Kobelco YT64D00004F1 SK330-10/SK380-10 Track Bottom/lower roller/Heavy-Duty Undercarriage Replacement Part

Product Specifications

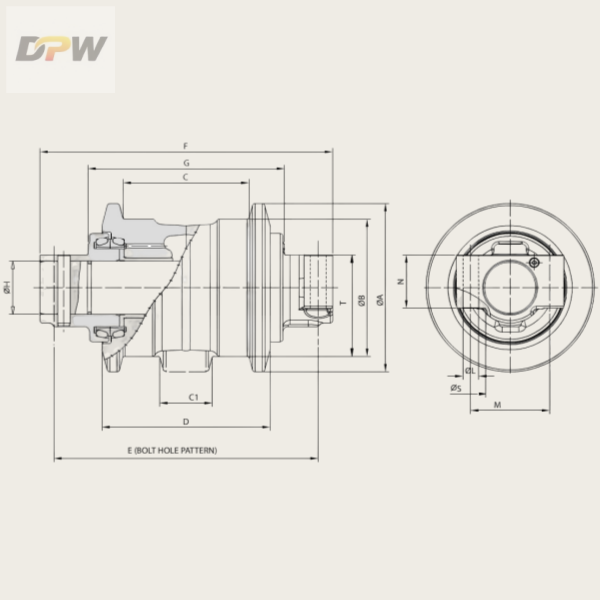

Technical Description: Kobelco SK380-10 Track Bottom Roller Assembly

1. General Overview & Functional Definition

The Kobelco SK330-10/SK380-10 Track Bottom Roller Assembly is a quintessential load-bearing component within the undercarriage system of the Kobelco SK380-10 hydraulic excavator. Positioned along the bottom of the track roller frame, these assemblies form the primary interface between the machine's immense weight and the track chain. Their core functions are:

Primary Static and Dynamic Load Support: They bear the brunt of the machine's operational weight, distributing the load from the mainframe through the track chain and onto the ground via the track shoes. They must withstand both constant static loads and dynamic shock loads from uneven terrain.

Precise Track Chain Guidance: The rollers guide the bottom (ground-running) section of the track chain, maintaining its precise linear path and alignment between the front idler and the drive sprocket, ensuring stable and predictable machine travel.

Shock and Vibration Absorption: As the first point of contact for ground-induced forces, they absorb and dampen vertical shocks and vibrations from traversing over rocks, debris, and uneven surfaces. This protects the more sensitive components of the undercarriage and the mainframe itself.

Reduction of Frictional Resistance: By providing a continuous, sealed, and lubricated rolling surface, they minimize the friction between the track chain's inner bushing and the roller frame, enabling efficient machine travel and reducing power loss.

2. Detailed Component Breakdown & Technical Specifications

This assembly is a self-contained, pre-lubricated unit engineered for maximum service life and reliability in demanding applications.

2.1. Roller Wheel (or Tread)

Material & Manufacturing: Forged from high-carbon, abrasion-resistant steel such as SCMnH3 or equivalent Mn-Cr alloy steel. The forging process ensures a dense, non-porous microstructure with superior impact strength and fatigue resistance.

Design Features:

Dual-Flange Design: Standard for most lower rollers, featuring two integral, robust flanges. These are precision-machined to provide positive lateral guidance for the track chain links, preventing derailment during turning and side-slope operation.

Deep Hardened Tread: The outer running surface is subjected to high-frequency induction hardening. This process creates a deep, hardened case (typically 6-8 mm) with a surface hardness of 58-63 HRC, engineered to resist the severe grinding abrasion from the track chain bushings.

Optimized Profile: The tread and flange are designed with specific radii and contours to ensure smooth engagement with the track bushing and to minimize stress concentration at the flange root.

2.2. Stationary Roller Shaft (Axle Pin)

Function: This is the non-rotating mounting pin that secures the entire roller assembly to the track roller frame. It acts as a structural beam, transferring all operational loads from the roller into the frame.

