Caterpillar E345/E349 Mining Final Drive Sprocket Rim Assembly/Mining and engineering machinery chassis parts manufacturer-DPW Parts

Product Specifications

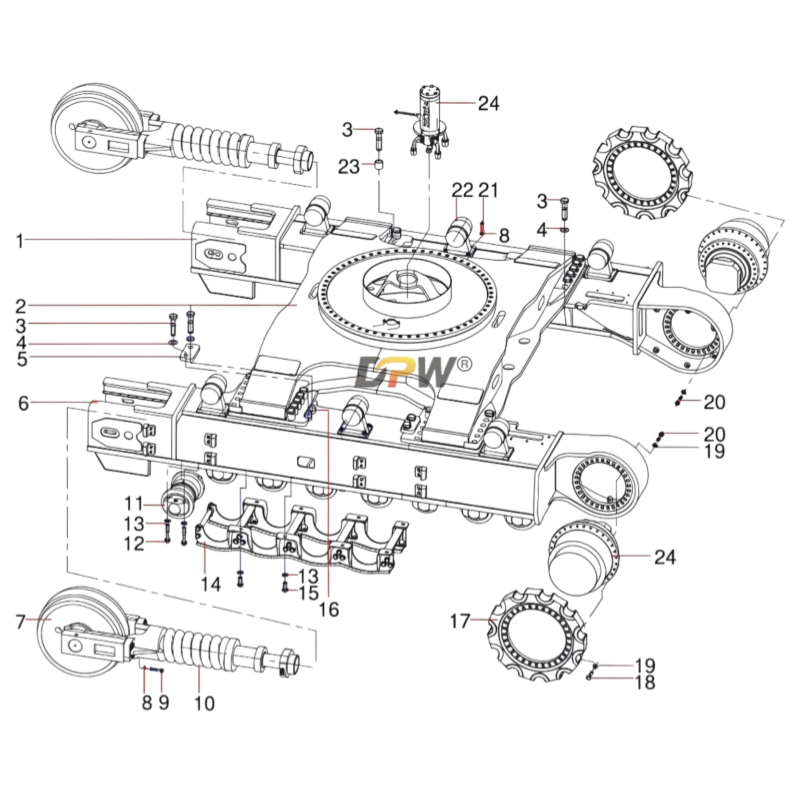

Technical Description: CAT E345 Mining Final Drive Sprocket Wheel Assembly

1. General Overview & Functional Definition

The CAT E345 Mining Final Drive Sprocket Wheel Assembly is an integrated, high-integrity power train component engineered specifically for the demanding "Mining" application of the Caterpillar E345 hydraulic excavator. This assembly is not merely a sprocket; it is a complete system that encapsulates the final stage of gear reduction and the ultimate drive interface with the track chain. dpwparts' sprocket for mining excavators is designed with an even number of teeth in order to provide high resistance to vertical loads.Its primary functions are:

Final Reduction & Torque Multiplication: Houses a multi-stage planetary gearset to convert the high-speed, low-torque input from the hydraulic travel motor into the low-speed, high-torque output required to propel a 45-ton class excavator.

Traction Force Generation: The sprocket teeth directly engage the track chain bushings (pins), pulling the track to generate forward and reverse propulsion.

Structural Integration: Acts as a major structural member of the undercarriage, reacting against immense drive torque, track tension, and machine weight.

Optimized for Severe Service: The "Rock" designation signifies enhanced materials, hardening processes, and sealing systems specifically designed to withstand the high-impact and highly abrasive conditions of rock quarries, mining, and heavy rock excavation.

2. Detailed Component Breakdown & Technical Specifications

This assembly is a pre-engineered, sealed unit where the sprocket and final drive are designed and serviced as a cohesive system.

2.1. Sprocket Wheel (Drive Rim)

Material & Manufacturing: Forged from a proprietary, high-strength, abrasion-resistant alloy steel, such as a chromium-molybdenum (Cr-Mo) variant. Forging ensures optimal grain flow and superior impact resistance compared to casting.

Design Features:

Rock Tooth Profile: The teeth are designed with a specific geometry, often featuring a wider root and a more robust profile than a standard-duty sprocket. This enhances strength and resistance to tooth breakage under high shock loads.

