oxy-acetylene torch or induction heater (for seized bolts).

Lifting sling and a secondary machine (or crane) to handle the heavy roller.

Personal Protective Equipment (PPE): Safety glasses, steel-toed boots, heavy-duty gloves, hearing protection.

Step-by-Step Procedure:

Site Preparation: Park the excavator on a firm, level, and solid surface. Lower the attachment (bucket) flat to the ground.

Secure the Machine: Place blocks securely in front of and behind the opposite track to prevent any accidental movement.

Relieve Track Tension: Locate the grease zerking fitting on the track tension cylinder (front idler). Slowly loosen the grease valve (usually a square-head plug) to release the hydraulic pressure and slacken the track. WARNING: Stand clear of the track path as high-pressure grease and the idler can move violently.

Lift and Support: Using the jack and cribbing, carefully lift and support the track frame near the roller to be replaced. The track should be slightly off the ground.

Remove Mounting Bolts: The roller is secured by two or three large bolts threaded into the track frame. These are often corroded and extremely tight. Apply penetrating oil. Use the impact wrench or breaker bar. If seized, apply careful heat to the bolt boss on the track frame (not the bolt head) to break the corrosion.

Extract Old Roller: Once the bolts are removed, the roller may still be stuck due to rust and dirt. Use a pry bar or a puller between the roller and the track frame to break it free. Use the secondary machine to lift the roller out.

Prepare and Install: Thoroughly clean the mounting boss on the track frame. Install the new roller assembly, guiding it onto the mounting studs. Hand-tighten the new, high-tensile strength bolts. Never reuse old undercarriage bolts.

Final Torque: Using a calibrated torque wrench, torque the bolts to the manufacturer's exact specification (e.g., 1000 Nm / 737 lb-ft). This is critical for structural integrity.

Re-tension Track: Pump fresh grease into the tensioner zerking fitting until the track sag matches the specification in the operator's manual (typically 1-1.5 inches of sag between the top of the carrier roller and the track).

Final Operations: Lower the machine, remove all blocks and jacks, and perform a visual inspection of all components before operation.

5. Sourcing and Procurement Options

Genuine SDLG/OEM: Sourced from an authorized SDLG dealer. Guaranteed to meet exact factory specifications and quality. Includes a warranty. This is the most expensive option but offers the highest assurance of compatibility and performance.

Premium Quality Aftermarket (OEM Equivalent): Manufacturers like HANGONG (DPW PARTS), CQCTRACK produce undercarriage components to OEM standards. They offer excellent quality, often interchangeable with genuine parts, at a more competitive price. Highly recommended for a balance of cost and reliability.

Standard Aftermarket: Numerous other manufacturers offer replacement rollers. Quality can vary significantly. It is essential to purchase from a reputable distributor who can vouch for the material quality, heat treatment, and sealing technology. Choosing a cheaper, inferior part can be a false economy due to shorter life and potential damage to other undercarriage components.

6. Where to Buy

Official SDLG Dealer: The best source for guaranteed OEM parts that perfectly match your machine's serial number. Highest cost but ensures compatibility.

Quality Aftermarket Brands: Suppliers of DPW Machinery PARTS, ITR, CQC, or ITM parts offer excellent quality, often comparable to OEM, usually at a better price point. Ensure the supplier is reputable.

Generic Aftermarket: Lower-cost options exist, but quality can be inconsistent. For a critical component on a large machine, investing in a known quality brand is usually more cost-effective in the long run due to better durability and protection for your undercarriage.