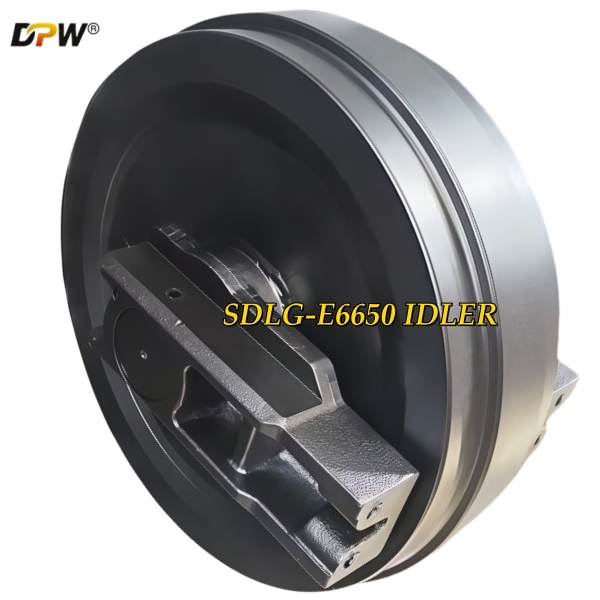

SDLG E6650 Front Idler Assembly /Track Guide Wheel/Manufactured by DPW Machinery Parts

Product Specifications

Meta Description: Detailed technical analysis of the DPW aftermarket Front Idler Assembly (Track Guide Wheel Assy) for the SDLG E6650 excavator. Explore its engineered structure, component materials, sealing technology, and performance benefits as a durable, cost-effective undercarriage solution.

1. Component Overview and Functional Definition

The Front Idler Assembly, also commonly referred to as the Track Guide Wheel Assembly, is a pivotal component in the undercarriage system of a crawler excavator. The SDLG E6650 model, as manufactured by DPW Machinery Parts, is an aftermarket replacement designed to match or exceed original equipment specifications.

Its primary functions are:

Track Guidance and Tensioning: It serves as the front guiding point for the track chain, ensuring proper alignment. It is part of the track tensioning system, allowing for adjustment to maintain optimal track tightness and prevent derailment.

Load Distribution and Impact Absorption: It helps to support the machine's weight and absorbs significant impact loads when the track rolls over obstacles and during directional changes.

Track Contour Formation: It guides the track into the correct "D" or "triangular" shape, working in concert with the sprocket and lower rollers to ensure smooth and efficient travel.

2. Detailed Mechanical Structure and Component Breakdown

This DPW assembly is a robust, pre-assembled unit built for durability in demanding conditions. Its construction can be broken down into the following critical sub-components:

2.1. Idler Wheel Body

Material: Fabricated from high-strength, Casted Alloy Steel (e.g., 40Mn2, 50Mn), chosen for its superior impact toughness and fatigue resistance compared to cast iron or lower-grade steels.

Manufacturing Process: The outer rim undergoes precision machining and is typically induction hardened to a significant depth (e.g., 5-8 mm). This creates a surface hardness of 55-60 HRC to resist the abrasive wear from the track chain bushings, while the core remains ductile to withstand shock loads.

Design Feature: The wheel features a central guide flange that runs in the gap between the track links. This flange is critical for maintaining track alignment and is specially reinforced to handle lateral forces during turning.

2.2. Idler Bushing (Sleeve) and Shaft

Bushing/Sleeve: A hardened and ground steel bushing is often pressed into the idler wheel's center. This bushing acts as the inner race for the bearing system and is a sacrificial component, designed to be more easily replaceable than the idler body itself in some designs, though this DPW unit is typically a sealed cartridge.

Shaft (Spindle): This is the stationary axle, manufactured from high-tensile carbon or alloy steel, and heat-treated for high strength. It is the component that mounts directly to the idler bracket and the adjustable tensioning mechanism on the excavator's track frame.

2.3. Bearing System

Type: Utilizes a set of Tapered Roller Bearings. These are selected for their exceptional capacity to handle the combined heavy radial loads from the machine's weight and substantial axial (thrust) loads generated during steering and side-slope operation.

Configuration: The bearings are pre-lubricated, pre-adjusted, and pressed onto the stationary shaft within the idler body, ensuring optimal load distribution and rotational smoothness.

2.4. Multi-Stage Labyrinth Seal System

The longevity of the idler is dictated by its ability to retain grease and exclude contaminants. DPW employs an advanced sealing system:

Primary Seal: A Radial Lip Seal or, more commonly in heavy-duty applications, a Mechanical Face Seal (Floating Seal). This face seal consists of two highly polished, hardened steel (or tungsten carbide) rings that are forced together by O-rings, creating a highly effective dynamic seal.

Secondary Defenses: The seal is housed within a Labyrinth style structure, creating a tortuous path that hinders the ingress of mud, water, and abrasive particles. External Dust Lips made of nitrile rubber provide a first line of defense against large contaminants.

2.5. Internal Lubrication

The cavity containing the bearings is packed with a high-temperature, high-pressure Lithium Complex EP (Extreme Pressure) Grease. This specialized lubricant is designed to maintain film strength under heavy loads and resist washing out or breaking down under operational heat.

2.6. Tensioning Mechanism Interface

The idler assembly connects to the excavator's track frame via a tensioning cylinder or screw mechanism. The DPW idler is engineered with the correct mounting points and geometry to ensure seamless integration with the SDLG E6650's specific tensioning system.

3. Key Features of the DPW Machinery Parts Manufactured Assembly

OEM Interchangeability: Engineered as a direct replacement for the original SDLG part, ensuring a perfect fit and correct alignment.

Material Integrity: Use of certified forged steel and rigorous heat treatment processes ensures superior impact strength and wear resistance.

Advanced Sealing Technology: The robust seal system is the cornerstone of its extended service life, effectively preventing premature failure in wet and abrasive environments.

Pre-assembled and Pre-lubricated: Supplied as a complete, ready-to-install unit, reducing downtime and eliminating the risk of improper field assembly.

4. Common Failure Modes and Indicators

Flange Wear: Excessive wear on the guide flange leads to poor track alignment and potential derailment.

Bearing/Seal Failure: Evidenced by grease leakage, difficult rotation, grinding noises, and excessive play. This is often the result of seal compromise.

Rim Wear/Spalling: Abrasive wear reduces the idler diameter, while high-impact loads can cause chipping or spalling of the hardened surface.