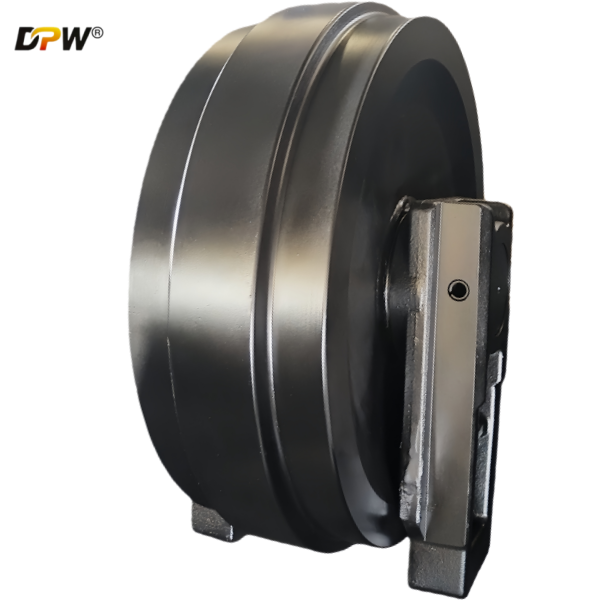

DOOSAN K1051229 DX700 Guide Wheel Assy/Track Idler Wheel AS-Heavy duty undercarriage manufacturer expert-DPW PARTS

Product Specifications

DOOSAN K1051229 DX700 Guide Wheel Assembly (Track Idler Wheel) by DPW PARTS: A Comprehensive Technical Exposition for Heavy-Duty Undercarriage Applications

Abstract: This document provides a definitive, in-depth technical analysis of the DOOSAN K1051229 DX700 Guide Wheel Assembly, also designated as a Track Idler Wheel (AS-Heavy Duty Grade). Manufactured by DPW PARTS, a specialist in heavy-duty undercarriage components, this assembly is engineered as a direct replacement and performance upgrade for the Doosan DX700 series large hydraulic excavators. The following exposition details its specifications, engineering features, manufacturing protocols, and operational superiority within the context of extreme-duty cyclical loading and abrasive environments.

1. Product Definition & Technical Classification

The DOOSAN K1051229 Guide Wheel Assy/Track Idler Wheel is a mission-critical component within the crawler undercarriage system. Its primary functions are:

Track Guiding & Tensioning: To maintain precise lateral alignment of the track chain and, in conjunction with the recoil mechanism, provide optimal track tension to prevent derailment and minimize power loss.

Dynamic Load Distribution: To absorb and transfer vertical loads and shock impacts from the track chain to the main undercarriage frame.

Forward Support: To serve as the forward pivot point for the track link assembly.

DPW PARTS classifies this component under its AS (Aftermarket – Super Duty) category. This designation signifies a component that not only meets but exceeds original equipment manufacturer (OEM) specifications through enhanced materials, refined geometries, and rigorous quality control, targeting operations in mining, quarrying, and large-scale earthmoving where unscheduled downtime carries prohibitive costs.

2. Technical Specifications & Design Parameters

OEM Reference & Compatibility: Part Number K1051229, engineered for direct interchangeability with the Doosan DX700 (approx. 65-72 metric tons operating weight) excavator undercarriage.

Dimensional Integrity: Manufactured to restore original track gauge, pitch alignment, and interface dimensions with the track shoe (typically 650mm/700mm triple-bar) and recoil assembly.

Core Construction:

Wheel Body: Fabricated from high-integrity, low-alloy steel plate via CNC-controlled welding or precision forging, followed by stress-relieving to eliminate internal stresses.

Flange: Profiled for maximum contact with track link bushings, featuring hardened wear surfaces to resist flange grooving.

Hub & Bushing: Integrates a robust, replaceable bronze alloy bushing (e.g., SAE CA932/C93700) or a hardened steel sleeve. The bushing provides a superior, wear-resistant bearing surface for the idler axle.

Bearing & Seal System (Critical Differentiator):

Sealing Architecture: Employs a multi-stage, labyrinth-style seal system. This often combines a primary radial lip seal (from advanced compounds like Hydrogenated Nitrile Butadiene Rubber - HNBR) with a floating metal face seal and grease-purged cavity. This design creates successive barriers against contamination (abrasive dust, slurry) and retains lubricant effectively.

