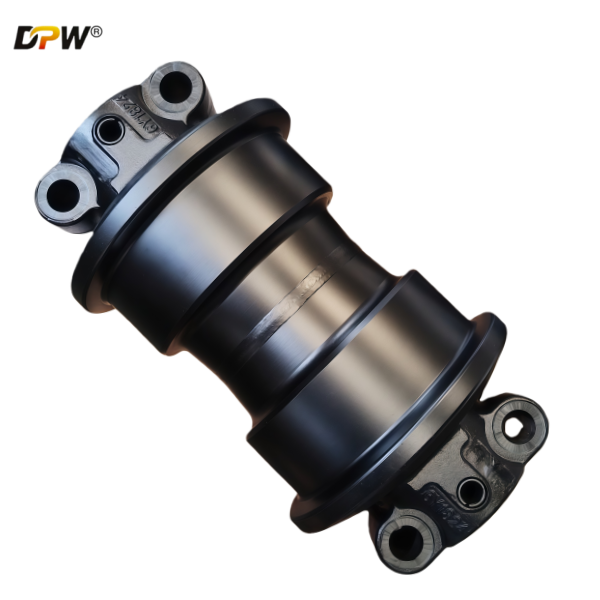

Caterpillar 6Y1824/5297106 E375/E385/E390/E395 Track Support Roller (Track Roller Assembly)Manufactured by DPW Parts

Product Specifications

Product Overview

Product Overview

DPW Parts presents a premium-grade Track Support Roller Assembly, engineered as a direct and reliable replacement for Caterpillar E300-series large excavators. This assembly (compatible with OEM part numbers 6Y-1824 and 5297106) is manufactured to meet the rigorous demands of heavy-duty applications, ensuring optimal undercarriage performance, extended service life, and reduced total cost of ownership. It is the ideal solution for mining, heavy construction, and major earthmoving projects.

Key Features & Engineering Advantages

Direct OEM Fit & Interchangeability

Precision-engineered to match the original dimensions and specifications of Caterpillar parts 6Y-1824 and 5297106.

Guarantees seamless installation and perfect performance on Caterpillar E375, E385, E390, and E395 excavators.

Superior Forged Steel Construction

Manufactured from high-carbon, forged steel for exceptional structural integrity and impact resistance.

The forging process ensures a continuous grain flow, providing superior toughness compared to cast alternatives, effectively withstanding shock loads and preventing cracking.

Advanced Sealing System for Maximum Durability

Features a multi-labyrinth seal design combined with high-quality, heat-resistant lip seals.

Effectively retains grease and excludes abrasive contaminants like dust, mud, and water, significantly extending bearing life and maintenance intervals.

Optimized Heat Treatment Process

The roller tread and flanges undergo controlled induction hardening to achieve a high surface hardness (55-62 HRC), providing exceptional resistance to abrasive wear.

The core remains tough and ductile to absorb heavy impact loads without failure.

High-Capacity Tapered Roller Bearings

Equipped with premium-grade tapered roller bearings designed to handle the extreme radial loads of large excavators.

Ensures smooth rotation under load, reducing friction and power loss.

Technical Specifications

OEM Part Numbers: 6Y-1824, 5297106

Compatible Models: Caterpillar E375, E385, E390, E395 Excavators

Type: Track Support Roller / Lower Roller Assembly

Manufacturing Process: Forging & Precision Machining

Primary Material: High-Carbon Alloy Steel

Applications

This track roller is ideal for the most demanding environments, including:

Surface Mining Operations

Large-Scale Quarry and Aggregate Production

Major Infrastructure and Construction Projects

Heavy-Duty Trenching and Excavation

Quality Assurance

Every DPW Parts Track Roller Assembly undergoes a stringent quality control process, including:

Dimensional Accuracy Verification

Surface Hardness Testing (Rockwell C-Scale)

Seal Performance and Pressure Tests

Visual and Non-Destructive Inspection

Why Choose DPW Parts?

Proven Durability: Our components are built to last, reducing machine downtime and frequency of replacement.

Cost-Effective Solution: Achieve OEM-level performance and longevity at a competitive price, lowering your operating costs.

Engineering Expertise: We specialize in undercarriage components, leveraging advanced manufacturing and metallurgical knowledge.

Global Support: We support a worldwide clientele with reliable logistics and technical assistance.

Call to Action Section (for product page)

Ready to Enhance Your Equipment's Performance?

Request a Custom Quote: [Click Here] to contact our sales team for competitive pricing.

Inquire About Bulk Orders: We offer attractive discounts for high-volume purchases.

Download the Spec Sheet: Get the detailed technical data sheet for your records.

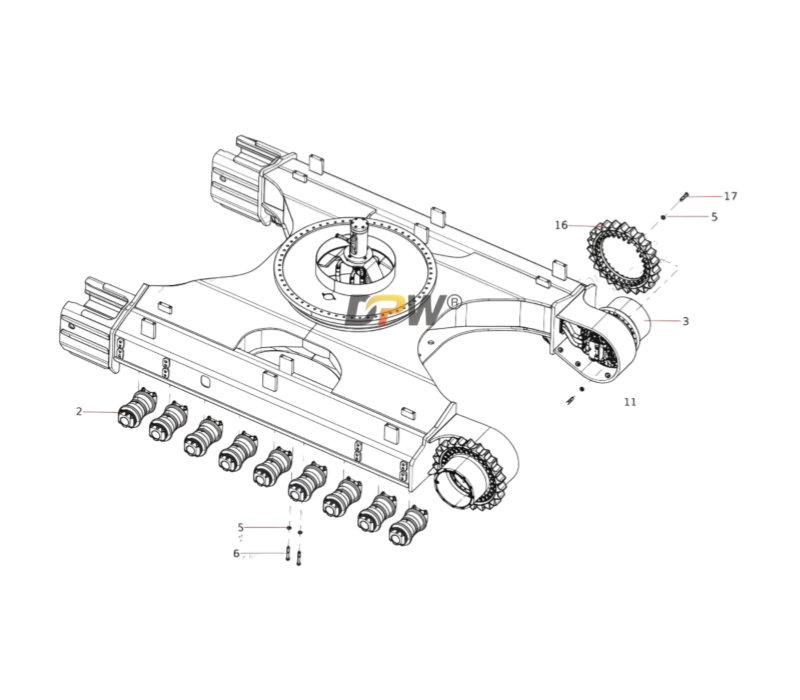

Compatible with: Don't forget to check our other compatible undercarriage components: Track Chains, Sprockets, Idlers, and Carrier Rollers for a complete undercarriage solution.