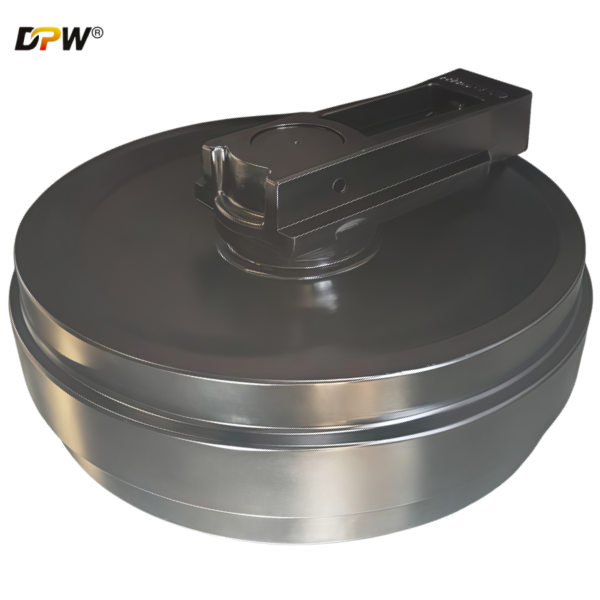

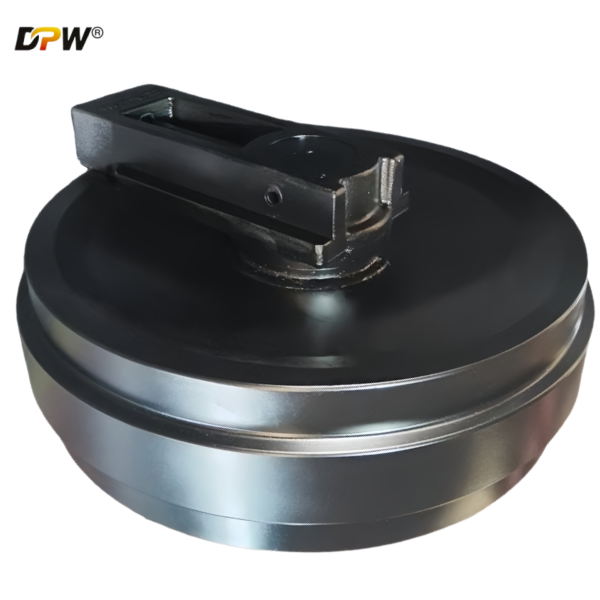

Komatsu KM2224 PC750/PC800/PC850 Track Idler Wheel Assembly

Product Specifications

Komatsu KM2224 Track Idler Wheel Assembly for PC750/PC800 Excavators

Product Overview & Core Value Proposition

The Komatsu KM2224 Track Idler Wheel Assembly is a precision-engineered, critical undercarriage component designed as a direct OEM replacement for Komatsu PC750 and PC800 series hydraulic excavators. Functioning as the front idler, this assembly is pivotal for ensuring precise track guidance, maintaining optimal track tension, and facilitating dynamic load distribution under the most demanding operating conditions in mining, construction, and heavy earthmoving. Manufactured from high-strength alloy steel and subjected to advanced heat treatment processes, it delivers unparalleled wear resistance, impact strength, and operational longevity, reducing total cost of ownership by minimizing downtime and protecting adjacent undercarriage parts.

Technical Specifications & Key Attributes

Parameter Specification OEM Part Number KM2224 Compatible Models Komatsu PC750, PC750LC-6, PC800, PC800LC-6 Application Excavator Undercarriage System Core Material High-Carbon Chromium Steel (SUJ2 Equivalent) Hardness Rating HRC 58-62 Heat Treatment Quenching & Tempering Sealing System Multi-Layered Nitrile Rubber (NBR) Lip Seals Lubrication Lithium-Based High-Temperature Grease Quality Standards ISO 9001, CE Compliance

| Parameter | Specification |

|---|---|

| OEM Part Number | KM2224 |

| Compatible Models | Komatsu PC750, PC750LC-6, PC800, PC800LC-6 |

| Application | Excavator Undercarriage System |

| Core Material | High-Carbon Chromium Steel (SUJ2 Equivalent) |

| Hardness Rating | HRC 58-62 |

| Heat Treatment | Quenching & Tempering |

| Sealing System | Multi-Layered Nitrile Rubber (NBR) Lip Seals |

| Lubrication | Lithium-Based High-Temperature Grease |

| Quality Standards | ISO 9001, CE Compliance |

Detailed Technical Features & Engineering Benefits

1. Heavy-Duty Load Bearing & Structural Integrity

Forged High-Carbon Chromium Steel construction provides a superior balance of core toughness and surface hardness (HRC 58-62), effectively withstanding high-impact shocks and cyclic stresses.

