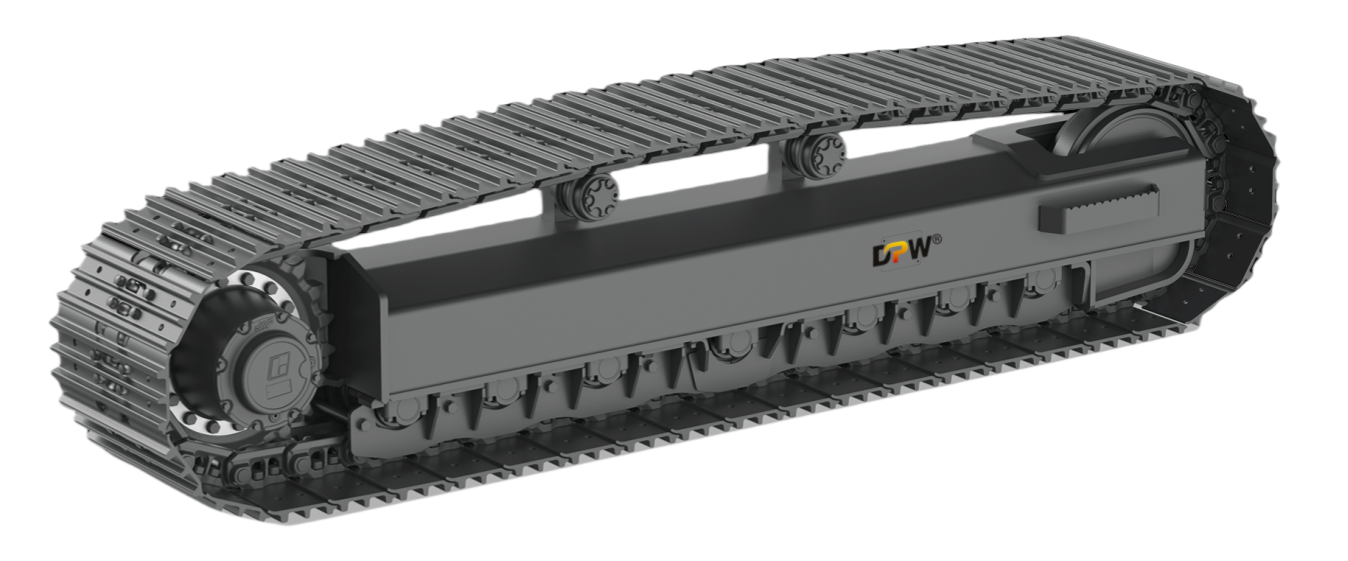

VOLVO-EC360 Final Drive Sprocket Assembly/Heavy-duty excavator undercarriage components manufacture and supplier offered directly

Product Specifications

Comprehensive Technical Guide: Volvo EC360 Final Drive Sprocket Assembly Structure

1. Core Definition & Functional Role

The Volvo EC360 Final Drive Sprocket Assembly is a precision-engineered undercarriage component that transmits torque from the final drive gearbox to the excavator’s tracks. It serves as the critical interface between hydraulic power and mechanical movement, enabling controlled propulsion, climbing, and heavy-load operations.

2. Structural Components Breakdown

① Drive Sprocket Wheel

Material: Forged alloy steel (ISO 683-1 standard), hardened to 58-62 HRC for wear resistance.

Tooth Design: 10–12 involute-profile teeth optimized for seamless engagement with track chain links.

Hardening Process: Induction-hardened tooth flanks (1.5–2.0 mm depth) to withstand abrasive wear.

Material: Forged alloy steel (ISO 683-1 standard), hardened to 58-62 HRC for wear resistance.

Tooth Design: 10–12 involute-profile teeth optimized for seamless engagement with track chain links.

Hardening Process: Induction-hardened tooth flanks (1.5–2.0 mm depth) to withstand abrasive wear.

② Hub Assembly

Central Hub: Machined from SAE 4140 steel with tapered bore (1:10 taper) for precise mounting on the final drive output shaft.

Mounting Flange: Integrates 8–12 x M24 high-tensile bolts (ISO 898-1 Class 10.9) for rigid coupling to the final drive.

Anti-Wear Collar: Replaceable steel ring protecting the hub from track link abrasion.

Central Hub: Machined from SAE 4140 steel with tapered bore (1:10 taper) for precise mounting on the final drive output shaft.

Mounting Flange: Integrates 8–12 x M24 high-tensile bolts (ISO 898-1 Class 10.9) for rigid coupling to the final drive.

Anti-Wear Collar: Replaceable steel ring protecting the hub from track link abrasion.

③ Bearing & Seal System

Tapered Roller Bearings: Dual Timken®-type bearings (e.g., 32326-XL/J2) handling radial/axial loads.

Labyrinth Seals: Triple-path seal design with Nitrile lip seals (NBR) preventing ingress of mud, water, and debris.

Grease Cavities: Zerk fittings for periodic lubrication (recommended: NLGI #2 lithium-complex grease).

Tapered Roller Bearings: Dual Timken®-type bearings (e.g., 32326-XL/J2) handling radial/axial loads.

Labyrinth Seals: Triple-path seal design with Nitrile lip seals (NBR) preventing ingress of mud, water, and debris.

