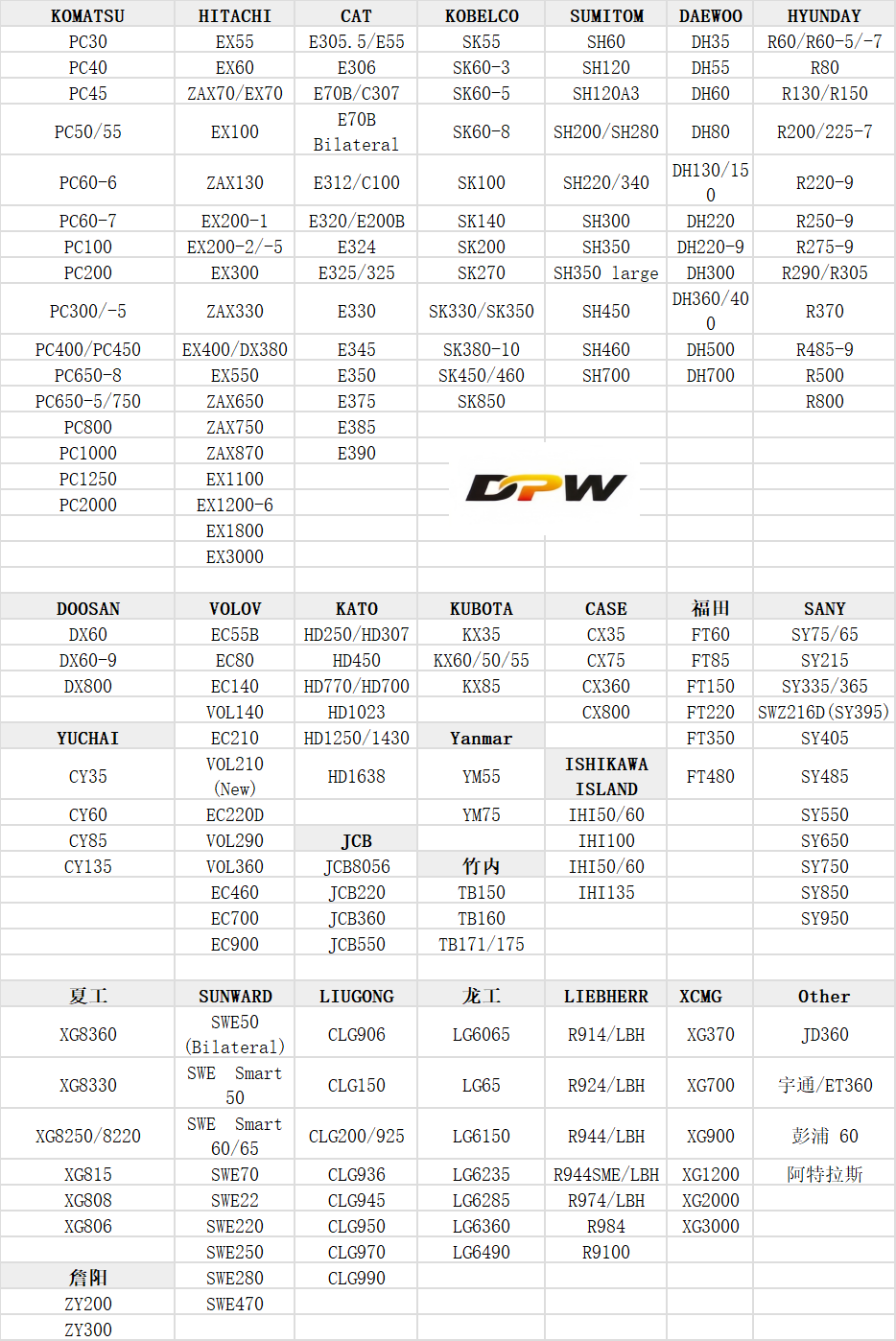

KATO excavator HD1430 HD1250 Forged front idler Wheel 14887/587-50400100/DPW-parts industry/forging idler factory/front idlers wheel manufactures

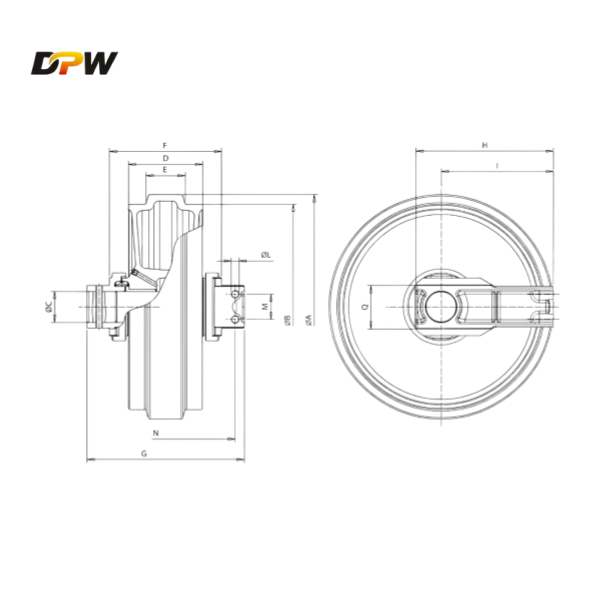

Product Specifications

KATO excavator HD1430/HD1250 forged front idler assembly(14887;587-50400100)DPW-parts industry/forging idler factory/front idlers wheel manufactures/focus on mining machinery

HD1430 Forging Idler – Heavy-Duty Forged Track Roller for Mining & Extreme Applications

HD1430 forging idlers are ultra-robust undercarriage components designed for large mining shovels, 20-30 ton excavators, and extreme-duty crawler equipment. Manufactured through precision hot forging, these idlers deliver maximum durability in the most punishing environments, including iron ore, copper mines, and hard rock quarries.

Core Features & Benefits

✔ Forged Alloy Steel Construction – Superior grain structure for 3X longer life vs. cast idlers

✔ Deep Case Hardening (4-6mm depth) – Rockwell 55-60 HRC surface hardness

✔ Mining-Optimized Design – Extra-wide flanges (20% wider than standard) for track stability

✔ Sealed & Pre-Lubricated – Double-labyrinth seal with high-temp grease for contamination protection

✔ Vibration Dampening – Precision-balanced to reduce undercarriage stress

Technical Specifications

| Parameter | Specification |

|---|---|

| Load Capacity | 18,000 kg dynamic load |

| Bearing Type | XXL tapered roller bearings |

| Flange Type | Double-flange with wear indicators |

| Operating Temp | -40°C to +120°C |

| Weight | 148 kg (standard) |

Heavy-duty Equipment parts

Liebherr R 9100/R 9250 mining excavators

Komatsu PC1600/PC2000 hydraulic shovels

Hitachi EX1800/EX1900 mining excavators

Caterpillar 6015/6020 face shovels

Why Choose Forged Over Cast?

▸ Zero porosity – Eliminates casting defects that cause premature failure

▸ Directional strength – Forging aligns grain flow with stress patterns

▸ Impact resistance – Withstands 50% higher shock loads than cast equivalents

Maintenance & Replacement Indicators

⚠ Replace when:

Flange thickness wears below 65% of original

Visible spalling (>10mm diameter) appears

Bearing free play exceeds 2mm

Grease contamination is detected

🔧 Maintenance Tips:

Pressure-wash weekly to remove abrasive particles

Monitor laser-etched wear markers monthly

Always replace in matched sets (minimum 3 idlers)

DPW-PARTS:thounsands of parts for you to choose from,custmize various chassis parts according to customer needs