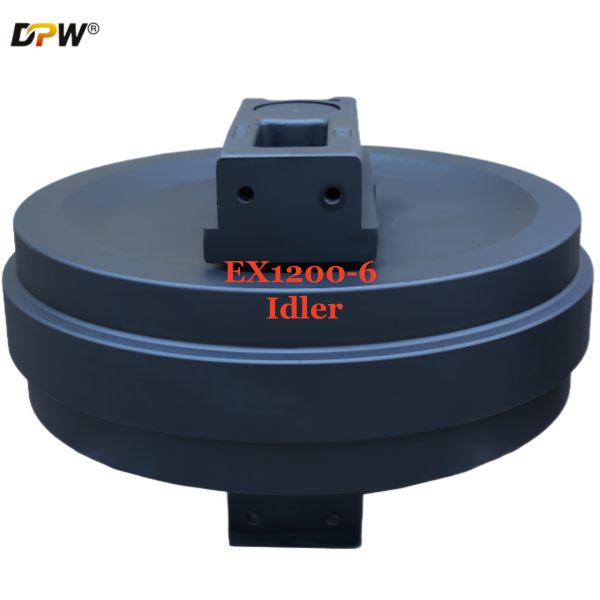

Hitachi YA00035319 YA00035320 EX1200 Guide Wheel/Track Front Idler Assembly/source factory and manufacture

Product Specifications

Technical Description: Hitachi YA00035319 EX1200-6/EX1200-7 Track Front Idler Wheel Assembly

1. General Overview & Functional Definition

The Hitachi YA00035319/YA00035320 Track Front Idler Wheel Assembly is a critical, non-driven component within the heavy-duty undercarriage system of the Hitachi EX1200-6 and EX1200-7 series hydraulic excavators. As a key interface between the track chain and the mainframe, its primary functions are:

Track Chain Guidance and Alignment: It serves as the definitive forward pivot and guide for the track chain, ensuring precise linear travel and proper alignment as the chain enters and exits the undercarriage structure, thereby preventing mis-tracking and lateral drift.

Dynamic Track Tensioning: The entire assembly is mounted on a longitudinally adjustable carriage, actuated by a hydraulic tensioning mechanism. This allows for precise control over track chain sag, which is paramount for optimal power transfer efficiency, mitigating dynamic slippage, and preventing premature wear across the entire undercarriage system.

Initial Load Distribution and Impact Absorption: As the forwardmost ground-engaging component, it bears a significant portion of the machine's dynamic weight and is the primary component for absorbing and dissipating initial shock loads from terrain irregularities, rock impacts, and operational stresses, transmitting these forces into the robust track roller frame.

Articulation Point for Track Links: The idler's precisely machined profile provides a smooth, hardened surface over which the track chain bushings pivot, facilitating the continuous articulation required for the track's endless loop motion while minimizing frictional losses.

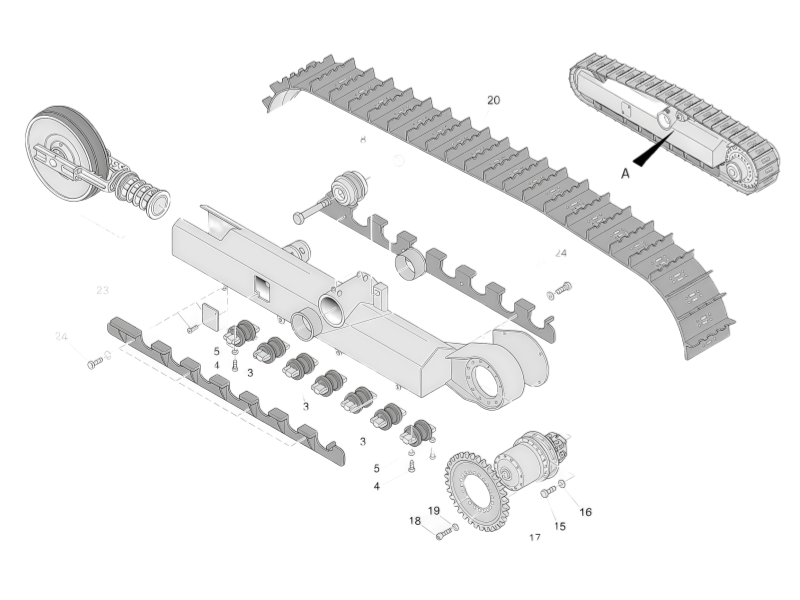

2. Detailed Component Breakdown & Technical Specifications

The assembly, identified by the OEM part number YA00035319, is a fully integrated, pre-assembled unit designed for serviceability and maximum durability in ultra-class mining and quarrying applications.