Material & Specification: Manufactured from high-strength alloy steel like SCM435 (equivalent to 34CrMo4), followed by a quenching and tempering heat treatment. This provides an excellent combination of high surface hardness for wear resistance at the mounting points and a tough, ductile core to resist bending and shock loads.

2.3. Bearing System

Type: The SK380-10 typically utilizes a Long-Life, High-Capacity Needle Roller Bearing or a Double-Row Tapered Roller Bearing configuration. These are chosen for their exceptionally high radial load capacity relative to their size.

Function:

Ultra-High Radial Load Support: Specifically engineered to support the extreme weight of a 38-ton-class excavator.

Compact Design: Allows for a larger diameter shaft and more robust roller construction within a confined space.

Pre-lubricated and Sealed: The bearing cavity is packed with high-performance, high-temperature lithium soap EP grease during assembly.

2.4. Advanced Multi-Labyrinth Sealing System

Configuration: Kobelco often employs a sophisticated Multi-Labyrinth Seal with Floating Seal Rings or reinforced Radial Lip Seals. This system is critical for the harsh environments in which excavators operate.

Function:

Primary Labyrinth Seal: Creates a tortuous path that physically blocks and expels large contaminants like sand and mud.

Floating Face Seal (if equipped): Consists of two precision-ground, spring-loaded seal rings (often carbide-coated) that create a highly reliable, positive seal against fine abrasives and water, even under shaft deflection.

Grease Purge Chamber: The design often includes a chamber that can be purged with new grease via a zerk fitting, helping to force out any contaminants that have penetrated the outer defenses.

2.5. Hub & Outer Housing

The hub is the central rotating component that is pressed into the roller wheel. It contains the bore for the needle roller bearings and the sealing surfaces.

The outer housing is the structural shell of the roller that directly contacts the track chain bushing. It is designed for maximum wear resistance and structural integrity.

3. Integration within the SK380-10 Undercarriage System

The Bottom Roller Assembly is a system-critical component:

It is bolted directly onto the Track Roller Frame via the stationary shaft.

It works in concert with the Front Idler, Top Carrier Rollers, and Drive Sprocket to form a continuous track loop.

Multiple rollers (typically 7 or 9) are installed per side to ensure even weight distribution and stable ground contact pressure along the entire track length.

4. Critical Performance & Maintenance Parameters

Wear Limit Adherence: Kobelco provides strict maximum wear limits for the roller's outer diameter and flange height. Exceeding these limits allows excessive track sag, leading to accelerated wear on the chain, sprocket, and other rollers, and increases the risk of de-tracking.

Flange Integrity Monitoring: The flanges must be inspected for wear and cracking. Worn flanges can no longer guide the track effectively, leading to lateral track whip and potential failure.

Seal Integrity and Re-lubrication: Regular inspection for seal damage (evidenced by grease leakage) is paramount. While many are "sealed for life," some designs allow for preventive re-lubrication to extend service life. A seized roller must be replaced immediately to prevent catastrophic damage to the track chain.

Frame Alignment and Bolt Torque: Proper alignment of the track frame and correct torque on the roller shaft bolts are essential to prevent uneven loading and premature failure.

5. Failure Mode and Effects Analysis (FMEA)

Accelerated Tread Wear: Caused by operation on highly abrasive substrates or chronic improper track tension.

Flange Fracture or Severe Wear: Typically results from aggressive, high-speed turning on hard surfaces or persistent side-loading on slopes.

Bearing Seizure: The ultimate consequence of seal failure, leading to contamination, loss of lubrication, and the roller locking up. A seized roller will rapidly grind down the track bushing.

Shaft Breakage: A rare but severe failure usually caused by an extreme impact or a pre-existing crack propagating from a stress concentrator.

