CAT-E330/517-1248/Kobelco SK350 Track Shoe Assy/Heavy duty chassis components manufacture-DPW parts

Product Specifications

Application: Link to CAT-E330

The "CAT-E330" in the query refers to the machine model. The Caterpillar 330 is a series of 30-40 ton class hydraulic excavators (e.g., 330, 330B, 330C, 330D, 330E, etc.). It is crucial to understand that not every 330 model uses this exact shoe.

Part number 517-1248 is a verified fit for specific serial number ranges of the following models (and their L, LC variants):

330

330B

330C

SK330-8

SK350

Critical Note: For later models like the 330D, 330E, and beyond, the undercarriage specifications may have changed. Always confirm the correct part number using the machine's Product Identification Number (PIN) or serial number on the official Caterpillar parts website or with a CAT dealer. Using an incorrect shoe can lead to severe undercarriage damage.

3. Technical Specifications & Description

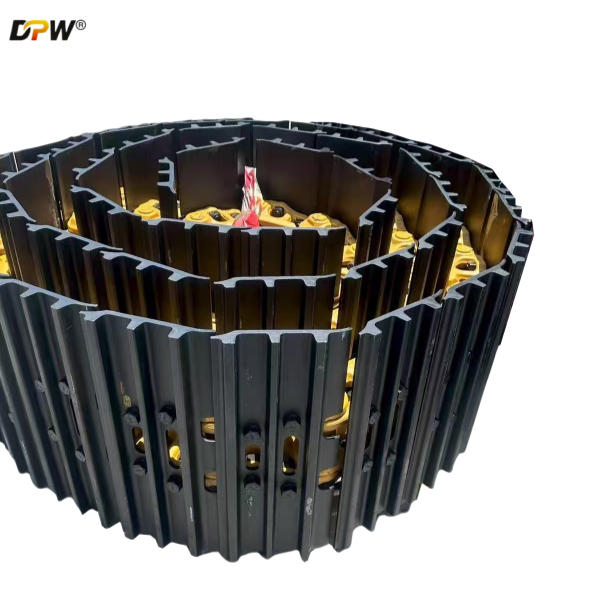

A "Track Shoe Assy" typically refers to a complete segment of the track chain, which includes more than just the ground-engaging plate.

Components of the 517-1248 Assembly:

Track Shoe: The main steel plate that contacts the ground. It features grousers (lugs) for traction.

Link (or Chain): The inner component that the track rollers ride against and the sprocket engages with. The link has a built-in guide (center ridge) to keep the track aligned on the rollers.

Bushings: Pressed into each end of the link. These are the hardened components that the sprocket teeth actually mesh with.

Track Pin & Sleeve (Bushing): The pin connects multiple assemblies together to form a complete track. The sleeve acts as the inner race for the pin, allowing the track to flex.

Key Specifications for 517-1248:

Shoe Width: This is a 700 mm (28") wide shoe.

Grouser Type: It is a double-bar (2-grouser) shoe.

Link Pitch: The distance between the center of one bushing to the next. For this assembly, it is the standard 216 mm pitch common to this size class.

Bolt Pattern: The pattern of bolts that secure the shoe to the link is specific to this part number and designed to match the corresponding link.

Material & Construction: As a genuine CAT part, it is manufactured from high-strength, abrasion-resistant steel. The bushings and pins are case-hardened for exceptional wear resistance and durability.

4. Function and Operational Context

Primary Function: To provide a continuous, durable, and tractive surface for the machine to travel on. It transfers the machine's weight and powerful forces to the ground.

Application: A 700 mm (28") wide shoe is considered a WIDE shoe. It is specifically designed for:

Low Ground Pressure: Distributing the machine's weight over a larger area to prevent it from sinking in soft, unstable, or muddy terrain.

Applications: Ideal for working in clay, silt, sand, saturated soil, and other low-bearing-capacity conditions.

Trade-off: While excellent for soft ground, wider shoes can be more susceptible to wear and damage in rocky or abrasive conditions due to increased twisting leverage. They also provide less penetration force for digging in very hard ground compared to a narrower shoe.

5. When to Replace / Indicators of Wear

This assembly is a wear item. Replacement is necessary when components are worn beyond specified limits:

Worn Grousers: The height of the lugs is significantly reduced, leading to a loss of traction.

Link Wear: The surface where the rollers contact the link becomes thin and sharp ("knife-edged"). The guide height is worn down.

Bushing Wear: The outside diameter of the bushing is worn, affecting sprocket engagement and leading to premature sprocket wear.

Cracks or Breaks: Especially in the shoe itself or around the bolt holes.

Elongated Chain: Overall stretch of the chain due to pin and bushing wear, causing poor track tension and "ratcheting" off the sprocket.

6. OEM vs. Aftermarket Consideration

OEM (517-1248):

Advantages: Guaranteed fit, form, and function. Designed and manufactured to Caterpillar's precise engineering specifications for optimal performance and service life. Full warranty support.

Disadvantages: Higher initial cost.

Aftermarket (Compatible Replacements):

Advantages: Lower initial cost. Many reputable brands (e.g., ITR, Kenco) offer high-quality alternatives.

Disadvantages: Quality can vary dramatically between suppliers. Inferior materials or heat treatment can lead to significantly reduced service life, potentially causing collateral damage to other undercarriage components (rollers, idlers, sprockets).