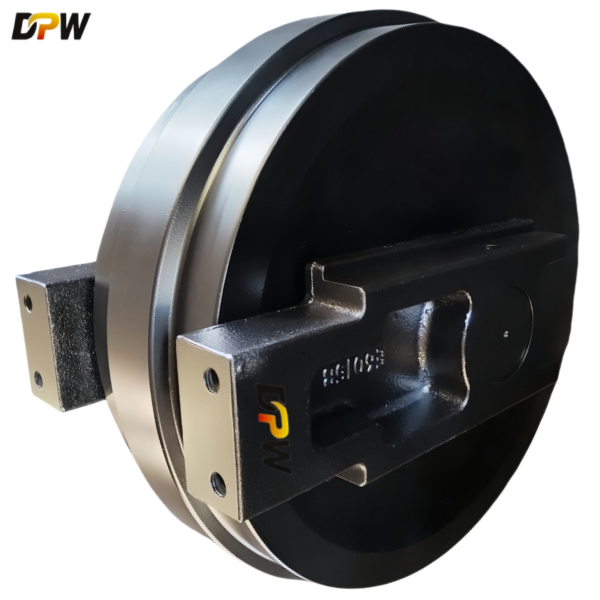

CAT-/4304193/E6015B Front Idler Assembly/Heavy duty crawler excavator undercarriage components manufacture and supplier factory in China

Product Specifications

DPW Construction Machinery Parts supply CAT-E6015B Front Idler Group is a critical undercarriage component for the Heavy-duty Construction Machine Caterpillar E6015B Hydraulic Excavator. Here's a detailed breakdown:

1. Function

Track Guidance: Maintains track alignment and prevents derailment.

Tension Adjustment: Allows fine-tuning of track tension (via adjustment mechanisms).

Load Distribution: Supports excavator weight and absorbs ground impacts.

2. Key Components

Idler Wheel: The front wheel guiding the track.

Mounting Brackets/Frames: Attaches the idler to the excavator’s main frame.

Bushings & Seals: Reduce friction and retain lubrication.

Adjustment Assembly: Includes bolts, nuts, and springs for tension control.

Wear Parts: Flanges, sleeves, and spacers (replaceable during maintenance).

3. Compatibility

Designed specifically for the Caterpillar E6015B excavator model.

Verify your machine’s serial number before ordering—sub-models may have variations.

4. Common Issues

Wear/Flange Damage: From abrasive terrain or misalignment.

Bushing Failure: Causes wobbling or uneven track wear.

Seal Leaks: Leads to contamination and premature wear.

Misadjustment: Results in track slippage or excessive vibration.

5. Replacement & Maintenance Tips

Inspect Regularly: Check for cracks, wear, and seal integrity.

Lubricate: Follow CAT guidelines for greasing intervals.

Track Tension: Adjust per operating manual specs (typically 1–1.5" sag between idler/sprocket).

Use Genuine/OEM Parts: Ensures compatibility and longevity.

6. Part Number Verification

Official CAT Part #:

E6015Bis the machine model, not the part number.Example idler group part numbers:

430-4193 (Group) or4304193(Idler Wheel Assembly) – confirm via your serial number.

Cross-Reference: Use your machine’s S/N on the www.hangongmachinery.com portal or consult a dealer.

7. Where to Buy

Caterpillar Dealers: For genuine parts (e.g., Thompson Machinery, Finning).

Trusted Aftermarket Suppliers: DPW, CQC (ensure quality certification).

8. Safety Note

Always block the excavator securely and relieve track tension before servicing the idler. Hydraulic pressure can cause injury if not properly discharged.

For exact pricing or part numbers, share your excavator’s serial number or contact your local CAT dealer. If troubleshooting issues, describe symptoms

- Hydraulic Mining Shovel caterpillar CAT6015 Track links assy CAT6015 track chains

- Hydraulic Mining Shovel caterpillar CAT6015 Track group CAT6015 track shoes assy 47L 700MM 430-4199

- Hydraulic Mining Shovel caterpillar CAT6015 Track shoes

- Hydraulic Mining Shovel caterpillar CAT6015 Track rollers 2307162 CAT6015 bottom rollers 230-7162 CAT6015 lower rollers

- Hydraulic Mining Shovel caterpillar CAT6015 Carrier rollers 4304195 CAT6015 upper rollers 430-4195 CAT6015 top rollers

- Hydraulic Mining Shovel caterpillar CAT6015 sprocket

- Hydraulic Mining Shovel caterpillar CAT6015 Sprocket bolts 7X-2586

- Hydraulic Mining Shovel caterpillar CAT6015 track bolts

- Hydraulic Mining Shovel caterpillar CAT6015 track nuts

- Hydraulic Mining Shovel caterpillar CAT6015 Bucket Adapter 572-0861 5720861 Weld-On M75 Two Strap Adapter repair China suppliers

- Hydraulic Mining Shovel caterpillar CAT6015 Bucket Adapter 572-0862 5720862 Weld-On M75 Two Strap Straddle Adapter – LH China suppliers

- Hydraulic Mining Shovel caterpillar CAT6015 Bucket Adapter 572-0863 5720863 Weld-On M75 Two Strap Straddle Adapter – RH aftermarket China suppliers