2.1. Idler Wheel (or Idler Rim)

Material & Manufacturing: Forged from a high-tensile, abrasion-resistant alloy steel such as Cr-Mn-B or Ni-Cr-Mo alloy. The forging process ensures a superior, continuous grain flow that provides exceptional impact toughness and fatigue resistance, far exceeding the capabilities of a cast component.

Design Features:

Robust Dual-Flange Design: The wheel incorporates two massive, integral flanges. These are precision-machined to exact tolerances to provide unwavering lateral guidance for the track chain's links and bushings, critically preventing de-tracking during high-stress turning and side-slope operations.

Advanced Surface Hardening: The running surface that interfaces with the track chain bushings undergoes a submerged arc hard-facing process or deep induction hardening. This results in an extremely thick and durable wear layer (typically 8-12 mm) with a surface hardness exceeding 58-62 HRC, designed to withstand the severe abrasive wear encountered in mining environments.

Precision-Machined Guide Channel: A central groove is machined to perfectly match the height and width of the track chain's guide lugs. This ensures positive centering of the track, distributing loads evenly and enhancing overall stability.

2.2. Idler Shaft (Spindle)

Function: This is the primary structural member, designed to withstand immense bending moments and shear forces. It transmits all operational loads from the idler wheel to the support arms and the main track frame.

Material & Specification: Fabricated from a high-yield-strength alloy steel like 34CrNiMo6 or 4340, followed by a rigorous quenching and tempering heat treatment. This process yields an optimal combination of high core strength and fracture toughness. The shaft journals are precision-ground and often super-finished to a mirror-like surface (e.g., Ra 0.4-0.6) to ensure perfect seal performance and minimize fretting.

2.3. Bearing and Lubrication System

Bearing Type: Given the extreme loads of a 120-ton-class excavator, this assembly utilizes a Double-Row Spherical Roller Bearing or a matched set of Tapered Roller Bearings. These are selected for their ultra-high radial load capacity, inherent self-alignment capability, and robust construction.

Lubrication: The bearing cavity is packed with a high-performance, extreme-pressure (EP) lithium-complex or synthetic grease. The assembly includes a standard grease nipple (zerk fitting) for periodic re-lubrication, which serves to purge ingested contaminants and replenish the lubricant film.

2.4. Multi-Barrier Sealing System

Configuration: A state-of-the-art, multi-stage sealing system is employed, typically combining:

External Labyrinth Seal: A multi-channel, hardened steel labyrinth that acts as the first line of defense, physically excluding large debris and creating a dynamic barrier.

Floating Face Seal: The primary seal, consisting of two precision-ground, spring-loaded sealing rings (often ceramic vs. hardened steel). This provides a highly effective, positive seal against fine abrasives and moisture, even under slight shaft misalignment.

Secondary Lip Seal: An internal rubber lip seal acts as a final barrier to retain grease.

Function: This triple-action system is critical for achieving the extended service life required in high-cost-per-hour mining operations, protecting the bearing from the highly abrasive and contaminant-rich environment.

2.5. Hub & Bracket Assembly

The hub is a heavy-duty, forged or fabricated steel component that forms the core structure, housing the bearings and providing the mounting surface for the idler wheel.

The support brackets are engineered to connect the idler shaft to the track frame's sliding tensioning mechanism, designed with significant structural webbing and gusseting to handle repetitive shock loads.

2.6. Track Tensioning Interface

The assembly features a specifically designed interface, such as a machined socket or a forged yoke, that connects directly to the Hydraulic Track Tensioning Cylinder. This allows for safe and precise adjustment of the idler's position to set and maintain optimal track tension.

