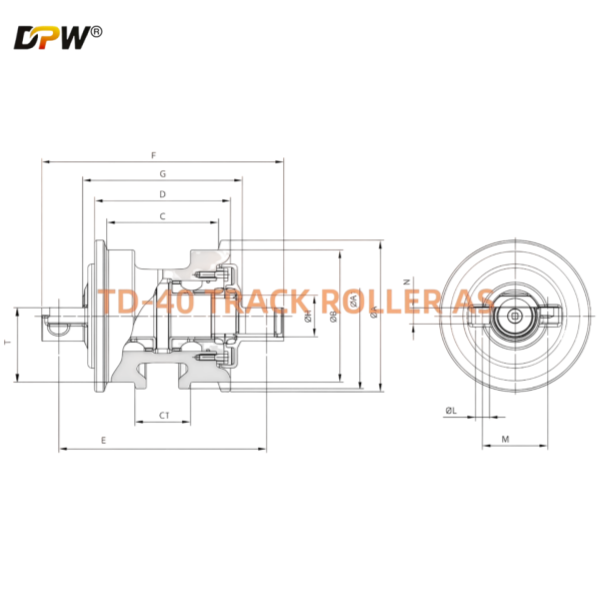

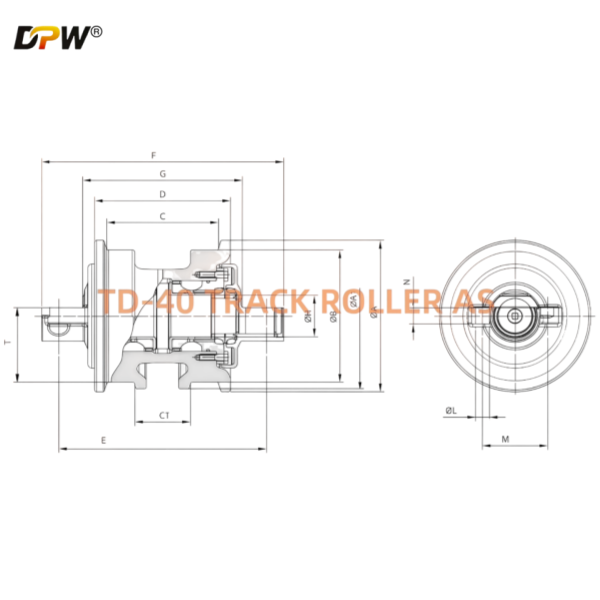

DRESSTA 395140210/395140213 TD40E SF/DF Track Bottom Roller Assy/Heavy duty Tractor and Dozer Chassis component source factory and manufacturer-HANGONG MACHINERY PARTS

Product Specifications

1. Product Identification & Functional Overview

OEM Part Numbers: 395140210 (Single Flange), 395140213 (Double Flange)

Application: DRESSTA TD40E Series Large Crawler Bulldozers.

Component Name: Track Bottom Roller Assembly (Lower Roller) - Single Flange (SF) & Double Flange (DF)

Manufacturer Profile: A premier source factory for OEM-quality, heavy-duty bulldozer and crawler tractor undercarriage systems.

The Track Bottom Roller is a critical structural component within the undercarriage of a high-horsepower bulldozer like the Dressta TD40. It is subjected to immense static and dynamic loads during dozing, pushing, and ripping operations.

Primary Function:

Load Support: Carries the machine's massive weight and distributes it evenly across the lower track chain, providing stability and flotation.

Track Guidance:

Double Flange (DF) Roller (395140213): The two flanges securely guide the track chain, preventing lateral derailment. These are typically used on the outer positions to contain the track.

Single Flange (SF) Roller (395140210): Features one guiding flange, with the other side being flat. These are commonly used in the intermediate positions, working in conjunction with the double flange rollers to maintain alignment while allowing for efficient track articulation.

Friction Reduction: Provides a hardened, rotating surface for the track chain to travel over, minimizing rolling resistance and power loss.

2. Technical Specifications & Engineering Design

Our manufacturing process is engineered to withstand the extreme impact and abrasive wear characteristic of a 400+ horsepower bulldozer's working environment.

