HYUNDAI 81QE11010 R1200/R1250 Track Lower Roller Assembly/Heavy duty crawler excavator undercarriage part supplier-DPW PARTS(HAN GONG)

Product Specifications

Engineering White Paper: The DPW PARTS HAN GONG HYUNDAI 81QE11010 R1250 Track Bottom Roller Assembly

Document Identifier: WP-UC-DPWHG-001

Revision: 1.0

Publication Date: December 8, 2025

Classification: Public Technical Specification

1.0 Executive Summary & Strategic Product Positioning

This document provides a comprehensive engineering analysis and technical specification for the HYUNDAI 81QE11010 Track Bottom Roller Assembly, engineered and manufactured by DPW PARTS (HAN GONG) for the R1250-class heavy-duty crawler excavator. In the severe-duty cycle of mining, quarrying, and large-scale earthmoving, the undercarriage system is the foundational component bearing the ultimate brunt of operational stress, accounting for a significant portion of a machine's total lifetime operating cost and downtime. The bottom roller, a critical load-bearing element within this system, directly influences machine stability, traction efficiency, and the wear rate of adjacent components.

The DPW PARTS HAN GONG 81QE11010 assembly transcends the definition of a standard replacement part. It is the product of a targeted Original Design Manufacturing (ODM) philosophy, where deep analysis of field failure modes informs a re-engineering process focused on extending service life and improving total cost of ownership (TCO). While manufactured to guarantee perfect dimensional interchangeability with the OEM HYUNDAI R1250 specification, this assembly incorporates proprietary material science, advanced heat treatment protocols, and a sealing system engineered for the most abrasive and contaminant-rich environments. This white paper details the technical rationale behind these enhancements, positioning the DPW PARTS HAN GONG roller as a superior solution for fleet managers and equipment owners prioritizing machine availability and operational economy over mere initial purchase price.

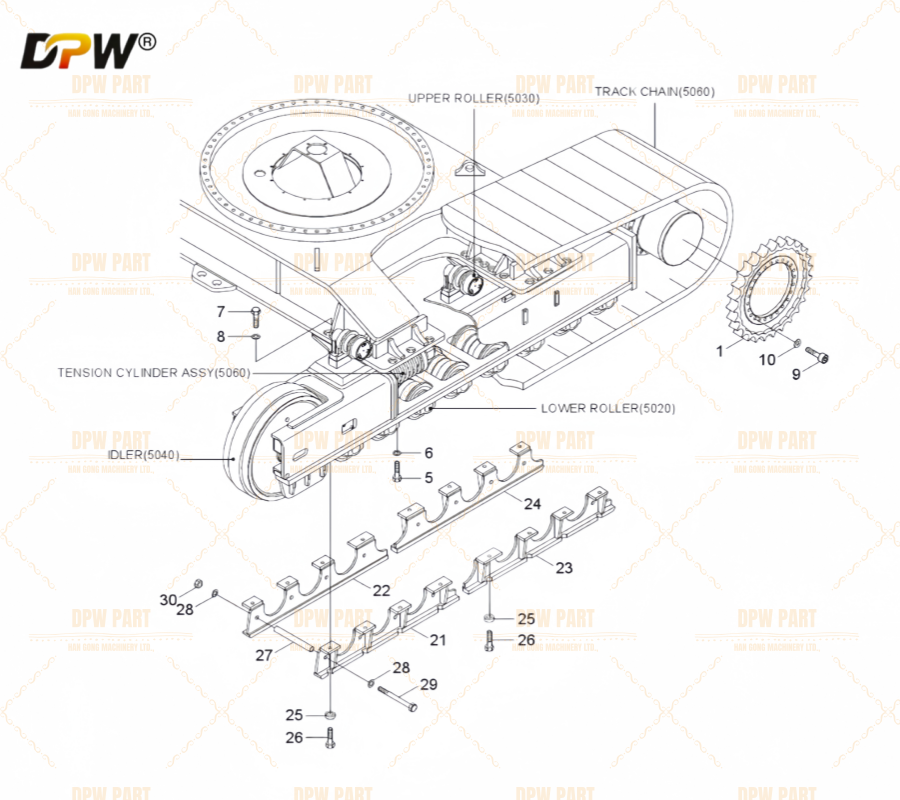

2.0 Anatomical and Functional Analysis of the Track Bottom Roller

2.1 Role within the Undercarriage Ecosystem

The crawler undercarriage is a complex, interdependent system. The Track Bottom Roller (alternately termed Lower Roller or Support Roller) performs three non-negotiable primary functions:

Primary Load-Bearing: It supports the machine's substantial weight—over 100 tons for the R1250—transferring static and dynamic loads from the mainframe through the track chain to the ground.

Track Guidance and Alignment: Its dual-flange design contains the track chain, preventing lateral derailment during high-side-load operations such as turning and side-hill grading.

Wear Management: By providing a smooth, hardened rolling surface, it minimizes friction with the track chain bushings, directly protecting more expensive components like the track links and sprockets from accelerated wear.

Failure of this component manifests as increased rolling resistance (elevating fuel consumption), abnormal and costly wear on track links, and ultimately, catastrophic derailment or undercarriage frame damage.

2.2 Systemic Integration of the 81QE11010 Assembly

The HYUNDAI 81QE11010 is a fully sealed and pre-lubricated assembly. It is engineered as a complete, ready-to-install unit comprising the roller wheel, a high-strength alloy steel shaft, a high-load-capacity bearing/bushing system, and a multi-stage sealing package. This "unitized" design eliminates the need for field servicing, ensures optimal internal lubrication from first operation, and guarantees that all internal components are protected to the same stringent standard.