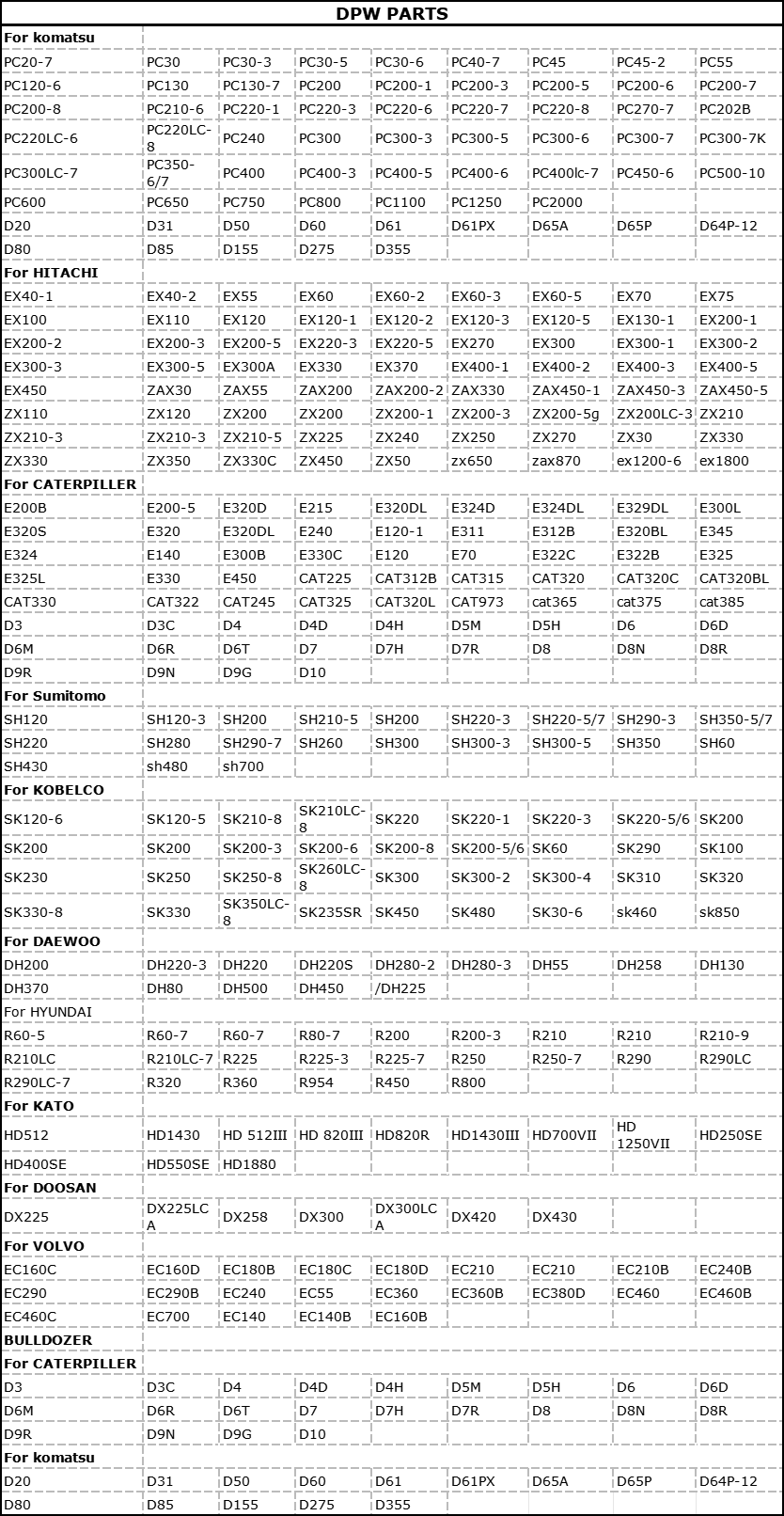

DPW machinery parts produces 2,000+ undercarriage parts for excavators/dozers/loaders (all major brands except Kobelco), plus custom solutions for specialized applications.