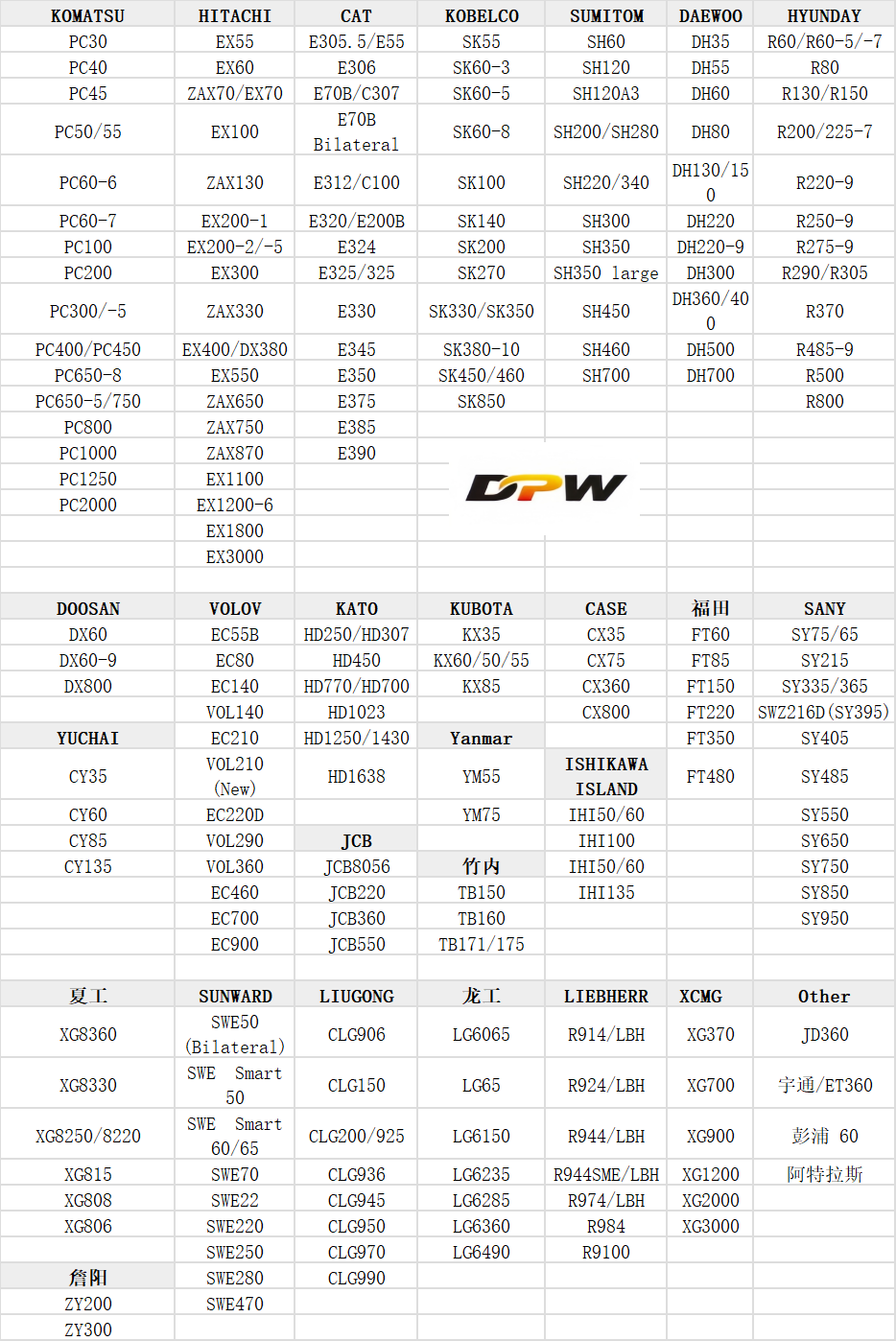

KOBELCO excavator(LB52D00002F1;LB52D00002F3;P1627401Y00)SK270-track front idler GP/forging idler factory direct/spare part idler manufacture/china idler rollers factory/undercarriage part factory china