Advanced Hardening Process: The entire tooth profile, including the flanks and critical root area, undergoes a proprietary induction hardening process. This creates a deep, consistent hardened case (typically 6-10 mm) with a very high surface hardness (58-64 HRC) to resist the extreme grinding abrasion from the track bushing in rock.

Integrated Hub Design: The sprocket is typically splined or bolted directly to the output planetary carrier, ensuring a direct and robust connection for transmitting maximum torque.

2.2. Final Drive Gearbox

Planetary Gear Reduction: Utilizes a two or three-stage planetary gear system to achieve the necessary high reduction ratio. This design distributes the load across multiple planet gears, reducing stress on individual components and allowing for a compact form factor.

Gearing: The planetary gears, sun gear, and ring gear are manufactured from case-hardened alloy steels (e.g., 20CrMnTi) to provide a hard, wear-resistant surface and a tough, ductile core.

Final Drive Housing: A high-strength, rigid cast steel or ductile iron housing that contains the gear train and provides the mounting flange to the track roller frame. Its rigidity is critical for maintaining gear alignment under load.

Input Hub: The splined or keyed interface that connects directly to the shaft of the hydraulic travel motor.

2.3. Bearing System

Configuration: Employs a combination of Large-Bore Tapered Roller Bearings and Cylindrical Roller Bearings.

Function:

Tapered Roller Bearings: Specifically chosen to handle the combined radial loads (machine weight) and substantial axial (thrust) loads generated during aggressive turning and track tension.

High Dynamic Load Rating: All bearings are selected for an ultra-high dynamic load capacity to ensure a long service life under continuous severe-duty cycles.

2.4. Severe-Duty Sealing System

Configuration: A multi-layered, robust sealing system is paramount for rock applications. Caterpillar typically employs a Duo-Cone Seal System as the primary defense.

Duo-Cone Seals: These consist of two precision-finished, spring-loaded metal rings with sealing faces. They are highly effective at excluding fine, abrasive rock dust and slurry, and can tolerate minor shaft misalignment and wear.

Labyrinth and Scraper Pre-Seals: External labyrinth paths and rubber scraper seals work in tandem to keep large debris and rocks away from the primary Duo-Cone seals.

Breather System: An integrated breather prevents pressure buildup from thermal expansion and ingression of water through pressure differentials.

2.5. Lubrication System

The gearbox is filled with a specific grade of Cat TDTO (Transmission and Drive Train Oil) or an equivalent certified Extreme Pressure (EP) gear oil. This oil provides lubrication for the gears and bearings, dissipates the significant heat generated, and offers anti-wear and anti-foaming properties.

3. Integration within the E345 Undercarriage System

The Final Drive Sprocket Assembly is the terminal point of the machine's propulsion system:

Interface with Hydraulic System: It is bolted directly to the Cat Travel Motor.

Interface with Track Frame: It is flange-mounted to the rear of the Track Roller Frame, providing critical structural support.

Interface with Track Chain: It drives the specially designed "Rock" Track Chain, which features hardened and/or sealed bushings to match the severe-service sprocket.

4. Critical Performance & Maintenance Parameters

Matched-Wear Concept (Critical): This is a cornerstone of Caterpillar's undercarriage management. The sprocket and track chain must wear together. Installing a new sprocket on a worn chain (or vice versa) will cause accelerated, destructive wear due to pitch mismatch, leading to premature failure of both components.

Sprocket Wear Monitoring: Regularly measure sprocket tooth wear. Cat provides specific wear gauges and limits. "Hooked" or sharply pointed teeth indicate excessive wear and signal the need for replacement to prevent chain damage.

Oil Analysis and Level Checks: Periodic oil sampling and analysis can detect early signs of internal wear (metal particles) or contamination (silicon from dust, water). Maintaining the correct oil level is non-negotiable.

Seal Inspection: Regularly inspect for oil leaks around the sprocket hub and input shaft. A leaking Duo-Cone seal will lead to rapid gear failure and potential track chain contamination.

5. Failure Mode and Effects Analysis (FMEA)

Accelerated/Uneven Tooth Wear: Caused by mismatched track chain, improper track tension, or an misaligned undercarriage.

Tooth Chipping or Fracture: Resulting from extreme impact loads or material fatigue.

Bearing Spalling or Seizure: Often a consequence of seal failure, lubricant loss, or contamination.

Gear Pitting: A surface fatigue failure due to repeated high-contact stresses over time.

Input Shaft Seal Failure: Leads to oil loss and contamination ingress.