KOBELCO LC52D00026F1 / LC52D00002F1 SK330/SK350 Forged Track Idler Assembly/Heavy duty excavator spare parts /Professional forged Track guide wheel manufacturing factory-HAN GONG/DPW PARTS

Product Specifications

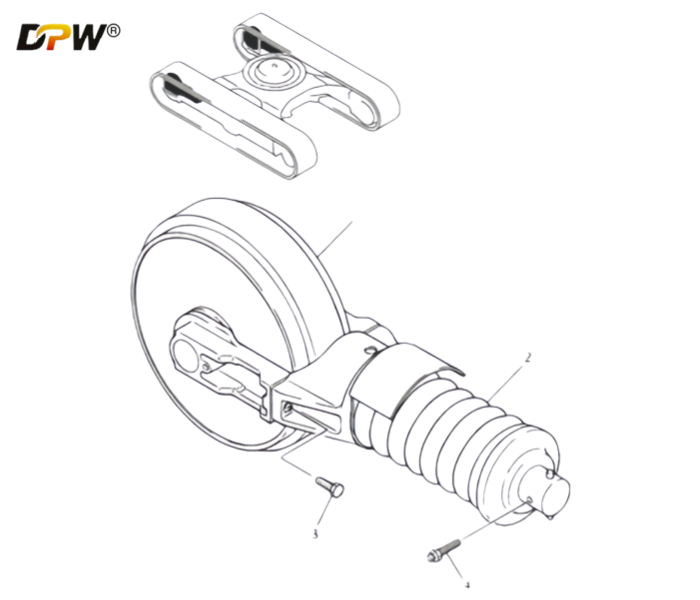

KOBELCO SK330/SK350 Forged Track Idler Assembly (LC52D00026F1 / LC52D00002F1): Technical Specifications & Manufacturing Excellence by HAN GONG/DPW PARTS

Executive Summary

This document provides a comprehensive technical exposition of the heavy-duty forged track idler assemblies (Part Numbers: LC52D00026F1, LC52D00002F1) engineered for KOBELCO SK330 and SK350 series excavators. Manufactured by the professional forged track guide wheel factory HAN GONG/DPW PARTS, these components exemplify the superior durability, performance, and reliability achieved through precision hot forging and integrated quality management. This content serves as an authoritative resource for equipment managers, maintenance engineers, and procurement specialists in the heavy machinery sector.

1. Product Identification & Application

1.1 Core Function of the Track Idler

The track idler, or front idler, is a foundational element of the crawler undercarriage system, performing critical roles:

Track Guidance and Alignment: Ensures the track chain runs true, preventing lateral drift and potential derailment.

Dynamic Tension Regulation: Acts as the pivotal point for the track tensioning system, maintaining optimal tension across varying terrain and operating conditions.

Structural Load Management: Supports a portion of the machine's operational weight and absorbs forward/backward loads during travel and digging.

Primary Shock Attenuation: First point of contact for ground-induced impacts, protecting more sensitive drivetrain and structural components.

1.2 Target Machinery & Model Compatibility

Primary Application: KOBELCO SK330 Series Hydraulic Excavators (including various dash numbers, e.g., SK330-8, SK330LC-8).

Primary Application: KOBELCO SK350 Series Hydraulic Excavators (including various dash numbers, e.g., SK350-8, SK350LC-8).

Note: Specific model compatibility should always be verified against the machine's serial number and existing part references.

1.3 Part Number Reference

| Manufacturer Number | OEM Part Number Reference | Component Description |

|---|---|---|

| HG/DPW Series | LC52D00026F1 | Forged Track Idler Assembly for specified SK330/SK350 configurations. |

| HG/DPW Series | LC52D00002F1 | Forged Track Idler Assembly for specified SK330/SK350 configurations. |

2. Engineering Philosophy: The Forging Advantage for Heavy-Duty Applications

For SK330/SK350 class excavators operating in mining, quarrying, and heavy construction, component failure is not an option. HAN GONG/DPW PARTS employs advanced hot-die forging specifically to meet these extreme demands.

