DRESSTA UG244D0T/UF244D0T TD25M DF/SF Track Bottom Roller Assy/Heavy duty Tractor and Dozer undercarriage part source factory and manufacturer

Product Specifications

1. Product Identification & Functional Overview

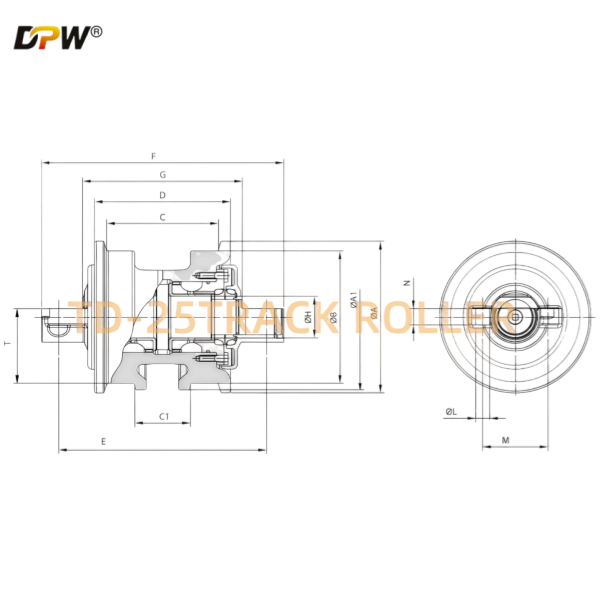

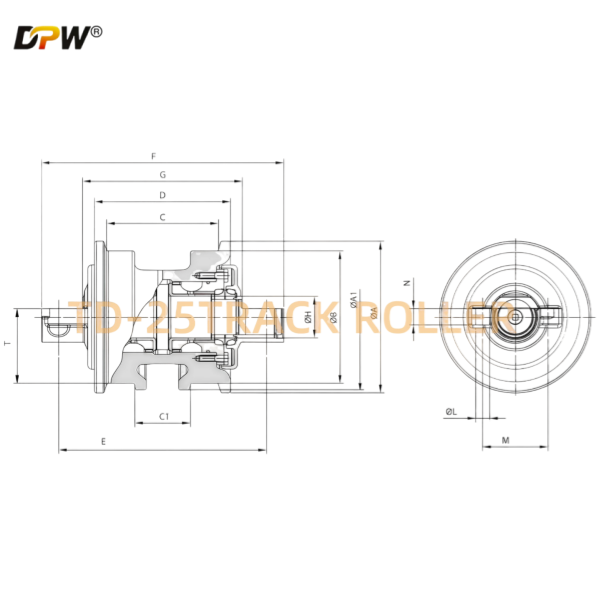

OEM Model Reference: Dressta UF244D0T/UG244D0T

Application: Designed for the Dressta TD25M series crawler bulldozer and other compatible heavy-duty tractors.

Component Name: Double Flange Track Bottom Roller Assembly (Lower Roller)

Manufacturer Profile: A specialized factory and source for OEM-quality bulldozer and crawler tractor undercarriage systems.

The Double Flange Track Bottom Roller is a fundamental load-bearing component within the crawler undercarriage of heavy-duty equipment like the Dressta TD25M. Its primary functions are:

Load Support: Bears the substantial weight of the bulldozer, distributing the load evenly along the bottom section of the track chain to ensure ground stability and prevent excessive sinkage.

Track Guidance & Alignment: The dual, robust flanges on both sides of the roller securely contain the track chain, preventing lateral slippage and derailment during aggressive dozing, grading, and turning maneuvers. This is critical for maintaining straight travel and operational safety.

Friction Reduction: Provides a smooth, hardened, and rotating surface for the track chain to travel over, minimizing rolling resistance and power loss from friction.

2. Technical Specifications & Engineering Design

Our manufacturing process is engineered to meet the extreme demands of large bulldozers, where impact loads and abrasive wear are significantly higher than on standard excavators.