Lubrication Interface: Features a standard zerk fitting (ISO 12651) protected by a debris-deflecting cap, allowing for routine high-pressure grease injection to replenish the internal cavity and purge potential contaminants.

3. Engineering Design & Reinforcement Technology

Materials Science:

Flange/Rim Material: Utilizes air-quenched and tempered alloy steel (e.g., equivalent to ASTM A514 Grade B or JIS SMn443), achieving a bulk hardness of 350-400 HB for optimal wear resistance without brittleness.

Seal-Grade Surfaces: Machined sealing surfaces on the hub and axle stub are finished to a low roughness average (Ra < 0.8 µm) to ensure perfect seal lip engagement and longevity.

Structural Analysis:

The component's design is validated through Finite Element Analysis (FEA) to identify and reinforce stress-concentration zones, particularly at the transition between the hub and the disc. This ensures uniform stress distribution under multi-axial loading.

The internal ribbing and web geometry are optimized for stiffness-to-weight ratio, preventing deflection that can accelerate seal failure and uneven wear.

Thermal & Wear Management:

The bushing bore is engineered with grease distribution grooves to ensure even lubricant film formation across the entire bearing surface, reducing friction-induced heat.

Flange sides may be treated with localized hardening or equipped with bolt-on wear rings (in specific designs) to provide a replaceable wear surface, significantly extending the core assembly's service life.

4. Manufacturing & Quality Protocol (DPW PARTS Expertise)

DPW PARTS implements a vertically integrated manufacturing and quality assurance process:

Incoming Material Verification: Raw materials are certified against mill test reports (MTRs) and subject to spectroscopic analysis.

Precision Machining: CNC turning and boring centers ensure critical tolerances:

Bushing bore diameter and concentricity: Held within IT7 grade tolerance.

Flange run-out: Typically less than 0.5mm Total Indicator Reading (TIR).

Heat Treatment: Conducted in computer-controlled atmosphere furnaces with precise temperature profiling for repeatable hardness and material properties.

Assembly & Lubrication: Clean-room assembly practices are employed. The sealing chamber is pre-packed with a high-temperature, high-adhesion lithium complex or calcium sulfonate grease.

Final Validation:

Dimensional Audit: 100% critical dimension inspection.

Rotation Test: Each assembly is rotated under low load to verify smooth operation and absence of binding.

Seal Pressure Test (if applicable): Subjected to air pressure test to verify seal integrity before shipment.

5. Application, Maintenance & Lifecycle

Target Operating Conditions: Ideal for severe abrasion (rock, slag, sand) and high-impact environments common in mining, heavy construction, and demolition.

Installation Guidelines:

Critical to clean the mounting axle/stub thoroughly and inspect for wear or scoring.

Follow OEM-specified torque procedures for mounting bolts and recoil mechanism components.

Ensure proper track tension is set after installation.

Preventive Maintenance:

Regular Inspection: Monitor for external seal damage, visible grease leakage (indicating seal failure), and abnormal flange wear patterns during routine walk-arounds.

Greasing Schedule: Adhere strictly to machine OEM intervals, typically every 50-100 service hours. Purge until clean grease is visible at the seal exclusion lips.

Failure Modes & Total Cost of Ownership (TCO): The DPW PARTS AS-Heavy Duty design directly addresses common failure modes:

Seal Ingress: Mitigated by the multi-stage seal.

Bushing Seizure: Prevented by superior bushing material and guaranteed lubrication.

Flange Failure: Resisted through material and hardening upgrades.

This results in extended Mean Time Between Failures (MTBF), reduced frequency of replacement, and lower total lifecycle cost per operating hour.

6. Conclusion: The DPW PARTS Value Proposition

The DOOSAN K1051229 DX700 Guide Wheel Assembly by DPW PARTS is not merely a replacement part; it is a re-engineered system solution. By integrating superior metallurgy, a contamination-resistant sealing philosophy, and precision manufacturing, DPW PARTS delivers an AS-Heavy Duty component that provides predictable, extended service life under the most demanding conditions. It represents an optimal balance between initial cost, operational reliability, and total cost of ownership, making it the specified choice for fleet managers and maintenance experts who prioritize equipment uptime and long-term profitability.

DOOSAN Chassis Components

DOOSAN Chassis Components