Komatsu 21N3000130 PC1100/PC1250 Track Roller Assembly/China heavy duty Mining and Construction machinery undercarriages manufacture-DPW PARTS

Product Specifications

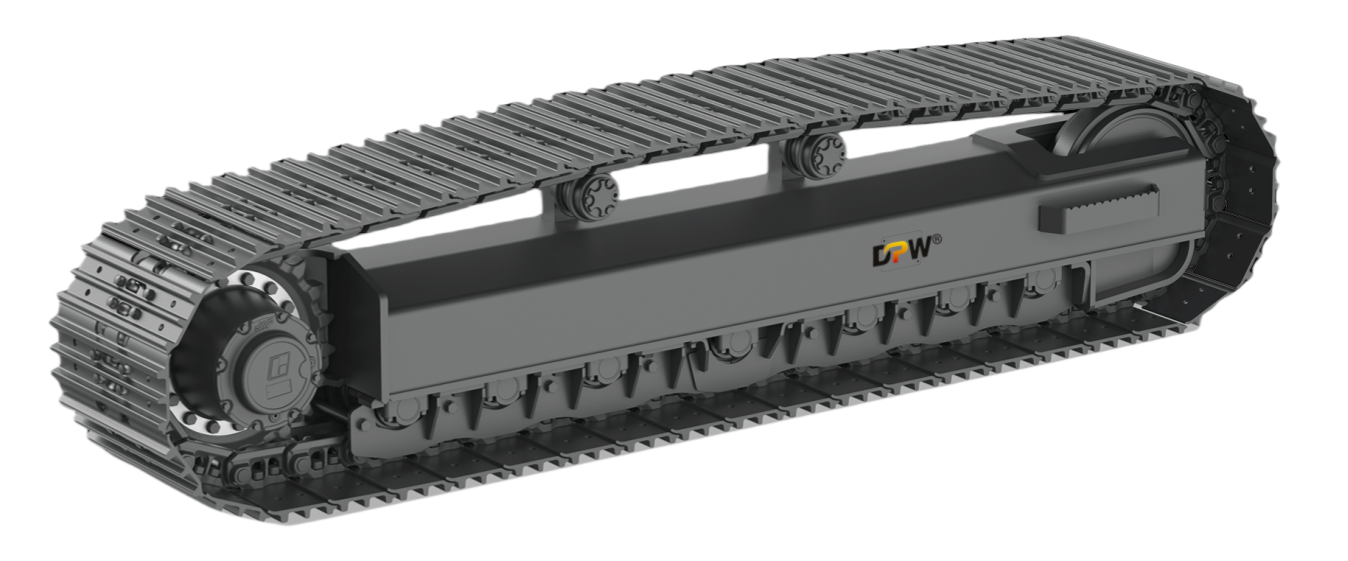

The Carrier Roller Group (often referred to as the Track Roller Assembly or Upper Roller Assembly) is a critical component within the undercarriage system of large mining excavators like the Komatsu PC1100 and PC1250 series. Its primary functions are to support the upper section of the track chain, maintain track alignment (preventing lateral derailment), and reduce friction during track movement.

✨ Note: The exact part number for your specific machine (e.g., PC1250-7, PC1250-8, PC1250-11R) and configuration is crucial, as designs can vary between models and generations. Always confirm compatibility using your machine's serial number.

1. Key Components of the Carrier Roller Group

A complete Carrier Roller Group is a pre-assembled, sealed unit typically consisting of:

Carrier Roller (Upper Roller): The hardened, durable outer shell that makes direct contact with the track chain links. It features double flanges (raised edges on both sides) crucial for guiding the track and preventing derailment during operation and turns.

Shaft (Axle): The stationary, high-strength steel pin that serves as the central axis for the roller's rotation. It is mounted to the track frame.

Bearings: High-capacity, tapered roller bearings or journal bearings that allow the roller to rotate smoothly with minimal friction around the fixed shaft.

Seals (Labyrinth Seals): Extremely Critical. Multi-layered, heavy-duty seals designed to create a barrier against the ingress of abrasive contaminants (dust, mud, water, rock particles) and to retain the internal lubricant. The effectiveness of these seals is a primary determinant of the roller's service life.

Internal Lubricant: High-quality, high-temperature grease specifically formulated for undercarriage components to provide continuous lubrication, reduce wear, and dissipate heat.

Mounting Hardware: Includes bolts, nuts, and sometimes spacers used to secure the assembly to the excavator's track frame.

