Komatsu/D155 Track Shoes/560mm-17mm/for Bulldozer undercarriage Track Group

Product Specifications

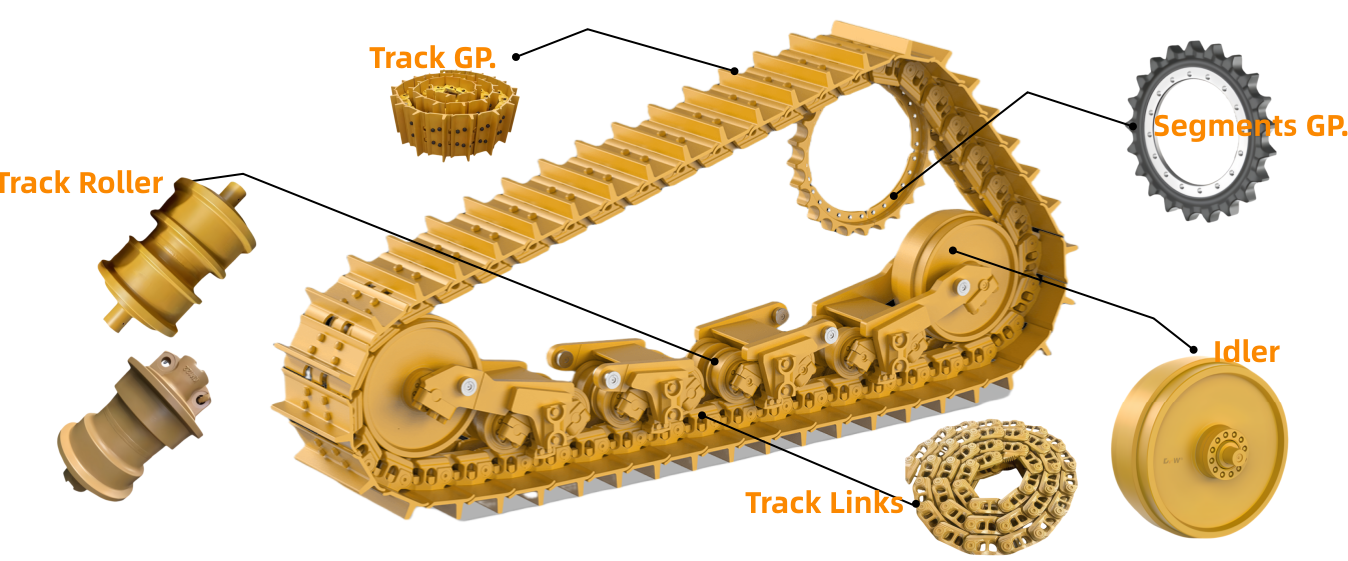

The Komatsu D155 Track Shoes Assembly/P/N 170-32-11115 170-32-E1190/(also referred to as Track Shoe Ass'y or Undercarriage Assembly) is a critical component of the bulldozer's undercarriage system. It consists of multiple individual track shoes linked together to form a continuous track chain. This assembly is responsible for:

Distributing the machine's weight evenly across the ground to minimize ground pressure and prevent sinking.

Providing traction for movement and operation on various terrains.

Protecting the undercarriage by absorbing shocks and impacts during operation.

Material: Typically made from high-strength alloy steel such as 35MnB, 23MnB, 25MnB, or 40MnB for exceptional wear resistance and durability .

Surface Hardness: Hardened to HRC 52-58 with a depth of 8-12 mm to ensure longevity and compatibility with the wear life of other undercarriage components .

Finish: Smooth surface, often available in colors like black or yellow .

Warranty: Most suppliers offer a 1-year warranty or coverage for a specified number of operating hours .

Certification: Complies with ISO9001 quality standards, ensuring reliability and performance.

3. Compatibility and Applications

Primary Model: Designed specifically for the Komatsu D155 bulldozer .

Other Compatible Models: May also fit other Komatsu bulldozer models such as D85, D150, D155, D275, and D355 depending on the design and specifications .

Applications: Widely used in construction, mining, and road engineering projects where durable and reliable undercarriage components are essential .

📦 4. Pricing and Suppliers

Pricing:

Prices range from $10 to $50 per piece for smaller quantities, with bulk orders potentially offering discounts .

Larger assemblies or customized options may cost up to $1,999 for a complete set .

Suppliers:

Shandong Maitesi Heavy Industry Machinery Co., Ltd. specializes in undercarriage parts for bulldozers and excavators, including track shoes .

Xiamen Worthpart Machinery Co., Ltd. offers a wide range of undercarriage parts, including track shoes for various models .

Other suppliers on Alibaba also provide OEM and aftermarket options .

Delivery Time: Typically 20-60 days depending on order quantity and supplier location .

🌟 5. Quality and Certification

Testing and Inspection: Reputable suppliers provide mechanical test reports and factory inspection videos to ensure quality .

Customization: Options for OEM and custom designs are available, allowing for specific requirements in terms of size, material, and application .

Packaging: Products are usually packaged securely using plywood pallets to prevent damage during shipping .

🛠️ 6. Installation and Maintenance

Installation:

Ensure proper alignment of the track shoes during assembly to prevent uneven wear and potential damage to the undercarriage.

Use appropriate tools and techniques to secure the track shoes to the track chain.

Maintenance:

Regularly inspect for wear and tear, especially in harsh operating environments.

Replace worn track shoes promptly to avoid further damage to the undercarriage system.

💎 Conclusion

The Komatsu D155 Track Shoes Assembly is a vital component for ensuring the performance and longevity of the bulldozer's undercarriage. When selecting track shoes, prioritize material quality, hardness, and compatibility with your specific machine model. Reputable suppliers like Shandong Maitesi and Xiamen Worthpart offer reliable products backed by warranties and quality certifications. For further details, refer to supplier specifications or technical manuals.