Reinforced axle and hub design engineered to manage extreme radial and axial loads encountered in rocky, mining, and challenging terrain applications.

2. Precision Track Guidance & System Synergy

Optimized flange geometry and profile are CNC-machined to prevent track derailment and misalignment, ensuring stable linear travel and responsive steering control.

Designed for system synergy, working in concert with sprockets, rollers, and track chains to minimize internal friction, reduce power loss, and promote even wear across the entire undercarriage system.

3. Enhanced Durability & Corrosion Protection

Quenching and tempering processes significantly enhance the metallurgical structure, increasing surface hardness for abrasion resistance while maintaining a tough core to prevent cracking.

Corrosion-resistant coating is applied to protect against abrasive wear from mud, slurry, and chemically aggressive site conditions, extending service life.

4. Advanced Sealing & Lubrication System

Multi-layered Nitrile (NBR) lip seals create a robust barrier against contaminant ingress (dust, water, silt) and effectively retain vital lubricants within the assembly.

High-performance lithium-complex grease ensures consistent lubrication and smooth rotation at sustained temperatures up to 120°C, significantly extending maintenance intervals and bearing life.

Manufacturing Excellence & Quality Assurance

Precision CNC Machining: Guarantees dimensional accuracy with tolerances held within ±0.05 mm for seamless, drop-in integration with OEM undercarriage systems.

Rigorous Quality Assurance: Every batch undergoes validation via spectrometer analysis for material composition and hardness testing to verify mechanical properties meet or exceed OEM standards.

Secure Export Packaging: Components are housed in export-ready wooden crates with waterproof internal packaging to guarantee transit safety and arrive in perfect, ready-to-install condition.

Precision CNC Machining: Guarantees dimensional accuracy with tolerances held within ±0.05 mm for seamless, drop-in integration with OEM undercarriage systems.

Rigorous Quality Assurance: Every batch undergoes validation via spectrometer analysis for material composition and hardness testing to verify mechanical properties meet or exceed OEM standards.

Secure Export Packaging: Components are housed in export-ready wooden crates with waterproof internal packaging to guarantee transit safety and arrive in perfect, ready-to-install condition.

Compatibility & Professional Replacement Guidance

This assembly is a direct OEM-quality replacement for the genuine Komatsu KM2224 part.

Professional Recommendation: For balanced performance and to prevent uneven track wear, it is highly advised to replace idlers in paired sets (left and right) simultaneously.

System Compatibility: Fully compatible with the PC750/PC800 "four wheels and one belt" undercarriage system, which includes track rollers, carrier rollers, and the final drive sprocket.

This assembly is a direct OEM-quality replacement for the genuine Komatsu KM2224 part.

Professional Recommendation: For balanced performance and to prevent uneven track wear, it is highly advised to replace idlers in paired sets (left and right) simultaneously.

System Compatibility: Fully compatible with the PC750/PC800 "four wheels and one belt" undercarriage system, which includes track rollers, carrier rollers, and the final drive sprocket.

Frequently Asked Questions (FAQ)

Q: Is this idler assembly a direct fit for my Komatsu PC750LC-6 excavator?

A: Yes, absolutely. The KM2224 is a direct OEM replacement specifically engineered for the PC750LC-6 and PC800LC-6 models. Always confirm your machine's serial number for final validation.

Q: Do you offer custom branding or modifications for large volume orders?

A: Yes, we support OEM/ODM customization for bulk orders, including custom branding, dimensional adjustments, and specific material grade requirements. Minimum Order Quantity (MOQ) and lead times will be confirmed based on your project scope.

Q: What are the operational efficiency benefits of using this idler wheel?

A: By ensuring precise track alignment and reducing rolling resistance, this idler assembly can contribute to a reduction in track resistance by 15–20%, leading to lower fuel consumption and decreased premature wear on costly adjacent components like track chains and sprockets.

Q: What are your standard warranty and delivery terms?

A: We offer a standard 3-month warranty on this assembly. For orders of 5 units or more, delivery is typically within 5–8 working days. We accept payment via Telegraphic Transfer (T/T) or Letter of Credit (L/C).