VOVOL 14525744 EC650/EC700/EC700BLC forged Idler Wheel Assembly/Heavy duty excavator undercarriages Source manufacture

Product Specifications

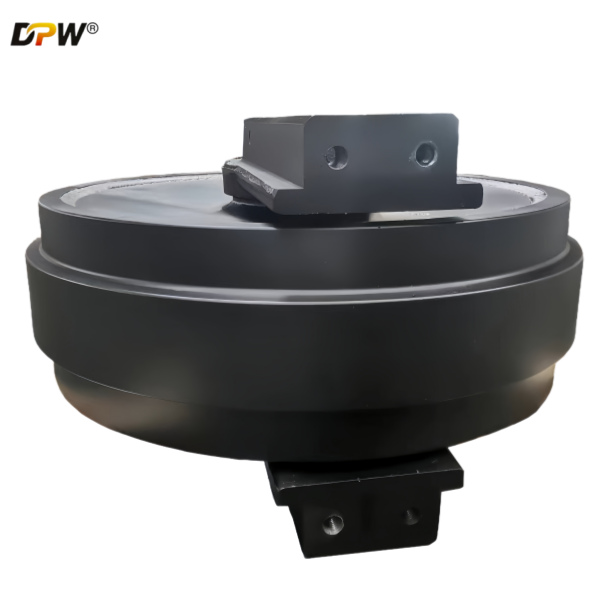

Deconstructing the VOLVO EC700BLC Fabricated Idler Assembly: A Structural and Functional Analysis

The VOLVO EC700BLC Fabricated Idler Assembly is a masterclass in heavy-duty undercarriage engineering, designed specifically for the rigorous demands of a 70-ton-class crawler excavator. This critical component is far more than a simple guide wheel; it is a complex, integrated system central to track guidance, tensioning, and overall machine stability. A deep dive into its structure reveals the meticulous design philosophy behind Volvo's robust equipment.

1. Core Functional Principle

Acting as the forward-most component on the track frame, the Fabricated Idler Assembly serves three primary functions:

Track Guidance: To provide a smooth, contoured surface for the track chain to roll upon, ensuring proper alignment and preventing derailment.

Track Tensioning: To act as the adjustable anchor point for the track tensioning system, allowing for precise control of track tightness via a hydraulic or grease-powered mechanism.

Load Distribution & Impact Absorption: To help support the machine's weight and absorb dynamic shocks from traversing uneven terrain and obstacles.

2. Comprehensive Structural Breakdown

The term "Fabricated" is key to its construction, indicating it is built up from high-strength steel plates welded together, as opposed to being a single casting. This method allows for optimized strength-to-weight ratios and superior durability. The assembly can be dissected into the following key subsystems:

A. The Idler Wheel (Fabricated Core)

Material: Fabricated from Q345B or equivalent high-yield strength steel plate, chosen for its excellent impact toughness and wear resistance.

Construction: The wheel is not a solid disc. It consists of two precision-rolled side discs welded to a central hub. This creates a hollow, box-like structure that is exceptionally rigid yet manages weight effectively.

Running Surface (Tire): The outer circumference is machined to a specific profile. This includes a central track chain race where the track link bushings (the "pins") contact and roll, and two integral flanges on either side. These flanges are critical for preventing lateral track drift and derailment.

Heat Treatment: The running surface often undergoes flame hardening or induction hardening to achieve a high surface hardness (typically 55-60 HRC), significantly extending service life by resisting wear from the hardened track bushings.

B. The Bearing & Sealing System (The Rotational Heart)

Housed within the idler wheel is a robust system enabling smooth rotation while excluding contaminants.

Bearing Type: Utilizes a pair of large-bore, tapered roller bearings. This bearing type is selected for its ability to handle significant radial loads (from the machine's weight) and substantial axial thrust loads (generated during steering and side-slope operation).

Bearing Housing: The bearings are pressed onto a stationary spindle or shaft, which is then bolted rigidly to the idler bracket. The wheel rotates around this fixed spindle.

Sealing System: A multi-stage, labyrinth-style seal is employed, often with multiple radial lip seals and grease-filled chambers. This creates a complex path that prevents the ingress of abrasive contaminants like silica dust, slurry, and water. An external end cap provides the final physical barrier.

C. The Idler Bracket or Carrier (The Structural Anchor)

This is the foundational structure that connects the entire idler assembly to the excavator's track frame.

Fabricated Design: Like the wheel, the bracket is a welded fabrication from thick steel plates, forming a rigid, box-section housing.

Function: It serves as the mount for the spindle and incorporates the tensioning cylinder interface. This is a critical load path, transferring all operational forces from the idler into the main track frame.

Tensioning Mechanism Interface: The bracket features a socket or clevis that connects to the track tensioning cylinder. This cylinder, when pressurized with grease, pushes the entire idler assembly forward to increase track tension.

D. The Tensioning Cylinder (The Adjustment Mechanism)

While sometimes considered a separate part, it is integral to the assembly's function.

Design: A hydraulic (grease) piston housed within a cylinder tube.

Operation: Grease is pumped into the cylinder via a zerk fitting, extending the piston, which in turn pushes against the idler bracket to adjust track tension. A check valve retains the pressure to maintain the set tension.

3. Material Science and Manufacturing Integrity

Welding Standards: All welds are performed to high standards, often using Submerged Arc Welding (SAW) for critical joints to ensure deep penetration and high integrity.

Corrosion Protection: Components are typically shot-blasted to remove mill scale and create an optimal surface profile before the application of a high-performance epoxy primer or being hot-dip galvanized for severe environments.

4. Failure Mode Analysis and Design Countermeasures

The design directly addresses common points of undercarriage failure:

Countermeasure for Bearing Failure: The advanced labyrinth seal system drastically extends bearing life by excluding abrasives.

Countermeasure for Flange Wear: The hardened running surface and robust flange design resist deformation and wear from track contact.

Countermeasure for Structural Fatigue: The fabricated, box-section design provides superior resistance to bending and torsional stresses compared to older cast designs.

Conclusion: An Engineered System for Peak Performance

The VOLVO EC700 Fabricated Idler Assembly is a precision-engineered system where every structural element—from the fabricated steel plates and hardened running surface to the tapered roller bearings and multi-stage seals—is optimized for durability, performance, and reliability. Its design is a direct response to the extreme loads and harsh environments encountered in mining, heavy construction, and quarrying, ensuring the Volvo EC700 excavator maintains optimal traction, stability, and productivity throughout its service life.