2.1 The Precision Forging Process

Alloy Steel Selection: Utilization of high-grade, heat-treatable alloy steels (e.g., 42CrMo, 50Mn2V) chosen for optimal strength-toughness balance.

Hot-Die Forging: Steel is heated and shaped under extreme tonnage within precision-engineered dies. This process realigns the metal's grain flow to follow the idler's contour, eliminating weak points inherent in castings.

CNC Precision Machining: Post-forging, the component undergoes meticulous CNC turning and boring to achieve OEM-specified tolerances for flange profile, hub dimensions, and sealing surfaces.

Controlled Heat Treatment: A tailored quench and temper cycle creates a graded hardness profile: a supremely wear-resistant outer surface (58-62 HRC) supported by a tough, shock-absorbing core (35-42 HRC).

Sealing & Assembly Integration: The forged wheel is assembled with a heavy-duty, multi-labyrinth sealing system and high-capacity tapered roller bearings, pre-lubricated and tested.

2.2 Key Benefits vs. Conventional Cast Idlers

Unmatched Structural Integrity: Forged microstructure provides 30%+ higher impact and fatigue strength, drastically reducing the risk of catastrophic fracture.

Exceptional Wear Resistance: Denser metal grain translates to prolonged flange and rim life, directly extending undercarriage overhaul intervals.

Superior Performance Under Load: Enhanced ability to handle the dynamic and static loads of 30-50 ton class excavators without deformation.

Optimal Reliability: Predictable, long service life reduces unplanned downtime and associated costs.

3. Technical Specifications & Design Features

3.1 Material Science & Properties

Forging Material: Premium micro-alloyed steel, spectrographically verified.

Mechanical Properties: Ultimate tensile strength > 1200 MPa; Yield strength > 950 MPa.

Hardness Profile: Case-hardened wearing surface for abrasion resistance, with a deep, ductile core for impact absorption.

3.2 Advanced Sealing Technology

Integrated Multi-Barrier Seal: Combines a heavy-duty radial lip seal, a labyrinth dust ring, and an O-ring gasket. This system is designed to exclude fine abrasives (quarry dust, silica) and slurry common in severe environments.

Re-lubrication Design: Features a standard grease fitting, allowing for periodic purging and re-lubrication to extend bearing and seal life.

3.3 Precision Engineering Tolerances

Flange Geometry: Precisely machined to OEM contour to ensure smooth track link engagement and prevent unnecessary wear on track chain components.

Dimensional Stability: All critical interfaces (bore diameter, pilot diameters, bolt hole patterns) are machined to IT7/IT8 grade tolerances for a perfect fit.

4. HAN GONG/DPW PARTS: A Specialist Forging Factory

Our identity as a dedicated forged track guide wheel manufacturer ensures complete control over quality and performance:

Full Process Ownership: In-house capabilities spanning die design & fabrication, forging, heat treatment, machining, and assembly.

Quality Assurance Protocol: Stringent inspection at every stage, including ultrasonic testing for forging integrity, CMM for dimensional accuracy, and torque/rotation testing for assembled units.

R&D Focus: Continuous improvement in metallurgy and seal design to address evolving field challenges.

Global Supply Chain: DPW PARTS network ensures reliable availability and logistical support for customers worldwide.

5. Value Proposition & Total Cost of Ownership (TCO)

Choosing HAN GONG/DPW PARTS forged idlers for your KOBELCO SK330/SK350 represents a strategic investment:

Direct OEM Replacement: Seamless fit and function, guaranteed to match the performance of the original component.

Maximized Uptime: The extended service life of forged components directly increases machine availability for revenue-generating operations.

Reduced Lifetime Cost: While the initial purchase price may be competitive with premium alternatives, the significantly longer wear life results in a demonstrably lower cost-per-operating-hour.

Performance Guarantee: Products are backed by a comprehensive warranty, supported by our technical expertise.