JCB220 Final Drive Sprocket Group/JRA0113/Engineering Excellence for Enhanced Undercarriage Performance

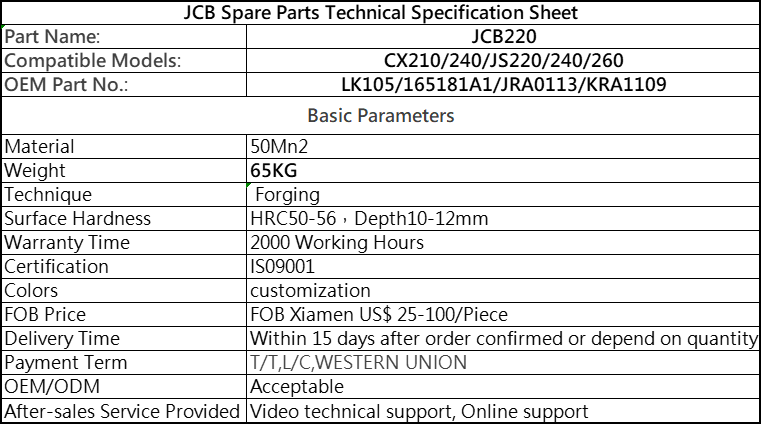

Product Specifications

JCB 220 Final Drive Sprocket Group refers to the assembly responsible for transferring power from the backhoe loader's final drive (gearbox) to the track chain, enabling movement. This is a critical component in the undercarriage system of the JCB 220 excavator.

Here's a breakdown of what this group typically includes and key information:

Final Drive Sprocket (Track Sprocket):

The large, toothed wheel that directly engages with the links of the track chain.

Made from hardened steel to withstand immense wear from the track pins and bushings.

Teeth wear down over time and eventually need replacement. Severe wear leads to poor engagement, track derailment, and damage to the chain.

Final Drive Assembly (Often sold separately but integral to the group function):

A planetary gear reduction unit bolted directly to the track frame or chassis.

Receives high-speed, low-torque input from the hydraulic motor.

Outputs low-speed, high-torque rotation to the sprocket shaft/hub.

Contains gears, bearings, seals, and often the brake assembly.

Sprocket Hub/Shaft:

The shaft or hub that the sprocket mounts onto.

This is the output shaft of the final drive assembly.

Mounting Hardware:

Bolts, nuts, and potentially locking plates to secure the sprocket to the hub/shaft.

Related Components (Often serviced/replaced alongside):

Bearings: Support the sprocket shaft within the final drive housing.

Seals: Critical for keeping lubricant in and dirt/water out of the final drive gearbox.

Track Chain: The sprocket must match the pitch and bushings of the existing track chain. Replacing one often necessitates checking/replacing the other.

Idlers & Rollers: Other undercarriage components that wear together.

Key Points for Identification & Sourcing:

Exact Model & Serial Number is CRITICAL: "JCB 220" is a common model designation, but there are variations (e.g., 220S, different production years). The machine's serial number (S/N) is absolutely essential to get the correct part. JCB parts can vary significantly between serial number ranges.

Sprocket Teeth Count & Pitch: Sprockets are defined by the number of teeth and the chain pitch they are designed for (e.g., 8.50 pitch chain requires an 8.50 pitch sprocket). Using the wrong pitch causes rapid wear and failure.

Left Hand (LH) vs. Right Hand (RH): Final drives and sprockets are specific to the left or right side of the machine.

OEM vs. Aftermarket:

OEM (JCB): Guaranteed fit, quality, and warranty. Usually the most expensive option. Part numbers will be specific (JRA0113 - This is an example only, verify using S/N!).

Aftermarket: Often significantly cheaper. Quality can vary widely from excellent to poor. Reputable brands exist. Ensure compatibility using your machine's S/N and specs (teeth count, pitch, bolt pattern, hub dimensions).

Common Reasons for Replacement:

Worn Sprocket Teeth: The most common reason. Teeth become hooked, pointed, or broken, leading to poor chain engagement, jumping, and derailment.

Damaged Sprocket: Cracks, broken teeth, or severe impact damage.

Final Drive Failure: Internal gear or bearing failure within the final drive unit itself, sometimes requiring replacement of the entire drive assembly (which includes the output shaft/hub the sprocket mounts on).

Seal Failure: Leading to oil leaks and contamination, potentially damaging bearings and gears.

Preventative Maintenance: Replacing high-wear components during major undercarriage overhauls.

How to Proceed:

Locate Your Machine Serial Number (S/N): This is usually on a plate near the cab door, under the bonnet (hood), or on the main chassis frame.

Inspect the Component: Determine exactly what needs replacing:

Is it only the sprocket teeth that are worn?

Are there leaks from the final drive seals?

Is there play or noise in the final drive bearings?

Is the final drive itself damaged or failed?

Source Parts:

JCB Dealer: Provide them with your machine S/N. They will give you the correct OEM part number(s) and price for the sprocket, group, or final drive assembly.

Reputable Aftermarket Suppliers: Provide them with your machine S/N, make, model, and the specific part you need (e.g., "Final Drive Sprocket for LH side"). They should cross-reference to their compatible parts. Ask about warranties and brand reputation.

Online Parts Lookup: Some dealers and major suppliers have online portals where you can enter your S/N to find parts diagrams and numbers.

Important Considerations:

Track Chain Compatibility: If replacing the sprocket, inspect the track chain carefully. A new sprocket paired with a badly worn chain will wear out extremely quickly.

Undercarriage Wear: Final drive/sprocket replacement is often done alongside other undercarriage components (rollers, idlers, chain) if they are significantly worn.

Labour: Replacing a final drive or sprocket is a major job requiring proper lifting equipment, tools, and expertise due to the weight and complexity.

Safety: Always block the machine securely before working underneath it. Follow proper lock-out/tag-out procedures.

|