Product Specifications

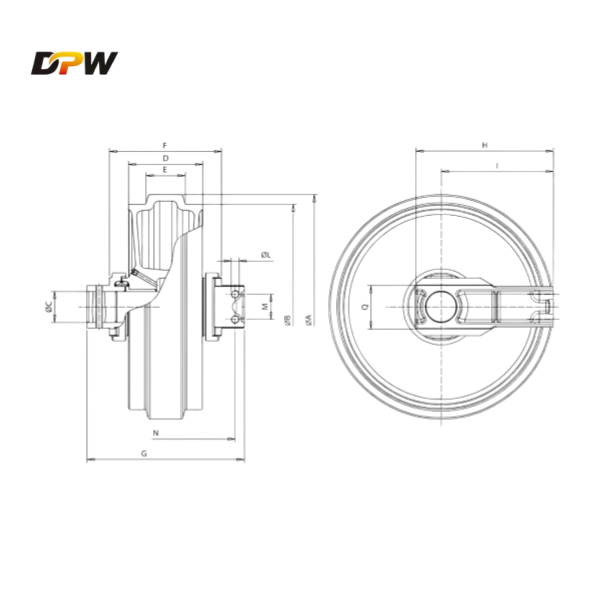

SK270 Forged Front Idlers – Heavy-Duty Track Guide Rollers for 24-27Ton Excavators,KOBELCO excavator SK250/270 Model undercarriage part,forging idler ass'y.

SK270 forged front idlers are ultra-durable undercarriage components designed for 27-30 ton excavators, built to withstand extreme conditions in mining, quarrying, and heavy construction. Manufactured through precision hot forging, these idlers offer superior strength and longevity compared to standard cast rollers.

Key Features & Benefits

✔ Forged Alloy Steel Construction – Higher density, fewer defects, and better fatigue resistance than cast idlers

✔ Deep Induction Hardening (HRC 55-60) – 4-6mm hardened depth for maximum wear resistance

✔ Double-Labyrinth Sealed Bearings – Prevents contamination in wet, muddy, or dusty environments

✔ Optimized Flange Design – Reinforced for better track guidance and reduced derailment risk

✔ OEM Interchangeable – Direct replacement for Komatsu PC270, Hitachi ZX270, Caterpillar 329, and Volvo EC290 models

Technical Specifications

| Parameter | Specification |

|---|---|

| Load Capacity | 12,000 kg (dynamic) |

| Bearing Type | Heavy-duty tapered roller bearings |

| Flange Thickness | 22mm (reinforced) |

| Weight | 145 kg (standard) |

| Surface Treatment | Shot-peened for stress relief |

Compatible Machines

FIAT-KOBELCO/NEW HOLLANDE305C NBLA09886-UP E305C NRC NLCA10973-UP

KOBELCOSK250HD MARK VI SK250HD-LC MARK VI SK250HD-NLC MARK VI SK270 SK270LC

| E305C NBLA09886-UP | E305C NRC NLCA10973-UP |

| SK250HD MARK VI | SK250HD-LC MARK VI | SK250HD-NLC MARK VI | SK270 |

| SK270LC | |

Why Choose Forged Front Idlers?

✅ 40% Longer Service Life – More resistant to wear, cracks, and deformation

✅ Higher Impact Resistance – Withstands shock loads from rock and demolition work

✅ Reduced Maintenance Costs – Fewer replacements and less downtime

When to Replace SK270 Forged Front Idlers?

⚠ Flange wear exceeds 30% of original thickness

⚠ Visible cracks, spalling, or deep grooves on the rolling surface

⚠ Bearing play >2mm or grinding noise during operation

⚠ Grease leakage due to seal failure

Maintenance Recommendations

Clean after each shift – Remove mud, rocks, and debris to prevent accelerated wear

Inspect every 500 hours – Check for abnormal wear patterns and bearing play

Replace in sets (minimum 2 idlers) – Ensures balanced track tension and alignment

Available Upgrades

Tungsten Carbide Overlay (TCO) – For extreme abrasion resistance in mining

Telemetry-Enabled Idlers – RFID sensors for real-time wear monitoring

Arctic/Cold Weather Version – Special seals and lubricants for sub-zero operations