3.0 Technical Specifications & Engineering Enhancements

The following table details the core specifications of the DPW PARTS HAN GONG assembly, with explicit commentary on the engineering advantages over baseline designs.

| Parameter Category | DPW PARTS HAN GONG 81QE11010 Specification | Engineering Significance & Enhancement |

|---|---|---|

| OEM Compatibility | Direct interchange for HYUNDAI R1250 (81QE11010). | Guaranteed geometric fit; no modification required, ensuring perfect alignment and load distribution. |

| Roller Wheel Material | Forged 50Mn / 40SiMnTi High-Alloy Steel. | Superior to standard carbon steels. Manganese (Mn) and Silicon-Manganese-Titanium (SiMnTi) alloys provide exceptional hardenability and core toughness, resisting impact fracture. |

| Heat Treatment Process | Precision Computer-Controlled Induction Hardening. | Allows for exact control over the hardness profile, creating a distinct, optimized transition between surface and core. |

| Surface Hardness | 58 - 62 HRC (Case Depth: 8 - 12 mm). | Extreme surface hardness provides maximum resistance to abrasive wear from ground materials and track chain contact. The deep case ensures this hardness persists throughout the component's life. |

| Core Hardness & Toughness | 38 - 42 HRC. | A ductile, tough core absorbs high-impact loads (e.g., dropping over rock ledges) without catastrophic brittle fracture, a common failure point in poorly manufactured rollers. |

| Bearing/Shaft System | Case-Hardened Alloy Steel Shaft with Oil-Impregnated Sintered Bronze Bushings. | The shaft is ground to a mirror finish for minimal friction. Sintered bronze bushings offer high load capacity and provide a secondary, embedded lubrication source during extreme conditions. |

| Sealing System | Multi-Labyrinth Design with Floating Metal Wear Ring and Dual-Lip Radial Seal (NBR/Viton®). | The DPW PARTS HAN GONG critical differentiator. The labyrinth expels large contaminants; the floating wear ring protects the primary seal from abrasive grit; the dual-lipped radial seal provides a final, positive barrier against fine silt and water ingress. This system is validated in slurry tank testing. |

| Internal Lubricant | High-Viscosity, Lithium Complex Extreme Pressure (EP) Grease. | Formulated to maintain structural integrity and lubricity under high pressure and across a wide temperature range (-30°C to 150°C). |

| Quality Certification | Manufactured under ISO 9001:2015 Quality Management Systems. | Ensures process control, traceability, and consistent batch-to-batch quality, a hallmark of professional OEM and ODM suppliers. |

4.0 The DPW PARTS HAN GONG ODM Manufacturing Philosophy: Precision Beyond Blueprint

As an ODM specialist, DPW PARTS (HAN GONG) operates on a principle of applied metallurgy and failure-mode mitigation. The manufacturing process is a vertically integrated, closed-loop system:

Forging & Material Science: Starting with certified alloy steel billets, closed-die forging is employed to create the roller blank. This process aligns the metal's grain flow with the component's shape, dramatically enhancing its ultimate tensile strength and fatigue resistance compared to cast or fabricated alternatives.

Precision Machining: CNC machining centers achieve tolerances within ISO 2768-mK standards. Critical to performance is the precise machining of the seal gland geometry, which is optimized for the proprietary multi-labyrinth seal package.

Controlled Heat Treatment: The induction hardening process is not merely about achieving a high surface number. The precise control of frequency, power, and quench rate is what creates the optimal, deep-hardened case while preserving the necessary core ductility—a balance that defines component life.

Clean-Room Assembly & Validation: Final assembly occurs in a controlled environment. Each unit is purged with its specified grease and undergoes a final operational test for rotational smoothness and seal integrity. This mirrors the advanced manufacturing practices of leading undercarriage specialists.

5.0 Comparative Analysis & Total Cost of Ownership (TCO) Proposition

The value of the DPW PARTS HAN GONG assembly is best understood through a comparative TCO lens, which accounts for initial price, service life, and impact on adjacent components.

TCO Conclusion: While the initial investment in the DPW PARTS HAN GONG assembly may be higher than a generic part, its extended service life and role in protecting the entire undercarriage system result in a significantly lower cost per operating hour. This aligns with the core need of modern equipment fleets: maximizing machine availability and productivity.

6.0 Installation Protocol & Field Performance Assurance

Installation: The assembly is a direct bolt-on replacement. We recommend following OEM torque specifications and sequences for mounting bolts. Prior to installation, the mounting pads on the track frame should be cleaned to ensure a flat, secure fit.

Performance Monitoring: During routine undercarriage inspections (recommended every 250 service hours), operators should check for:

Free Rotation: Minor drag is normal; seized or very stiff rotation indicates internal failure.

Seal Integrity: Significant grease leakage or the presence of a "wet" path around the seal periphery suggests seal compromise.

Flange and Rim Wear: Even wear is expected. Grooving, severe spalling, or asymmetric wear patterns may indicate track misalignment or other undercarriage issues.

Warranty & Support: The DPW PARTS HAN GONG HYUNDAI 81QE11010 Track Bottom Roller Assembly is backed by a comprehensive warranty, supported by technical documentation including material certificates and factory test reports.