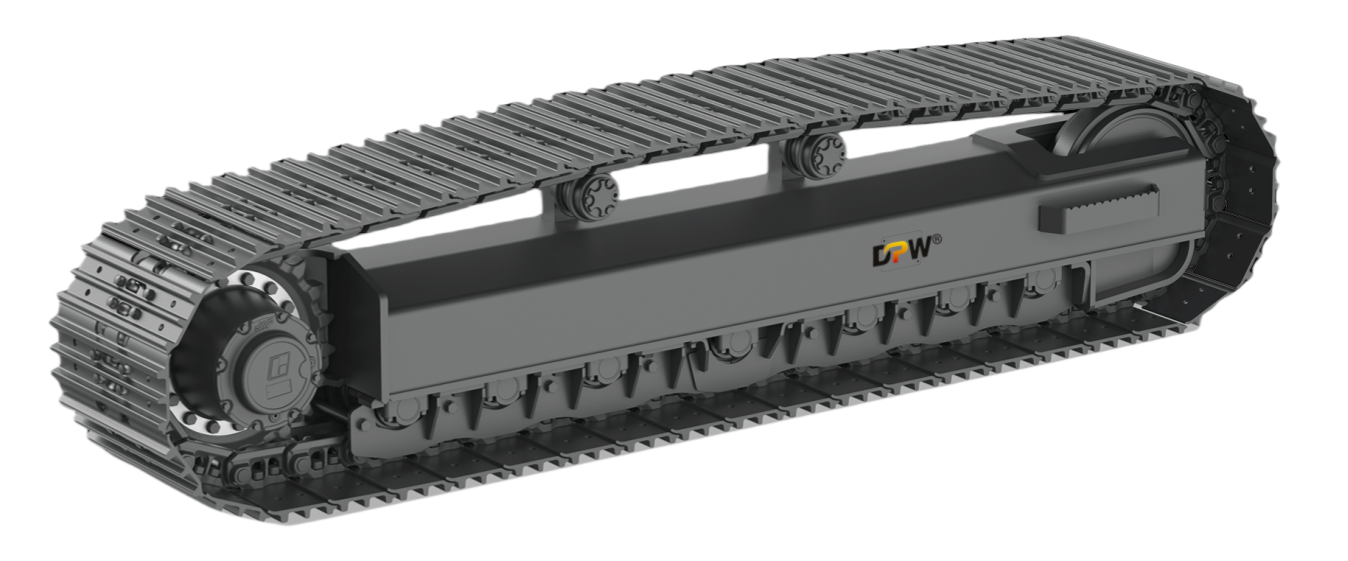

SANY-SY1250 Carrier Roller Assy/DPW PARTS-Heavy duty crawler chassis components manufacture and source factory

Product Specifications

Executive Summary

The SANY-SY1250 Carrier Roller Assy is a crucial undercarriage component designed for SANY SY1250 model excavators. Its primary function is to support the weight of the excavator's upper structure and to guide and maintain the alignment of the track chain along the track frame. Manufactured to endure harsh operating conditions, this assembly is built with high-strength materials and is engineered for durability, reliability, and ease of maintenance, ensuring the stable and efficient operation of the excavator.

1. Overall Function and Importance

The Carrier Roller Assembly, often called a top roller or upper roller, is a key part of the crawler undercarriage system. Its core functions are:

Weight Support: It helps support the immense weight of the machine, working in conjunction with the track rollers and the track chain itself.

Track Guidance: It maintains the correct alignment of the track chain, preventing lateral slippage or derailment during operation, especially when the machine is turning or operating on slopes.

Load Distribution: It contributes to distributing the operational loads across the undercarriage system.

Track Tension Maintenance: It plays a role in maintaining proper track tension in conjunction with the idler and sprocket.

A malfunctioning carrier roller can lead to premature track wear, mis-tracking, increased fuel consumption, and potential damage to other undercarriage components.

