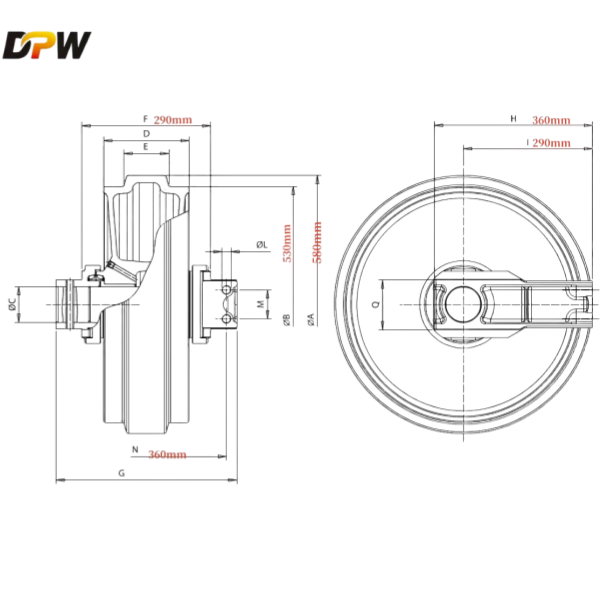

VOLVO EC290 forging front idler wheel assembly(14520281;P9329400M00)/DPW PARTS supply high quality spare part for heavy duty crawler excavator undercarriages

Product Specifications

A fabricated EC290 front idler assembly provides a cost-effective, quick-delivery alternative to OEM parts for Volvo excavators. These custom-built idlers use high-tensile welded steel to match OEM durability while allowing flange-width customization for unique track setups. Whether you need a mine-duty reinforced idler or a fast replacement for a failed unit, our guide compares top suppliers and installation tips to minimize downtime.

1. What is a Fabricated Front Idler Assembly?

A custom-made idler wheel, axle, brackets, and sometimes adjusters, built to replace the original.welding and forging idler wheels

Often used when:

OEM parts are too expensive or unavailable.

Heavy-duty or modified applications require stronger materials.

The machine has been adapted (e.g., for different tracks or undercarriage modifications).

2. Key Components of the Assembly

A complete fabricated front idler assembly for an EC290 typically includes:

Idler Wheel – The main wheel that guides the track.

Material options: Hardened steel, reinforced composite, or alloy.

May include replaceable wear surfaces or bushings.

Shaft/Axle – Supports the idler wheel.

Brackets & Bolts – Attaches the idler to the excavator frame.

Adjustment Mechanism (if applicable) – For track tensioning.

Seals & Bearings – Prevents debris ingress and ensures smooth rotation.

3. Why Choose a Fabricated Idler Over OEM?

| Factor | OEM Idler | Fabricated Idler |

|---|---|---|

| Cost | Expensive | More affordable (if locally made) |

| Availability | Long lead times | Faster (if custom shops are nearby) |

| Durability | Standard specs | Can be reinforced for harsh conditions |

| Customization | Fixed design | Adjustable for modified setups |

4. Common Issues with Fabricated Idlers

Misalignment → Causes uneven track wear.

Weak Welds → Can crack under stress.

Poor Bearing Fit → Leads to premature failure.

Incorrect Hardness → May wear out faster than OEM.

Solutions:

✔ Use high-tensile steel and precision machining.

✔ Ensure proper track tension to avoid side loading.

✔ Install quality bearings & seals (e.g., SKF or NSK).

5. Where to Get a forged Idler Assembly?

Undercarriage Parts Suppliers (DPW Machinery PARTS)

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

A fabricated front idler assembly can be a cost-effective and durable solution for your Volvo excavators, but quality control is critical. If you need help with technical drawings, material specs, or sourcing, let me know—I can guide you further!

Would you like recommendations for specific suppliers or CAD designs?