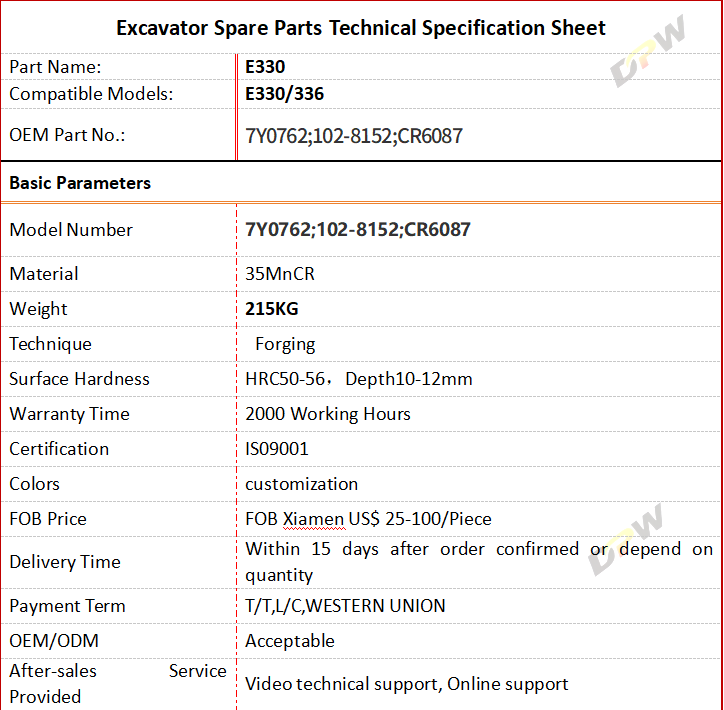

(P/N:7Y0762;102-8152; CR6087)CATERPILLAR E330/336 front track idler GP-track idler ass'y-china idlers factories-idlers repair-forged steel idler factory

Product Specifications

(P/N:7Y0762;102-8152; CR6087)CATERPILLAR E330/336 front track idler GP-track idler ass'y-china idlers factories-idlers repair-forged steel idler factory

E330 Idlers – Heavy-Duty Undercarriage Rollers for 30-Ton Class Excavators

E330 idlers are engineered for 30-40 ton excavators, providing reliable track support in demanding earthmoving, quarrying, and construction applications. These components are crucial for maintaining proper track tension and alignment on machines like the Caterpillar 330, Komatsu PC300, and Hitachi ZX330.

Key Features

✔ Forged Steel Construction – Superior strength and impact resistance compared to cast idlers

✔ Sealed & Lubricated Bearings – Extended service life with minimal maintenance

✔ Precision Machined Surfaces – Smooth operation with reduced track shoe wear

✔ OEM-Compatible Design – Direct replacement for original equipment idlers

Types of E330 Idlers

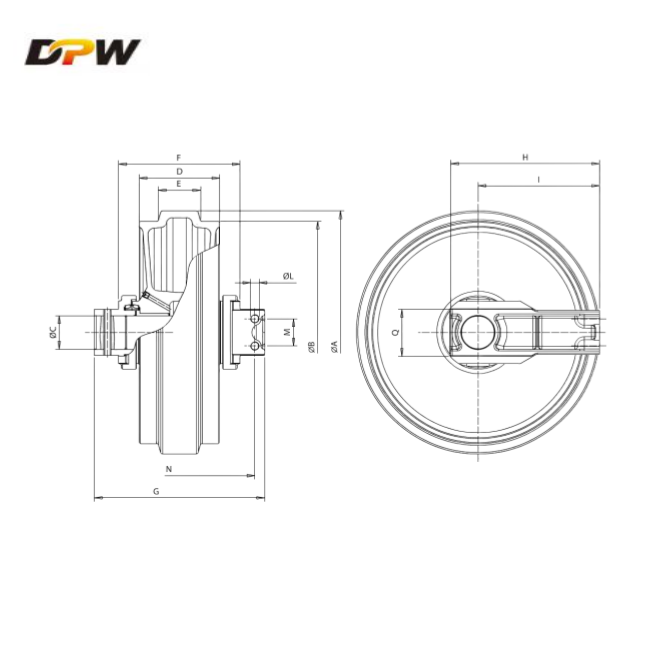

Front Idlers (Guide Idlers)

Maintain track tension and alignment

Available in smooth or grooved designs

Bottom Rollers (Lower Rollers)

Support machine weight and track chain movement

Double-flange design for optimal load distribution

Carrier Rollers (Upper Rollers)

