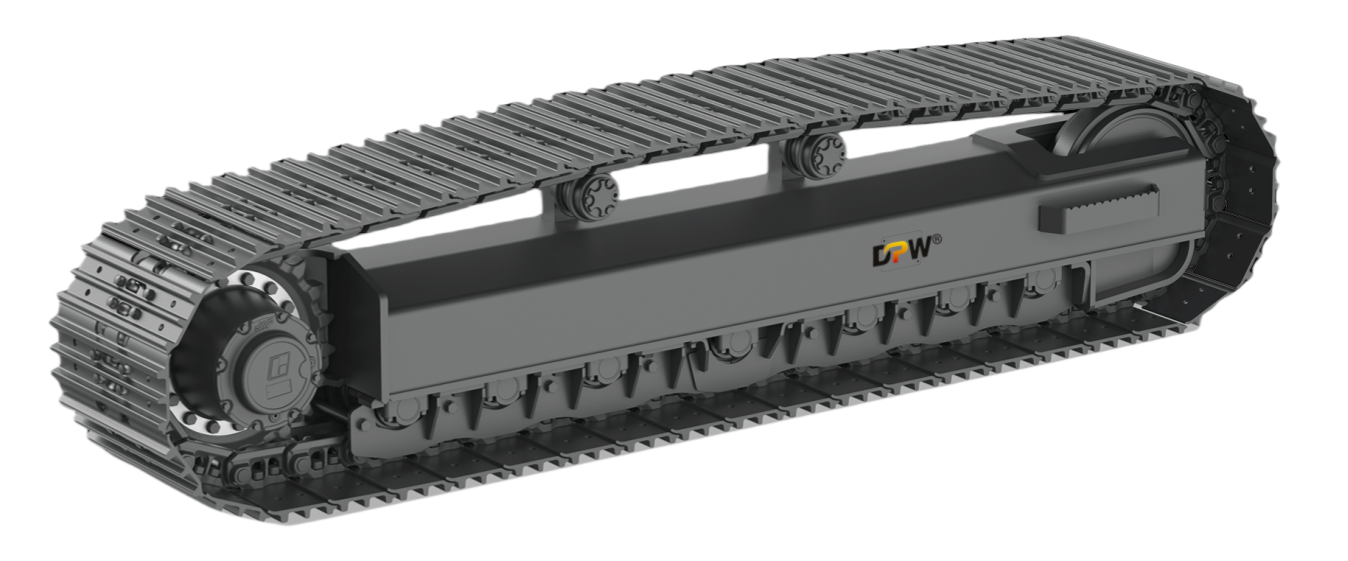

Komatsu-BR200-1/PC200/BP500-3 Track Roller Assy/OEM quality undercarriage components manufacture and supplier

Product Specifications

Comprehensive Technical Description: Komatsu PC200/BR200-1/BP500-3 Track Roller Assembly

1. Definition and Primary Function

The Track Roller Assembly (also known as a lower roller or bottom roller) is a critical undercarriage component on the Komatsu PC200-10 and PC200-11 hydraulic excavators. Its primary functions are to:

Support Machine Weight: Work in conjunction with other undercarriage components to support and distribute the significant weight of the excavator.

Guide Track Chain: Ensure the track chain maintains proper alignment and travels smoothly along the track frame during operation, preventing derailment.

Reduce Friction: Facilitate smooth movement of the track chain, reducing friction and wear across the undercarriage system.

Absorb Shock: Help absorb shocks and impacts encountered during operation on rough or uneven terrain.

2. Key Components and Construction

A standard Track Roller Assembly for these models typically consists of the following integral parts:

3. Technical Specifications & Compatibility

Compatible Models: Specifically designed for the Komatsu PC200-10 and PC200-11 excavators. May also be compatible with other PC200 series models (e.g., PC200-8, PC200-9), but verification against specific part numbers is essential.

Undercarriage Configuration: Each side of the machine typically features 7 track rollers (bottom rollers) and 2 carrier rollers (top rollers).

Track Gauge: The standard track (track shoe width) for these models is 600 mm.

Load Capacity: Engineered to handle the operating weights of approximately 19,600 kg (PC200-10) and 20,500 kg (PC200-11), along with dynamic and shock loads during digging and travel.