2. Material & Manufacturing Technology

Material: Manufactured from high-carbon, high-chromium alloy steel (e.g., 40Mn2, 50Mn). The roller's outer rim undergoes specialized heat treatment processes like induction quenching or case carburizing. This creates an extremely hard, wear-resistant outer surface (typically achieving a hardness of 52-58 HRC) while maintaining a tougher, more shock-absorbent core to withstand impacts.

Precision Machining: Components are machined to precise tolerances to ensure perfect fitment, balance, and smooth rotation, which minimizes vibration and uneven wear.

Sealing Technology: Employs advanced multi-path labyrinth sealing systems, often utilizing wear-resistant seal rings and high-performance nitrile rubber (NBR), to achieve exceptional protection against harsh environments.

3. Importance & Functions in the Undercarriage System

The Carrier Roller Group is vital for:

Track Guidance & Alignment: The flanges keep the track chain centered on the track frame, especially during side loads and turns.

Support: Bears the weight of the track chain's upper section and helps distribute the machine's operational loads.

Reducing Friction & Wear: Facilitates smooth movement of the track chain, minimizing energy loss and wear on both the roller itself and the track chain links.

Contaminant Exclusion: Effective seals protect the internal bearings from premature failure, which is the most common cause of roller seizure.

4. Compatibility & Application

Carrier Roller Groups are model-specific. They are designed to be compatible with the track chain pitch and overall undercarriage design of:

Komatsu PC1100 series mining excavators (e.g., PC1100SP-6, which has an operating weight of ~104,000 kg).

Komatsu PC1250 series mining excavators (e.g., PC1250-7 with an operating weight of ~106,700 kg, PC1250-8 with ~109,900 kg, and the newer PC1250-11R with ~117,800 kg).

Using a roller group not specifically designed for your exact machine model can lead to rapid wear, improper track movement, and potential damage to other undercarriage components.

5. Key Performance Characteristics

Exceptional Wear Resistance: The hardened material and robust construction are engineered to extend service life in abrasive conditions, reducing downtime and cost-per-hour of operation.

High Load-Bearing Capacity: Designed to withstand the immense static and dynamic loads generated by these multi-ton excavators.

Impact Resistance: The tough core material helps absorb shocks from obstacles like large rocks.

Superior Sealing: Effective sealing is paramount for longevity in mining and quarry applications where exposure to contaminants is extreme.

Optimized Lubrication: High-quality internal grease ensures smooth operation across a wide temperature range.

6. Maintenance & Replacement Considerations

Genuine vs. OEM Quality: While genuine Komatsu parts offer guaranteed compatibility and performance, high-quality OEM (Original Equipment Manufacturer) or aftermarket equivalents (like those from reputable suppliers such as Beneparts) can provide a reliable alternative, often at a different price point. These should meet or exceed original specifications for materials, heat treatment, and sealing.

Proper Installation: Correct torque procedures for mounting bolts are critical to prevent damage.

Undercarriage Inspection: Regular inspection of the entire undercarriage (rollers, idlers, sprockets, track chain) for wear patterns is essential for proactive maintenance. Carrier rollers should be checked for smooth rotation, visible flange wear, and oil leaks (indicating seal failure).

7. Potential Part Numbers (Example)

An example part number for a PC1250-8 Track Roller Assy is 21N3000130.

However, part numbers can vary based on the specific dash number (e.g., -7, -8, -11R) and the roller's position on the track frame. Always consult the official Komatsu parts manual for your specific serial number to obtain the correct part number.

Summary Table

| Feature/Aspect | Description & Specifications |

|---|---|

| Primary Function | Supports the upper track chain, maintains alignment, guides track, reduces friction. |

| Key Components | Roller with double flanges, shaft, bearings, labyrinth seals, internal grease. |

| Compatible Models | Komatsu PC1100 (e.g., PC1100SP-6), PC1250 (e.g., -7, -8, -11R) series excavators. |

| Material | High-carbon, chromium alloy steel (e.g., 40Mn2, 50Mn). |

| Heat Treatment | Induction quenching or case carburizing. |

| Surface Hardness | 52 - 58 HRC (typical). |

| Critical Feature | Multi-path labyrinth sealing system to exclude contaminants. |

| Importance | Essential for undercarriage longevity, machine stability, and operating efficiency. |

| Replacement Tip | Always verify part number compatibility using the machine's serial number. |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||