3. Integration within the EX1200 Undercarriage System

The Front Idler Wheel Assembly is a system-critical component:

It works in concert with the Final Drive Sprocket at the rear.

It guides the track chain over the Upper Carrier Rollers and Lower Track Rollers.

Its adjustable position directly governs the Track Sag and influences the Ground Contact Length, which are key parameters for machine stability, traction, and overall undercarriage wear rate.

4. Critical Performance & Maintenance Parameters

Wear Limit Adherence: Hitachi provides strict maximum wear limits for the idler wheel's flange height and rim diameter. Operating beyond these limits (e.g., >20mm diameter reduction) drastically increases the risk of de-tracking and causes accelerated, costly wear to the track chain, bushings, and rollers.

Precision Track Tensioning: Adherence to the manufacturer's specified track sag (typically 40-60 mm for a machine of this size) is non-negotiable for maximizing component life and minimizing power loss.

Proactive Seal and Lubrication Maintenance: Regular inspection for seal integrity (looking for grease leakage or contamination ingress) and disciplined re-lubrication according to Hitachi's severe-service intervals are essential for preventing catastrophic bearing failure.

5. Failure Mode and Effects Analysis (FMEA)

Rapid Flange Wear: Typically caused by chronic operation on abrasive side slopes, improperly maintained track tension, or an out-of-alignment undercarriage.

Bearing Seizure: The ultimate result of seal failure, leading to contamination ingress, lubricant degradation, and eventual heat-induced seizure, often causing collateral damage to the hub and shaft.

Idler Rim Cracking or Spalling: Caused by thermal stress from hard-facing, extreme single-impact events, or material fatigue over thousands of operating hours.

Shaft Failure: A rare but catastrophic event usually resulting from an extreme overload scenario, such as a massive side impact, or a progressive fatigue crack originating from a stress riser.

DPW Parts also supply undercarriage parts/Guide wheel YA00035320PS for Hitachi EX1200-7/EX1200-6

- EX1200-6 track shoes assembly 49Links 700MM width shoes track pads YA60049014 9276370 9261703 TRACK ASSEMBLY TRACK 938744/93287/K40252 A0M 49700/UB280K0W49700A

- EX1200-6 track links assy 49Links 9276370 track chains 9328744 VPI VKM2346/49V

- EX1200-6 track pads 700MM track shoes 4669037 BERCO KM2117/700 KOMATSU 21N-32-31110

- EX1200-6 track pads 900MM EX1200-6 track shoes 900MM EX1200 track plates 900MM

- EX1200-6 track bolts BERCO KM2348 KOMATSU 21N-32-31211 VPI V21N-32-31210

- EX1200-6 Track nuts of pads BERCO KM2029 ITM D4047000N17 KOMATSU 198-32-31220 VPI V198-32-31220

- EX1200-6 carrier rollers HITACHI 4638433 EX1200-6 rollers uppers VPI V4638433V Top rollers 4638433

- EX1200-6 sprocket HITACHI 4661591 VPI V4661591V

- EX1200-6 idlers HITACHI 4696615 VPI V4696615V front idlers assy 4666751 YA00035319 YA00035380 GUIDE WHEEL WITHOUT FORK YA00000373/YA00035320/UX133H0E

- EX1200-6 Track rollers bolts J932713

- EX1200-6 TRAVEL DEVICE 9301480

- EX1200-6 ADJUSTER ASS’Y 9271451 TRACK TENSIONER ASSEMBLY China

- EX1200-6 Boom hydraulic cylinder 4665310 (You need to confirm the orientation of your bucket because they use different cylinders.)

- EX1200 ToothV69RC

- EX1200 Tooth pin &retainer

- EX1200 Track rollers bolts J932713

- EX1200 Carrier rollers bolts J932280

- EX1200 sprockets bolts J932785

- EX1200 Track rollers washer 4085857

- EX1200 Carrier rollers washer 4089822

- EX1200 sprockets washer 4085857

- EX1200 YOKE 4670423