HYUNDAI-R290LC/R305/R320LC-7Forged Idler Group for Heavy-Duty Excavator spare parts/Mining first chioce/Idlers factory supply directly

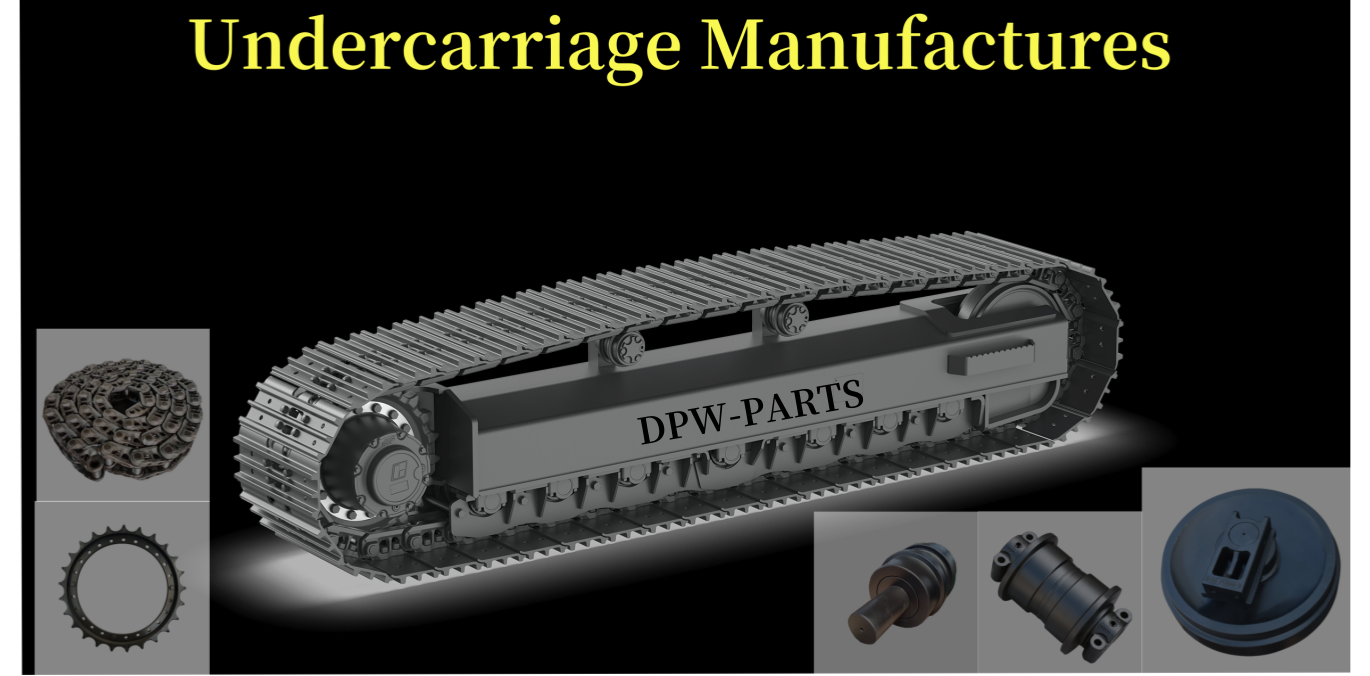

Product Specifications

Hyundai-R305-7 Forged Front Idler Assembly: Technical Overview

*Optimized for Hyundai's 30-ton Class R305-7 Crawler Excavator*

1. Core Function & Role in Undercarriage

Primary Purpose: Acts as the forward guide wheel for the excavator’s track chain, ensuring alignment, maintaining tension, and supporting machine weight.

Load Handling: Distributes operational stresses (dynamic shocks, static loads, terrain impacts) across the undercarriage.

Critical Interface: Connects to the track tensioning system for precise chain adjustment.

2. Design & Manufacturing: Forged Superiority

Material: High-tensile alloy steel (e.g., SAE 4140/4340 or equivalent), forged under extreme heat/pressure.