Material & Forging:

Roller Wheel: Fabricated from hot-forged, high-carbon, high-manganese steel (e.g., 55Mn, 60Si2Mn). The die-forging process creates a continuous grain flow that dramatically enhances the component's impact strength and fatigue life, making it ideal for the shock loads encountered in rock and demolition sites.

Shaft & Bushings: The core shaft is precision-machined from high-strength alloy steel (42CrMo), while the internal bushings are made from wear-resistant, sintered bronze or steel-on-steel composites for maximum durability under high rotational forces.

Advanced Heat Treatment:

Core Toughness (Quenching & Tempering): The entire roller undergoes a controlled Q&T process to achieve a tough, ductile core structure (approx. 35-42 HRC), essential for absorbing massive impact loads without cracking.

Surface Hardness (Induction Hardening): The entire rolling contact surface and the critical guide flanges are induction hardened to a depth of 6-10mm, achieving a supreme surface hardness of 58-63 HRC. This provides unparalleled resistance to the severe abrasive wear caused by sand, rock, and other abrasive materials.

Heavy-Duty Sealing System:

The longevity of the roller in contaminated environments is secured by a multi-stage, heavy-duty sealing system:Primary Seal: A robust, spring-loaded radial lip seal made of high-quality Nitrile rubber (NBR) or Hythane® for superior temperature and abrasion resistance.

Labyrinth Seal: A complex, multi-path mechanical seal designed to create a near-impenetrable barrier, deflecting and ejecting abrasive contaminants like mud, clay, and rock dust.

Grease Barrier: The seal cavity is packed with a high-viscosity, extreme-pressure (EP) lithium complex grease, creating a positive pressure zone that actively prevents contaminant ingress.

Lubrication & Service: Designed as a sealed-for-life assembly, the internal cavity is permanently lubricated. A standard grease fitting is provided for maintenance of the outer seal cavity and for pressure relief.

3. Manufacturing Process & Quality Assurance

As a dedicated undercarriage factory, we implement a rigorous, vertically integrated production protocol.

Manufacturing Workflow: Raw Material Certification → Die Forging → Rough Machining → Quenching & Tempering → Deep Induction Hardening → Precision CNC Finish Machining → Seal & Bearing Assembly → Performance Testing → Painting & Packaging.

Stringent Quality Control:

Dimensional Accuracy: 100% inspection using calibrated gauges and CMM (Coordinate Measuring Machines) to ensure perfect OEM interchangeability.

Hardness Verification: Rockwell and Brinell testing on both core and wear surfaces to validate heat treatment specifications.

Non-Destructive Testing (NDT): Magnetic Particle Inspection (MPI) is used on 100% of forged components to detect any subsurface flaws or forging defects.

Rotational Torque & Seal Integrity Test: Every assembled roller is tested for smooth rotation within specified torque limits and undergoes a pressure decay test to confirm the sealing system's integrity.

4. Common Failure Modes & Durability Advantages

Our rollers are engineered to overcome the common failure points in severe dozer applications:

Rapid Flange Wear: Mitigated by the deep, induction-hardened flanges.

Seal Failure & Bearing Contamination: Prevented by the heavy-duty, multi-stage labyrinth seal design.

Roller Seizure: Avoided through precise internal tolerances and contaminant-free lubrication.

Core Cracking or Fracture: Resisted by the superior impact strength of the forged and Q&T-treated core material.

5. Our Factory: A Reliable Source for Heavy-Duty Undercarriage

We position ourselves as a strategic manufacturing partner for the global heavy machinery market, offering:

OEM Direct Interchangeability: Our parts are manufactured to the exact specifications of the original Dressta components, ensuring perfect fit and function.

Integrated Manufacturing: Full in-house control over forging, machining, and heat treatment guarantees consistent quality, cost efficiency, and supply chain reliability.

Proven Performance in Severe Duty: Our components are designed from the outset for the most demanding applications, including mining, quarrying, and large-scale earthmoving.

Global Supply Chain Capability: We possess the capacity and logistics expertise to serve OEMs, distributors, and large end-users worldwide, ensuring timely delivery to minimize machine downtime.