4. Design and Performance Features

Robust Material Science: Utilization of high-grade alloy steels and advanced heat treatment processes ensures optimal hardness and toughness, balancing surface wear resistance with core strength to prevent cracking.

Advanced Sealing Technology: Multi-labyrinth seals are critical for preventing premature failure by creating multiple barriers against the ingress of abrasive particles, which is the primary cause of seal and bearing degradation in undercarriage components.

Precision Engineering: Components are manufactured to tight tolerances to ensure precise fitment, correct alignment with the track chain, and smooth operation, minimizing vibration and uneven wear.

Durable Construction: The forged or cast housing and hardened components are built to resist deformation, flaring, and mechanical damage from impacts with rocks and other hard objects.

Optimized Lubrication: The internal design and grease fitting allow for effective lubrication, reducing internal friction and wear on bearings and contact surfaces.

5. Application and Operating Environment

This assembly is designed to perform reliably in a wide range of demanding operating conditions, including:

Construction sites

Mining and quarrying operations

Road building

Landscaping

Exposure to abrasive environments like sand, gravel, mud, and rock is common, underscoring the importance of its robust design and sealing.

6. Maintenance, Common Issues, and Troubleshooting

Recommended Maintenance:

Regular Cleaning: Keep the undercarriage free of packed mud and debris to reduce strain on components and prevent abrasive wear near seals.

Periodic Lubrication: Adhere to Komatsu's recommended lubrication intervals (often every 50 operating hours) using the specified type of grease. Proper greasing is vital for expelling contaminants and prolonging life.

Routine Inspection: Frequently check for signs of grease leakage (indicating seal failure), uneven wear patterns on the roller flanges, and unusual noises (grinding or squeaking, suggesting bearing issues).

Common Failure Modes:

Seal Failure: The most common issue, leading to grease loss and contamination ingress, rapidly causing bearing and roller wear.

Bearing Wear/Failure: Results in increased rotational resistance, noise, and eventual roller seizure.

Flange Wear: The guiding flanges can wear down over time, reducing their effectiveness in preventing track derailment.

Wheel or Housing Damage: Cracking or significant deformation due to severe impacts.

Replacement Consideration:

Track rollers should ideally be replaced in sets on the same side of the machine to maintain uniform performance and prevent accelerated wear on new and old components alike.

Always refer to the official Komatsu service manual for detailed repair standards, clearance specifications, and torque values.

7. OEM, Aftermarket, and Procurement

OEM Part Numbers: While specific part numbers for the PC200-10/11 assembly were not found in the search results, part numbers for similar models (e.g.,

20Y-30-16152for older PC200 models) exist. Consulting Komatsu's official parts catalog is essential for the correct part number.Aftermarket Availability: High-quality aftermarket replacements are available from various manufacturers (e.g., ). These often adhere to international quality standards like ISO9001 and may offer warranties (e.g., 1 year).

Selection Advice: When sourcing replacements, prioritize suppliers that provide material certifications, hardness testing reports, and detailed specifications to ensure compatibility and durability comparable to OEM components.

8. Importance in the Undercarriage System

The Track Roller Assembly works in concert with other undercarriage components—idlers (guidance rollers), sprockets (final drives), carrier rollers (upper rollers), and track chains—to form a complete system. Its health directly impacts:

Machine Stability: Crucial for safe operation, especially on slopes.

Tracking Ability: Prevents derailment and ensures straight travel.

Overall Undercarriage Life: A worn roller can accelerate wear on the track chain links and bushings, leading to increased operating costs.

Fuel Efficiency: Properly functioning undercarriage components minimize rolling resistance.

Conclusion

The Komatsu PC200-10/11 Track Roller Assembly is a precision-engineered, heavy-duty component essential for the stability, mobility, and productivity of the excavator. Its design emphasizes maximum durability and service life through the use of high-quality materials, advanced sealing technology, and robust construction. Proactive maintenance and timely replacement using quality parts are paramount to minimizing downtime and reducing the total cost of ownership for the machine.

For definitive specifications, official part numbers, and detailed maintenance procedures, always consult the Komatsu PC200-10/11 Service Manual or authorized Komatsu dealers.