Forging Benefits vs. Casting:

Strength: Aligned grain structure resists cracks/fatigue.

Density: Near-zero porosity for impact absorption.

Durability: 30–50% longer lifespan in abrasive environments (rock, slag, ore).

Precision Machining: Flanges, bore, and sealing surfaces CNC-machined to Hyundai OEM tolerances (±0.05mm).

3. Assembly Components

| Part | Function |

|---|---|

| Forged Idler Wheel | Core load-bearing element; guides track chain via flanges. |

| Hardened Shaft | Transmits loads to track frame; case-hardened to 55–60 HRC. |

| Tapered Roller Bearings | Handle radial/axial loads; rated for 100,000+ cycles under full load. |

| Multi-Lip Seals | Triple-sealed design (labyrinth + lip seals) blocks mud, water, and grit. |

| Grease Fittings | Zerks for purging contaminants & relubricating bearings. |

| Mounting Housings | Bolt-on interface with track frame; includes bushings for tensioner linkage. |

4. Hyundai-R305-7 Specific Engineering

Load Rating: Engineered for the R305-7’s operating weight (≈30 tons) and breakout force (≈38,000 lbf).

Track Compatibility: Matches R305-7 chain pitch (e.g., 216mm), link height, and shoe width.

Tensioning System: Integrates with Hyundai’s hydraulic tensioner for rapid track adjustment.

Sealing System: Optimized for muddy/wet conditions (common in R305-7 applications like trenching).

5. Performance Advantages

Extended Service Life: Forged construction withstands 8,000–10,000 hours in severe duty vs. 5,000–6,000 for cast idlers.

Reduced Downtime: Robust seals cut bearing failure rates by 40–60% in contaminated environments.

Track Stability: Prevents derailment during side-slope operation or high-swing maneuvers.

Cost Efficiency: Lowers total ownership cost by protecting adjacent undercarriage parts (rollers, sprockets).

6. Target Applications & Environments

Primary Machine: Hyundai R305-7 Excavator (30-ton class).

Typical Use Cases:

Road construction & quarrying

Deep excavation/trenching

Demolition with heavy impact loads

Forestry/marshland operations

Harsh Conditions: Performs in mud, sand, rocky terrain, and sub-zero to +50°C temperatures.

7. Failure Modes & Mitigation

| Failure Risk | Cause | Prevention |

|---|---|---|

| Flange Wear | Track chain abrasion | Monitor chain stretch; replace if >3% |

| Bearing Seizure | Seal failure → contamination | Quarterly grease purges; inspect seals |

| Shaft Fracture | Overload/impact damage | Avoid collisions; use OEM-spec parts |

| Bolt Fatigue | Improper tensioning | Retorque mounting bolts per schedule |

8. Maintenance Best Practices

Lubrication: Use Hyundai-recommended EP grease (NLGI #2) every 50–100 operating hours.

Inspection: Check every 250 hours for:

Seal leaks

Abnormal flange wear (>10% thickness loss)

Track tension (sag 20–40mm mid-span)

Tension Adjustment: Only use Hyundai’s hydraulic system – never force-adjust with tools.

9. Why Genuine Hyundai OEM Matters

Precision Fit: Guarantees alignment with R305-7 track geometry (avoids accelerated roller/sprocket wear).

Load Integrity: Matches factory load ratings for safe heavy lifting.

Warranty Compliance: Required for Hyundai’s undercarriage warranty (typically 2–5 years).

Performance Assurance: Third-party idlers risk chain derailment or frame damage due to tolerance gaps.

10. Specifications Summary

Weight: 160–180 kg (varies by revision)

Bore Diameter: 80–90mm (tapered for bearing press-fit)

Flange Height: 55–65mm

Bearing Type: Timken-style tapered rollers (OEM: KOYO/NTN)

Seal Type: Triple-lip + labyrinth + exclusion seal