Material Science & Forging:

Roller Wheel: Fabricated from premium 60Si2Mn or 55Mn spring steel via closed-die forging. This process ensures a superior grain flow that follows the roller's contour, providing exceptional yield strength and impact toughness—far exceeding the capabilities of cast rollers.

Shaft & Bushings: The shaft is machined from high-tensile alloy steel (42CrMo), heat-treated for core strength. Internal bushings are manufactured from high-density, wear-resistant sintered alloy to ensure longevity under extreme rotational pressures.

Advanced Heat Treatment Regimen:

Core Toughness (Quenching & Tempering): The entire component undergoes a precise Q&T process to achieve a uniform, tough core hardness (approx. 35-42 HRC). This is essential for absorbing the massive shock loads encountered in rock and demolition work without fracturing.

Surface Hardness (Deep Induction Hardening): The rolling contact path and the critical guiding flanges are subjected to deep induction hardening, achieving a case depth of 8-12mm and a surface hardness of 59-63 HRC. This provides maximum resistance to abrasive wear from rock, sand, and other aggregates.

Heavy-Duty, Multi-Stage Sealing System:

Seal integrity is paramount for component life. We employ a state-of-the-art sealing system designed for the most contaminated environments:Primary Seal: A heavy-duty, spring-loaded radial lip seal constructed from advanced polymer compounds (e.g., Hythane® or NBR) for superior heat and abrasion resistance.

Labyrinth Seal: A complex, multi-channel mechanical seal that creates a tortuous path, effectively deflecting and ejecting abrasive contaminants like slurry and fine rock dust.

Grease Barrier: The seal cavity is packed with a high-temperature, high-load, waterproof lithium complex grease, creating a positive pressure barrier that actively repels contaminant ingress.

Lubrication: Designed as a sealed-for-life assembly, the internal bearing cavity is permanently lubricated. A standard grease fitting is provided for maintaining the outer seal barrier and for pressure relief.

3. Manufacturing Process & Quality Assurance

As a specialized undercarriage factory, we maintain strict control over our vertically integrated production process.

Manufacturing Workflow: Raw Material Spectroscopy → Die Forging → Rough Machining → Normalizing → Quenching & Tempering → Deep Induction Hardening → Precision CNC Finish Machining → Seal & Bearing Assembly → Performance & Seal Testing → Shot Blasting & Painting.

Comprehensive Quality Control Protocol:

Dimensional Metrology: 100% inspection using precision gauges and CMM (Coordinate Measuring Machines) to guarantee perfect OEM interchangeability and fit.

Hardness & Depth Verification: Rockwell, Brinell, and portable hardness testers are used to verify core and surface hardness, as well as the effective case depth of the induction hardening.

Non-Destructive Testing (NDT): 100% of forged blanks undergo Magnetic Particle Inspection (MPI) to detect any subsurface flaws or material imperfections before machining.

Rotational Torque & Seal Integrity Test: Every assembled roller is tested for smooth rotation within a specified torque range and undergoes an air pressure decay test to validate the complete sealing system's integrity against leakage.

4. Common Failure Modes & Engineering Solutions

Our rollers are specifically designed to prevent the most common and costly failure modes in heavy-duty dozer applications:

Premature Flange Wear-Out: Combated by the deep, ultra-hard induction-hardened flanges.

Seal Failure & Bearing Spalling: Mitigated by the heavy-duty, multi-stage labyrinth seal that keeps the internal bearing environment clean.

Roller Seizure: Prevented through precise internal tolerances and the contaminant-free environment maintained by the sealing system.

Core Cracking from Impact: Resisted by the superior impact strength and fatigue resistance provided by the forged and properly heat-treated core.

5. Our Factory: Your Strategic Undercarriage Source

We are a trusted manufacturer for global mining, quarrying, and heavy construction sectors, offering:

OEM Direct Replacement: Our parts are manufactured to the exact original specifications, ensuring flawless performance and compatibility with the Dressta TD40E.

Integrated Vertical Manufacturing: Full in-house control from forging to final assembly ensures unmatched quality consistency, cost efficiency, and supply chain security.

Engineered for Extreme Duty: Our components are designed from the ground up for the most severe applications, delivering service life that meets or exceeds OEM standards.

Global Logistics & Support: We possess the capacity and expertise to serve OEMs, large distributors, and major end-users worldwide, ensuring reliable delivery to minimize critical machine downtime.