Grease Cavities: Zerk fittings for periodic lubrication (recommended: NLGI #2 lithium-complex grease).

④ Bolt Circle & Fastening

Bolt Pattern: 8–12-hole ISO flange with pre-tensioned bolts torqued to 450–500 N·m.

Locking Mechanism: Nord-Lock washers or thread-locking compound (Loctite® 271) preventing vibration loosening.

Bolt Pattern: 8–12-hole ISO flange with pre-tensioned bolts torqued to 450–500 N·m.

Locking Mechanism: Nord-Lock washers or thread-locking compound (Loctite® 271) preventing vibration loosening.

⑤ Wear-Indicator Features

Tooth Height Markings: Laser-etched wear limits (replace at <70% original height).

Flange Alignment Notches: Visual indicators for sprocket-to-track alignment checks.

Tooth Height Markings: Laser-etched wear limits (replace at <70% original height).

Flange Alignment Notches: Visual indicators for sprocket-to-track alignment checks.

3. Material Science & Engineering Specifications

Parameter Specification Sprocket Material 42CrMo4 steel (EN 10083) Surface Treatment QPQ (Quench-Polish-Quench) salt bath nitriding Hardness Core: 28–32 HRC; Teeth: 58–62 HRC Weight 95–110 kg (EC360B/BLC models) Bolt Torque 450–500 N·m (dry torque)

| Parameter | Specification |

|---|---|

| Sprocket Material | 42CrMo4 steel (EN 10083) |

| Surface Treatment | QPQ (Quench-Polish-Quench) salt bath nitriding |

| Hardness | Core: 28–32 HRC; Teeth: 58–62 HRC |

| Weight | 95–110 kg (EC360B/BLC models) |

| Bolt Torque | 450–500 N·m (dry torque) |

4. Failure Modes & Structural Weak Points

Premature Tooth Wear: Caused by track chain elongation >3% beyond spec.

Bolt Shearing: Result of improper torque sequencing or corrosion.

Seal Degradation: Heat cracking from contaminated grease (>120°C operating temp).

Hub Cracking: Fatigue near keyways due to shock loads or misalignment.

Premature Tooth Wear: Caused by track chain elongation >3% beyond spec.

Bolt Shearing: Result of improper torque sequencing or corrosion.

Seal Degradation: Heat cracking from contaminated grease (>120°C operating temp).

Hub Cracking: Fatigue near keyways due to shock loads or misalignment.

5. Compatibility & Model Variations

Volvo Model Part Number Key Distinction EC360B 14520694 10-tooth design, Ø620 mm PCD EC360BLC 108101850 Reinforced hub for LGP track pads EC360C P14520694 Upgraded seal cavity design

| Volvo Model | Part Number | Key Distinction |

|---|---|---|

| EC360B | 14520694 | 10-tooth design, Ø620 mm PCD |

| EC360BLC | 108101850 | Reinforced hub for LGP track pads |

| EC360C | P14520694 | Upgraded seal cavity design |

PCD = Pitch Circle Diameter; LGP = Low Ground Pressure

6. Manufacturing Tolerances (ISO 286)

Hub Bore: H7 tolerance (+0.000/+0.025 mm)

Flange Runout: <0.1 mm TIR (Total Indicator Reading)

Tooth Profile Error: <0.15 mm per tooth

Hub Bore: H7 tolerance (+0.000/+0.025 mm)

Flange Runout: <0.1 mm TIR (Total Indicator Reading)

Tooth Profile Error: <0.15 mm per tooth

7. Maintenance Best Practices

Torque Verification: Re-check bolts after 50 operating hours.

Wear Symmetry Check: Measure tooth height at 3 positions (max variance: 2 mm).

Grease Purge: Flush cavity every 500 hours using high-temperature EP grease.

Track Tension: Maintain 40–50 mm sag (midway between idler/sprocket) to reduce sideload.

Torque Verification: Re-check bolts after 50 operating hours.

Wear Symmetry Check: Measure tooth height at 3 positions (max variance: 2 mm).

Grease Purge: Flush cavity every 500 hours using high-temperature EP grease.

Track Tension: Maintain 40–50 mm sag (midway between idler/sprocket) to reduce sideload.

8. Why Genuine Volvo Sprocket Assembly?

Finite Element Analysis (FEA): Optimized stress distribution under 25-ton+ swing loads.

Microgeometry Optimization: Tooth root radii machined to reduce stress concentration (Kt < 1.8).

Corrosion Protection: Zn-Ni electroplating (8–12 μm) + anti-corrosion wax injection.

⚠️ Critical Note: Aftermarket sprockets often use JIS steel (SCM440) with lower impact toughness (-30% Charpy V-notch value vs. genuine Volvo).

Finite Element Analysis (FEA): Optimized stress distribution under 25-ton+ swing loads.

Microgeometry Optimization: Tooth root radii machined to reduce stress concentration (Kt < 1.8).

Corrosion Protection: Zn-Ni electroplating (8–12 μm) + anti-corrosion wax injection.

⚠️ Critical Note: Aftermarket sprockets often use JIS steel (SCM440) with lower impact toughness (-30% Charpy V-notch value vs. genuine Volvo).