Prevent track sagging on upper frame section

Single or double flange configurations available

Performance Benefits

20% Longer Service Life compared to standard idlers

Reduced Undercarriage Vibration for smoother operation

Interchangeable with major OEM part numbers

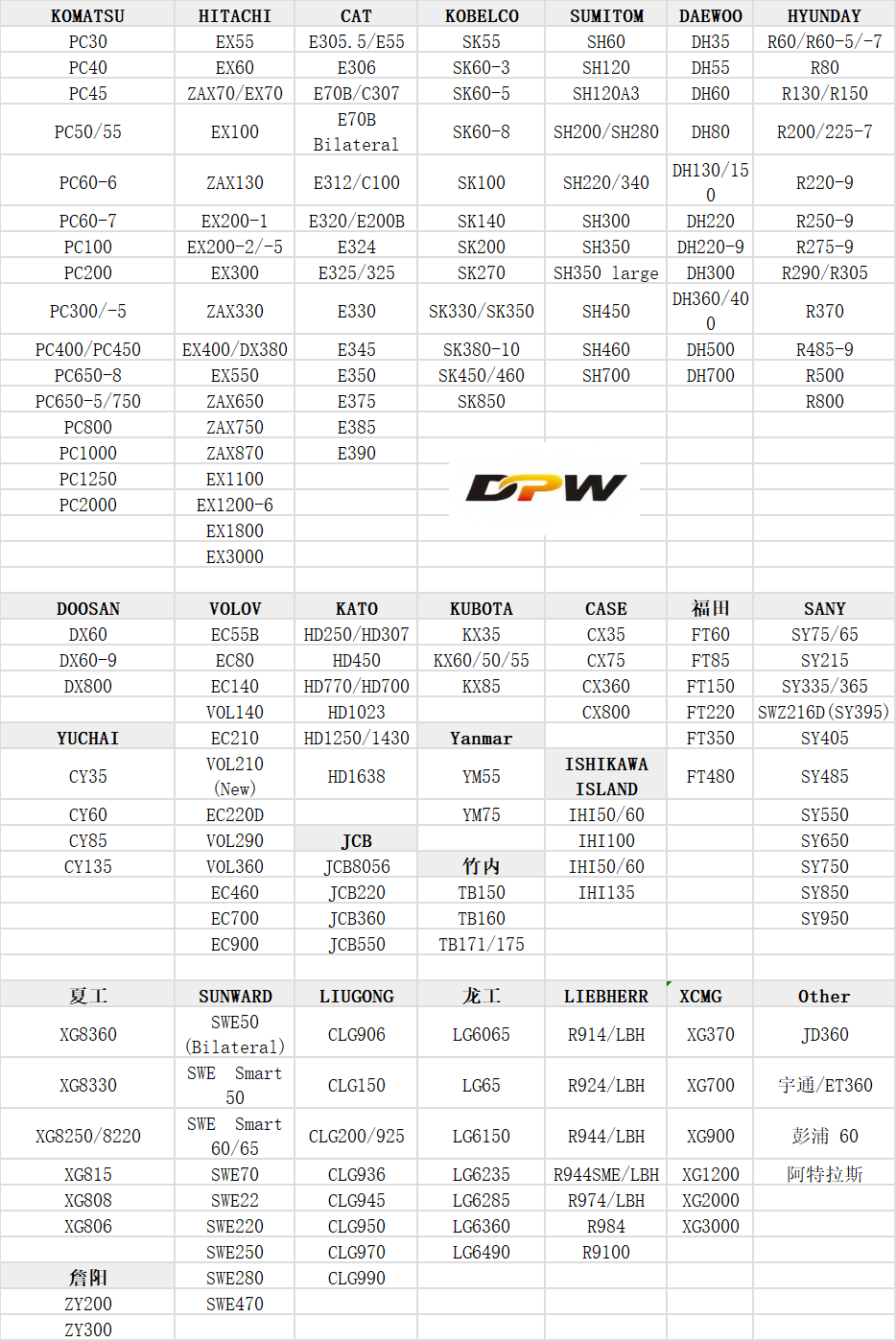

Compatibility

Designed to fit:

Caterpillar 330, 330B, 330C, 330D

Komatsu PC300-6, PC300-7, PC300-8

Hitachi ZX330, ZX330-3, ZX330-5

Volvo EC330, EC340 EC360

When to Replace E330 Idlers?

⚠ Visible flange wear exceeding 30% of original thickness

⚠ Flat spots or irregular wear patterns

⚠ Failed bearings causing roller seizure

⚠ Oil leaks from damaged seals

Maintenance Recommendations

• Clean Regularly – Remove packed mud and debris

• Check Every 500 Hours – Inspect for abnormal wear

• Replace in Sets – For balanced track performance

Pro Tip: For extreme conditions (mining, rock quarries), consider hardened or tungsten-carbide coated idlers for 2X longer lifespan.

Need exact specifications or pricing? Provide:

Your machine model/year

Current idler condition

Primary working environment