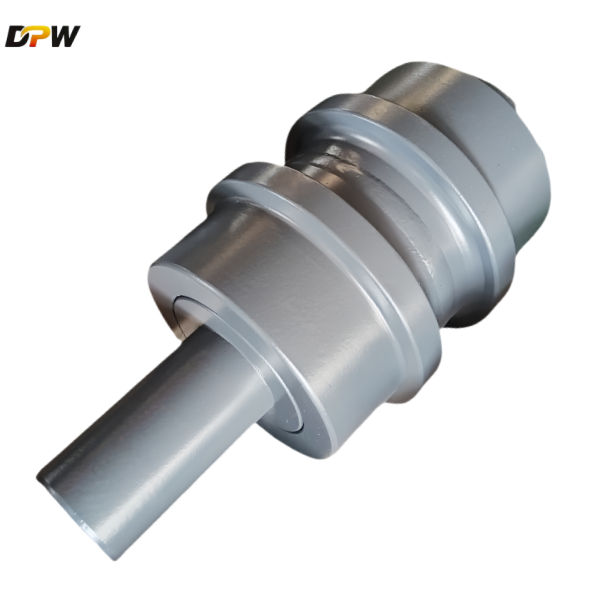

Caterpillar-E385 Carrier Roller Assembly/heavy duty excavator chassis system expert-DPW Machinery Part-supply OEM qualty spare parts

Product Specifications

The Caterpillar E385 Carrier Roller Assembly (also called Top Roller or Upper Roller) is a crucial part of the excavator's undercarriage system. Here's a comprehensive breakdown of its function, importance, replacement signs, and sourcing:

1. Function & Location:

Role: Supports the upper section of the track chain, guiding it in a straight path between the front idler and rear sprocket. Prevents excessive sagging and lateral movement of the top track.

Location: Mounted along the top of the track frame/undercarriage, directly above the bottom track rollers.

2. Key Components:

Outer Shell/Housing: Hardened steel surface contacting the track chain link bushings.

Shaft: Bolted or pressed into the track frame mounting bosses.

Bearings: Sealed, heavy-duty bearings allowing the roller to rotate freely around the fixed shaft.

Seals: Multi-lip seals (critical!) preventing dirt, water, and debris from entering the bearings and retaining lubricating grease. Seal failure is the primary cause of premature carrier roller death.

Flanges (Less Common): Most E385 carrier rollers are flangeless (plain/smooth), as their primary role is support, not lateral guidance (handled by the bottom rollers and idler/sprocket). Confirm the specific design for your machine.

3. Importance & Failure Modes:

Wear: Constant contact with the track chain leads to shell wear. Excessive wear reduces support, causing track slap and accelerated chain/bushing wear.

Seal Failure: Allows contaminants in and grease out. Leads to rapid bearing failure. Check seals regularly for damage, grease leakage, or visible dirt ingress.

Bearing Failure: Causes seized rollers (grinding, no rotation) or excessive wobble/play. Generates heat, noise, vibration, and damages the track chain.

Consequences of Failure: Increased track wear, potential derailment, reduced fuel efficiency, damage to other undercarriage components, costly downtime.

4. Signs Your E385 Carrier Roller Needs Replacement:

Visible Wear/Grooving: Deep scoring or uneven wear on the roller shell.

Lack of Rotation: Roller is seized or rotates stiffly (indicates failed bearings).

Excessive Play/Wobble: Significant movement when prying the roller vertically or laterally.

Grease Leakage: Grease visibly leaking past the seals.

Contaminated Seals: Dirt, mud, or grit packed around the seal area.

Unusual Noises: Grinding, squealing, or rumbling sounds from the top of the undercarriage during operation.

Excessive Track Sag/Vibration: Top track appears overly loose or vibrates noticeably.

5. Model Specifics (E385) & Critical Part Identification:

Variations Exist: Carrier roller assemblies differ based on:

Machine Serial Number (S/N) Prefix: This is ABSOLUTELY ESSENTIAL. Early, mid, and late production E385s may have different roller designs, mounting bolt patterns, or shaft diameters.

Undercarriage Configuration: Standard vs. Long Undercarriage options might influence parts.

Flanged vs. Flangeless: Confirm which type your E385 uses (flangeless is standard for top rollers on most mid-sized Cats, but verify).

Never Guess the Part Number: Using an incorrect carrier roller can lead to poor fitment, rapid failure, and damage to the track frame mounting bosses.

6. Finding the Correct Part Number:

Caterpillar SIS (Service Information System): The definitive source. Requires your E385's full Serial Number.

Caterpillar Dealer: Provide your S/N to your local Cat dealer for the exact Genuine CAT part number, pricing, and availability. They can confirm the assembly (often includes roller, shaft, seals, bearings pre-assembled).

Reputable Aftermarket Suppliers: Companies like Berco, ITR, Prowell, Lemken, FB Mining, and H&L Mesabi offer high-quality compatible carrier rollers. They MUST have your machine's S/N to cross-reference accurately. Quality aftermarket can offer significant savings while meeting OEM specs.

7. Replacement Recommendations:

Use S/N for Identification: This cannot be overstated. It's the key to the correct part.

Genuine CAT vs. Quality Aftermarket: Genuine parts offer OEM assurance. Reputable aftermarket brands provide excellent value and reliability. Avoid unknown cheap brands.

Inspect Seals Religiously: Carrier roller life depends almost entirely on seal integrity. Check them during every undercarriage inspection.

Replace in Pairs/Sets (Best Practice): While you can replace a single failed roller, replacing both carrier rollers on one track side at the same time promotes even wear and optimal track performance/longevity. Consider the condition of all undercarriage components.

Core Exchange: Many suppliers (OEM and aftermarket) offer core exchange programs, giving you credit for returning your old roller assembly.

Professional Installation:

Ensure mounting surfaces on the track frame are clean and undamaged.

Follow precise torque specifications for mounting bolts (critical to prevent shaft rotation or bolt failure).

Handle carefully to avoid damaging seals during installation.

Ensure the roller spins freely after installation.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||