Komatsu PC2000-8(21T-27-71175)Excavator Chain Sprocket Rim/final drive sprocket

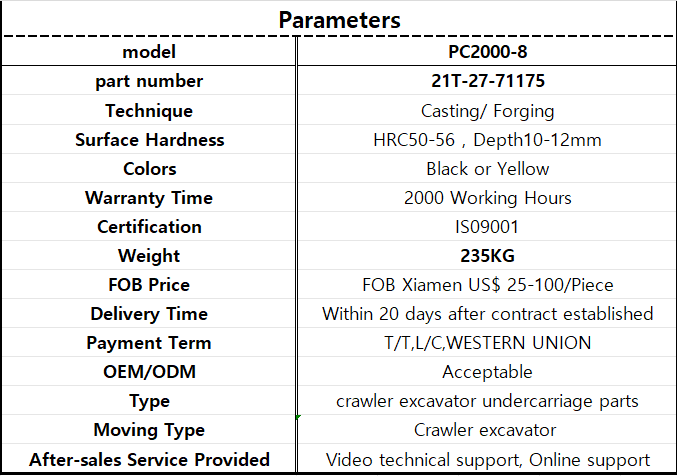

Product Specifications

Komatsu PC2000-8(21T-27-71175)Excavator Chain Sprocket Rim/final drive sprocket

Here’s a detailed breakdown of the Komatsu PC2000-8 sprocket, including part numbers, maintenance guidelines, and sourcing options for this ultra-class mining excavator:

Komatsu PC2000-8 Sprocket Specifications

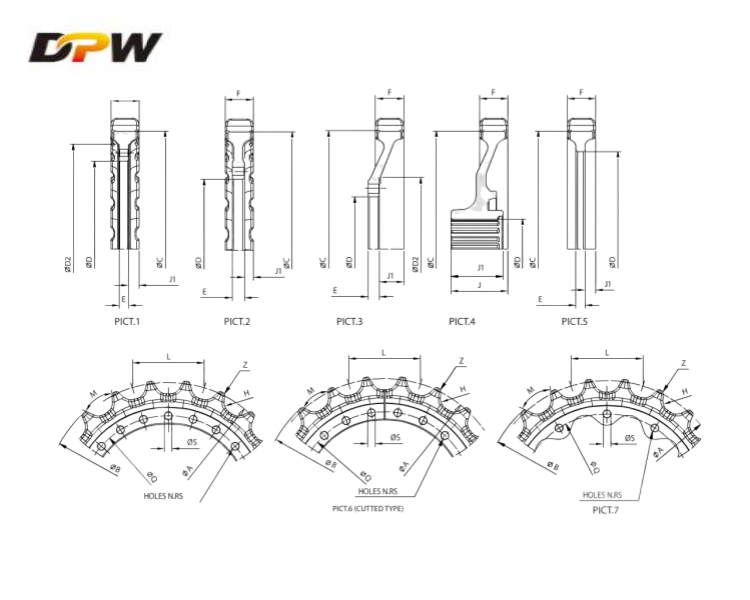

Type: Segmented sprocket (3-5 pieces) or one-piece design

Teeth Count: 23-25 teeth (varies by configuration)

Material: Forged 4140 steel with flame-hardened teeth (HRC 55-60)

Mounting: Bolted to final drive hub (M30 or M36 bolts)

Weight: ~300-400 kg per segment (full assembly ~1,200-1,500 kg)

Type: Segmented sprocket (3-5 pieces) or one-piece design

Teeth Count: 23-25 teeth (varies by configuration)

Material: Forged 4140 steel with flame-hardened teeth (HRC 55-60)

Mounting: Bolted to final drive hub (M30 or M36 bolts)

Weight: ~300-400 kg per segment (full assembly ~1,200-1,500 kg)

Hardware Kit

Bolts: 07316-00520 (M30x3.5, grade 10.9)

Nuts: 07347-60520 (hardened flange nuts)

Washers: 07367-80520 (hardened flat washers)

Bolts: 07316-00520 (M30x3.5, grade 10.9)

Nuts: 07347-60520 (hardened flange nuts)

Washers: 07367-80520 (hardened flat washers)

Aftermarket Alternatives

Premium Options:

Berco (Italy) – OEM-equivalent quality

ITR America – Mining-grade durability

ESCO – Hardened segmented designs

Cost Comparison:

OEM: 12,000 (full assembly)

Aftermarket: 9,000

Premium Options:

Berco (Italy) – OEM-equivalent quality

ITR America – Mining-grade durability

ESCO – Hardened segmented designs

Cost Comparison:

OEM: 12,000 (full assembly)

Aftermarket: 9,000

When to Replace

Wear Indicators:

Teeth worn to <70% original thickness

"Hook" formation on tooth profile

Cracked root areas or bolt hole elongation

Typical Lifespan: 10,000–15,000 hours (depends on abrasives in material)

Wear Indicators:

Teeth worn to <70% original thickness

"Hook" formation on tooth profile

Cracked root areas or bolt hole elongation

Typical Lifespan: 10,000–15,000 hours (depends on abrasives in material)

Replacement Procedure

Preparation:

Park on level ground, block tracks

Release track tension via grease cylinder

Removal:

Remove track chain using lifting equipment

Unbolt sprocket segments (impact gun @ 1,000 Nm)

Label segments for reassembly orientation

Installation:

Clean hub surface thoroughly

Apply Komatsu anti-seize (P/N 20Y-63-12200)

Torque bolts in staggered pattern to 1,100 Nm (810 lb-ft)

Preparation:

Park on level ground, block tracks

Release track tension via grease cylinder

Removal:

Remove track chain using lifting equipment

Unbolt sprocket segments (impact gun @ 1,000 Nm)

Label segments for reassembly orientation

Installation:

Clean hub surface thoroughly

Apply Komatsu anti-seize (P/N 20Y-63-12200)

Torque bolts in staggered pattern to 1,100 Nm (810 lb-ft)

Maintenance Tips

Monthly Checks:

Measure tooth thickness with calipers

Inspect for cracks (dye-penetrant test if needed)

Lubrication:

Final drive oil: ISO 100 (SAE 30)

Bolt threads: Molykote P37 paste

Monthly Checks:

Measure tooth thickness with calipers

Inspect for cracks (dye-penetrant test if needed)

Lubrication:

Final drive oil: ISO 100 (SAE 30)

Bolt threads: Molykote P37 paste

Where to Buy

www.hangongmachinery.com

www.cqctrack.com

Troubleshooting Guide

Issue Likely Cause Solution Premature wear Misaligned track Check idler/sprocket alignment Bolt failures Under-torquing Re-torque to spec with calibrated wrench Vibration Worn final drive splines Inspect hub/spline engagement

| Issue | Likely Cause | Solution |

|---|---|---|

| Premature wear | Misaligned track | Check idler/sprocket alignment |

| Bolt failures | Under-torquing | Re-torque to spec with calibrated wrench |

| Vibration | Worn final drive splines | Inspect hub/spline engagement |

Need More Help?

For precise information:

Provide your machine serial number (located on right-front frame)

Specify if you need:

Exploded diagrams

Local supplier contacts

Torque sequence diagrams

Let me know how I can assist further!