EX3000 Track Roller Assembly/Hitachi Heavy duty construction Mining chassis components manufacture and supplier

Product Specifications

1. Overview of Track Roller Assembly

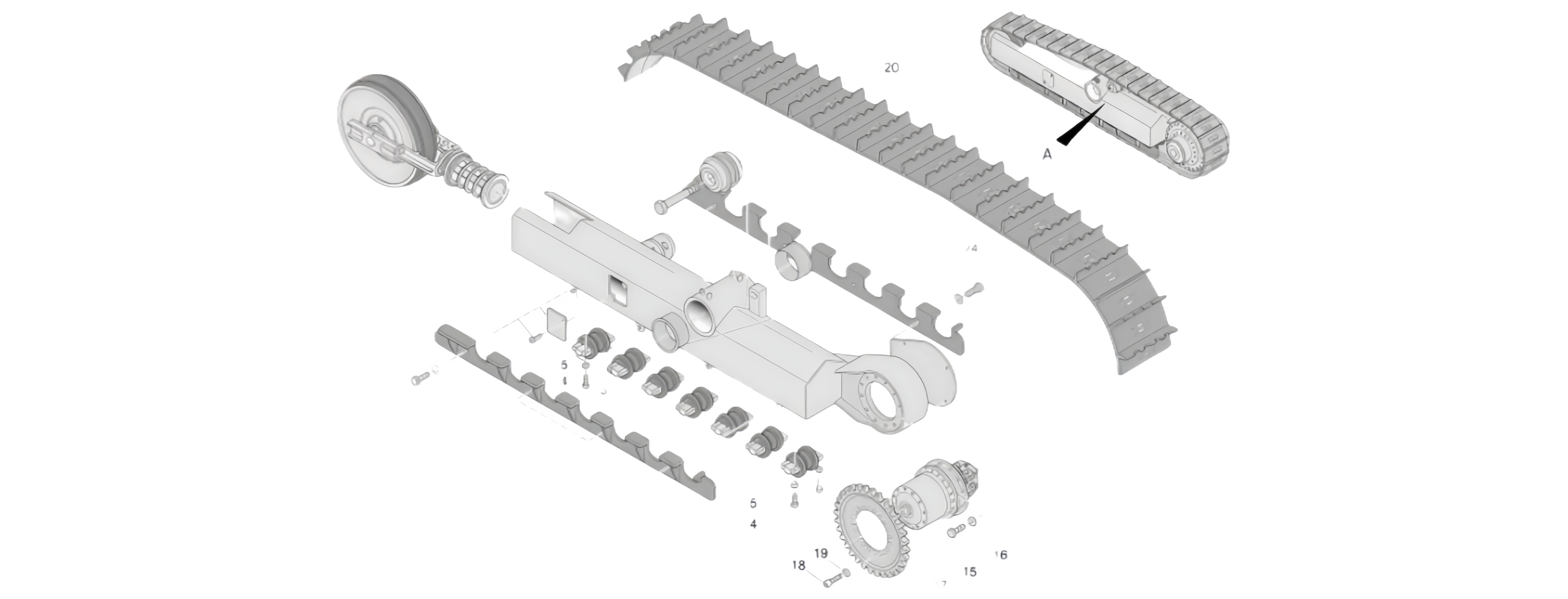

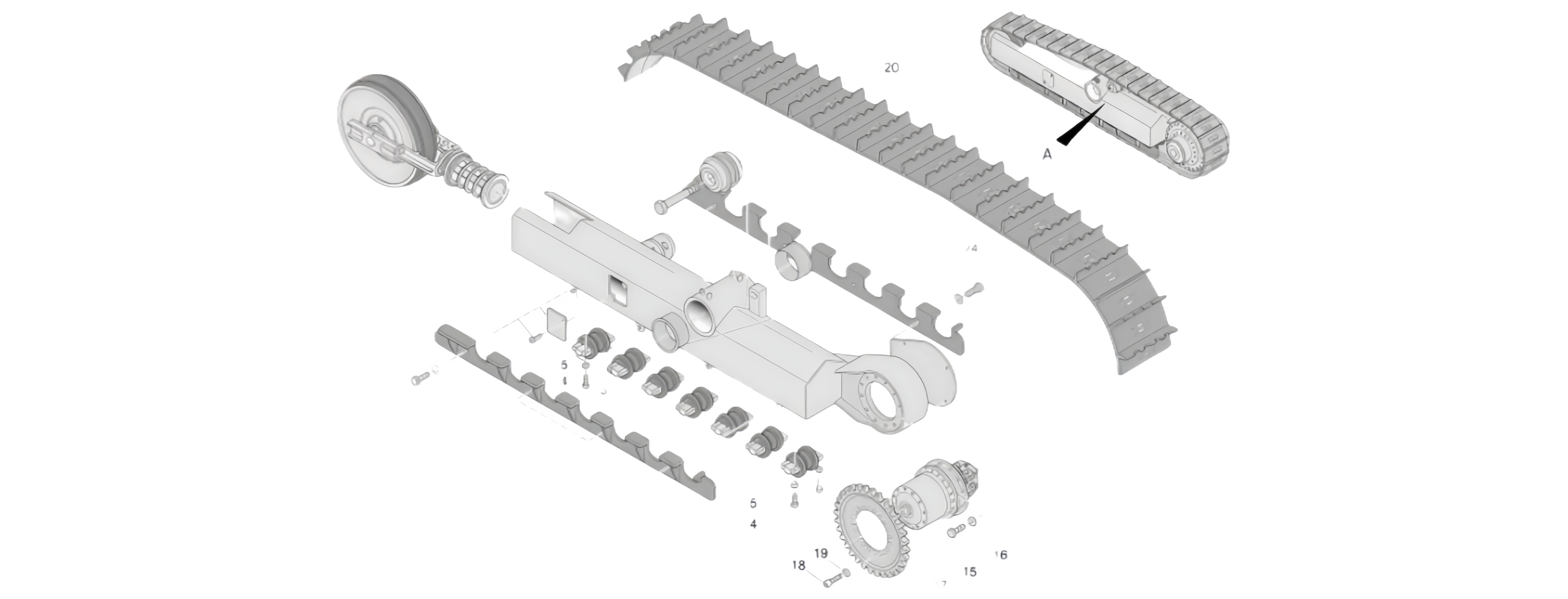

The Hitachi EX3000 track roller assembly is a critical component in the undercarriage system of the Hitachi EX3000 excavator. It supports the weight of the machine and guides the track chain, ensuring smooth operation and stability during excavation tasks. The assembly consists of several key components, including rollers, bearings, seals, axles, and retaining components, all working together to withstand heavy loads and harsh operating conditions.

Key functions include:

Weight Distribution: Rollers distribute the machine's weight evenly across the track chain.

Guidance and Alignment: Ensures the track moves smoothly along the undercarriage frame.

Impact Absorption: Helps absorb shocks and vibrations during operation.

2. Technical Specifications

While specific specifications for the Hitachi EX3000 were not found in the search results, general technical aspects of track roller assemblies based on industry standards include:

Materials: High-strength steel components (e.g., rollers, axles) with hardened surfaces for wear resistance. Seals often use advanced materials like nitrile rubber or polyurethane for durability .

Heat Treatment: Critical components like axles and rollers typically undergo heat treatment (e.g., quenching and tempering) to achieve surface hardness of approximately HRC 50-60 for optimal wear resistance .

Dimensional Precision: Axles and bearings require high manufacturing precision, with axle diameter tolerances typically maintained within ±0.002mm to ±0.019mm to ensure proper fit and function .

Load Capacity: Designed to support extreme weights (EX3000 likely exceeds 200 tons), with dynamic load ratings typically exceeding static weights by 2-3 times.

Table: Common Track Roller Components and Specifications

| Component | Material | Key Characteristics | Function |

|---|

| Roller | Hardened alloy steel | Surface hardness HRC 50-60 | Support machine weight, guide track |

| Bearing | Chrome steel | Precision graded | Reduce friction, support loads |

| Seal | Nitrile rubber/Polyurethane | Multi-labyrinth design | Exclude contaminants, retain grease |

| Axle | Alloy steel | High tensile strength | Support rollers, transmit loads |

| Retaining Rings | Spring steel | High elastic limit | Secure components axially |

3. Installation and Maintenance ProceduresProper installation and maintenance are crucial for longevity and performance: Installation Precautions: Ensure all components are clean and free of damage before assembly. Use proper lifting equipment due to heavy weights involved. Follow manufacturer's torque specifications for all fasteners. Apply appropriate lubricants to seals and bearings during assembly .