2. Main Components and Construction

Based on standard carrier roller assembly designs, the SANY-SY1250 Carrier Roller Assy likely consists of the following key components:

| Component | Description & Function |

|---|---|

| Roller Wheel | The main rotating element that directly contacts the track chain. It is typically manufactured from high-carbon, high-chromium alloy steel for exceptional hardness and wear resistance. The wheel is precisely machined and heat-treated (e.g., through quenching) to achieve a hardened surface, greatly extending its service life under abrasive conditions. |

| Shaft | A high-strength hardened steel shaft that serves as the central axle for the roller wheel. It is designed to withstand significant shear and bending forces. The shaft is securely fixed to the roller frame and does not rotate. |

| Seals | Multi-labyrinth seals are critical for excluding contaminants (like dirt, mud, and water) and retaining lubricant within the housing. Many modern heavy equipment rollers utilize King Pin Seals (KPS) or similar advanced sealing systems that combine radial lips with labyrinth paths, offering superior protection in severe environments. |

| Bearings | Tapered roller bearings or needle bearings are commonly used due to their high radial load-carrying capacity. They facilitate the smooth rotation of the roller wheel around the stationary shaft. Proper lubrication is essential for bearing longevity. |

| Shell/Housing | The ductile iron or cast steel housing encloses and protects the internal components (bearings, seals). It provides the structural interface for bolting the entire assembly to the excavator's track frame. The housing must be robust to resist impacts and structural loads. |

| Lubrication Fitting | A grease zerks (fitting) is provided for periodic lubrication of the bearings and the space between the seals, which is vital for pushing out contaminants and reducing internal friction. |

3. Key Features and Technical Characteristics

Robust Material Selection: The use of high-grade alloy steel for the wheel and shaft ensures high load capacity and resistance to impact and abrasion.

Advanced Sealing Technology: The assembly likely incorporates multi-stage labyrinth seals with wear-resistant seal rings. This design is crucial for preventing the ingress of abrasive particles, which is the primary cause of seal failure and premature wear in undercarriage components.

Optimized Bearing Design: The bearings are selected and sized to handle the extreme dynamic loads and shock loads experienced during digging, lifting, and travel operations.

Efficient Lubrication: The design ensures grease permeates critical interfaces between seals and bearings, enhancing performance and service life.

Durable Housing: The strong housing, often made from cast steel or high-strength ductile iron , provides rigidity and protects the internal mechanics from direct impacts and the machine's weight.

Interchangeability & Precision Fit: The assembly is manufactured to precise dimensions to ensure a perfect fit with the SANY SY1250 excavator's track frame and proper alignment with the track chain, ensuring smooth operation.

4. Application and Compatibility

Primary Application: This carrier roller assembly is specifically designed for the SANY SY1250 hydraulic excavator.

Operating Environment: It is engineered to perform reliably in a wide range of demanding conditions typical of construction, mining, and quarrying sites, including exposure to mud, dust, rock, and water.

5. Maintenance and Care

Proper maintenance is critical for maximizing the lifespan of the carrier roller assembly:

Regular Inspection: Visually check for oil leaks from the seals, which indicate seal failure. Also, listen for unusual noises (grinding, squeaking) during operation, which may suggest bearing failure or lack of lubrication.

Cleaning: Keep the undercarriage relatively clean. Accumulated packed mud and debris can put extra strain on components and trap abrasive material against seals.

Lubrication: Adhere strictly to the manufacturer's recommended lubrication schedule using the specified type of grease. Proper greasing is the most important maintenance activity for undercarriage components.

Replacement: Carrier rollers should be replaced in sets on the same side of the machine to maintain even performance and tracking. Worn-out rollers can lead to rapid wear of the new track chain and other components.

6. Common Issues and Troubleshooting

Seal Failure: The most common issue, leading to grease leakage and contamination ingress, eventually causing bearing and roller failure.

Bearing Wear/Failure: Results in rough rotation, increased noise, and eventually seizure of the roller.

Wheel Flange Wear: The guiding flanges on the roller wheel can wear down over time, reducing their effectiveness in preventing track derailment.

External Damage: Physical damage from impacting hard objects can crack the wheel or housing.

Conclusion

The SANY-SY1250 Carrier Roller Assy is a precision-engineered, heavy-duty component vital for the stability, mobility, and longevity of the excavator's undercarriage system. Its design emphasizes durability through high-quality materials, reliability through advanced sealing, and performance by ensuring smooth track movement. Proper operation and diligent maintenance are key to achieving its maximum service life, thereby reducing downtime and operating costs for the machine.

For definitive specifications, installation instructions, and OEM part numbers, always consult the official SANY SY1250 parts manual.