Maintenance Practices: Regular Inspection: Check for wear patterns, seal damage, and proper lubrication. Lubrication: Use recommended greases and maintain proper intervals. Seal Inspection: Monitor for leaks or contamination entry points . Bearing Adjustment: Check preload and adjust as necessary per specifications.

Wear Monitoring: Measure roller flange diameters regularly to track wear. Monitor for abnormal noise or vibration during operation. Check for proper track tension alignment.

🔧 4. Common Issues and SolutionsPremature Wear: Often caused by contamination ingress through damaged seals or improper lubrication. Solution: Use high-quality seals and maintain proper lubrication schedules . Bearing Failure: Typically results from improper installation, contamination, or overloading. Solution: Ensure precise installation procedures and regular maintenance. Seal Leakage: Can be caused by seal damage or improper installation. Solution: Use genuine seal kits and follow installation specifications carefully . Abnormal Noise: May indicate bearing problems or misalignment. Solution: Immediate inspection and component replacement if necessary.

5. Sourcing Options: OEM vs. AftermarketWhen replacing track roller assemblies, consider these options: OEM (Genuine Hitachi Parts): Advantages: Guaranteed compatibility, engineered quality, and warranty support. Considerations: Higher initial cost but potentially lower total cost of ownership.

Aftermarket Alternatives: Quality Variations: Some manufacturers offer components with specifications similar to OEM, using materials like 40Mn/45Mn steel with hardness HRC 52-58 . Cost Savings: Typically 30-50% lower than OEM prices. Verification Needed: Request material certifications and test reports when considering aftermarket options.

Replacement Recommendations: For critical components like bearings and seals, consider OEM parts for optimal performance. Non-critical components may be sourced from reputable aftermarket suppliers. Always verify compatibility using your machine's serial number.

6. Practical RecommendationsPreventive Maintenance: Implement regular inspection schedules to identify wear early and prevent catastrophic failures. Pay special attention to seal conditions and lubrication quality . Proper Installation: Use trained technicians and follow manufacturer specifications precisely. Improper installation can significantly reduce component life. Genuine Parts Consideration: For critical components, consider genuine parts to ensure reliability and maintain warranty coverage. Documentation: Keep detailed records of maintenance and replacements to predict future service needs and costs. Technical Resources: Utilize Hitachi's technical documentation and support services for specific guidance on your EX3000 model.

7. Additional ResourcesFor more detailed technical information: Consult Hitachi official service manuals for EX3000 Contact authorized Hitachi dealers for specific part numbers Utilize Hitachi's online parts databases and support services

|

Get the latest price? We'll respond as soon as possible