Hitachi YA00001980 ZX870/ZX890-5G/ZX900-6A Mining Drive Wheel/Mining Final Drive Sprocket Assy/Heavy duty excavator chassis components expert and manufacturer

Product Specifications

Technical Specification: Mining Drive Sprocket Assembly (Mining Drive Wheel)

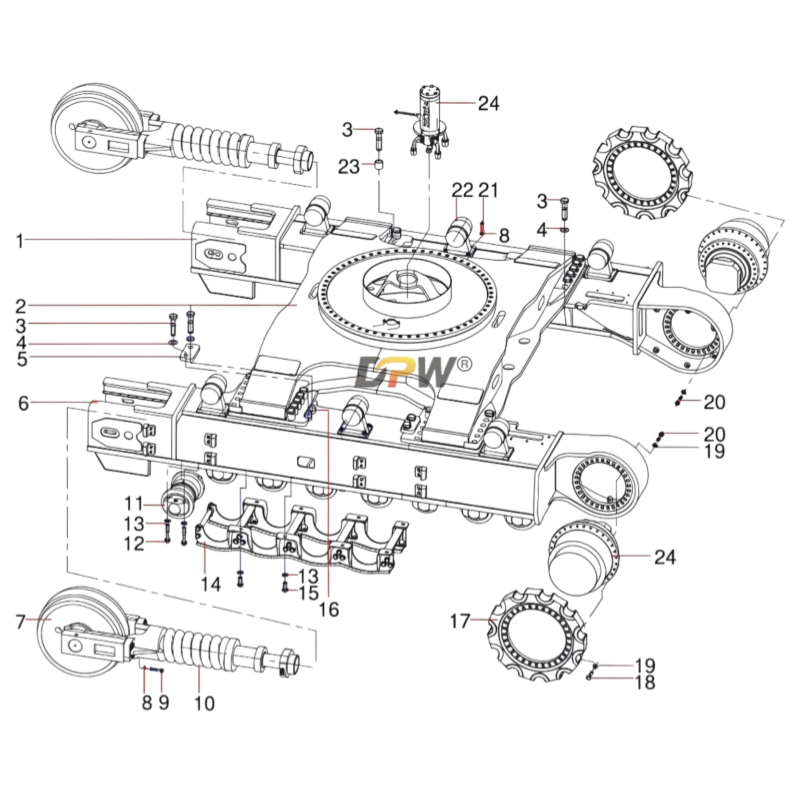

Part Identification:

Compatible Machine Models: Hitachi ZX870, ZX890, ZX900 Mining Excavators.

Application: Final Drive and Track Propulsion System.

Component Type: Mining Duty, Heavy-Pattern Drive Sprocket.

1.0 Component Overview

The Mining Drive Sprocket Assembly for the Hitachi ZX870/ZX890/ZX900 series is a heavy-duty, engineered component designed specifically for the extreme demands of mining and quarrying applications. Unlike standard drive sprockets, this "mining pattern" assembly is built with enhanced mass, superior material specifications, and a robust design to withstand the unparalleled shock loads, continuous high torque, and severe abrasive wear encountered in 24/7 mining operations. It functions as the critical final link, transmitting power from the final drive to the track chain, thereby propelling the massive weight of the mining excavator.

2.0 Primary Function & Operational Context

The core functions of this heavy-pattern assembly are:

High-Torque Power Transmission: To engage with the extra-heavy-duty track chain bushings and transmit the immense rotational force from the large-displacement final drive motors, enabling the machine to move under full load.

Shock Load Absorption: To endure the severe impacts generated when the sprocket teeth engage with the track chain during startup, sudden direction changes, and when operating on uneven, rocky ground.

Extended Service Life in Abrasive Environments: To resist accelerated wear from high-stress grinding against the track chain bushings in the presence of highly abrasive contaminants like silica dust, ore fines, and rock fragments.

3.0 Detailed Construction & Key Sub-Components

This assembly is characterized by its heavy-pattern design, which includes:

3.1 Heavy-Pattern Sprocket Wheel: The most distinguishable feature is its physical size and tooth design.

Increased Mass & Width: The sprocket is wider and has more material around the tooth roots and rim, significantly increasing its structural integrity and heat dissipation capacity.

Reinforced Tooth Design: The teeth are typically taller, thicker, and may have a modified profile to increase the contact area with the track chain bushing. This distributes stress over a larger area, reducing unit pressure and slowing wear.

Material & Hardness: Fabricated from premium alloy steel (e.g., AISI 4340 or equivalent) and subjected to advanced heat treatment like controlled-depth induction hardening. This produces a deep, uniform hardened case on the tooth flanks (typically 58-63 HRC) for maximum wear resistance, while maintaining an exceptionally tough core to prevent crack propagation and tooth breakage.

3.2 Reinforced Hub: The mounting center is designed to handle the higher torque loads, with a robust flange and precise piloting to ensure perfect alignment with the final drive, minimizing stress concentrations on the mounting bolts.

3.3 High-Strength Mounting Hardware: Utilizes specially graded, high-tensile strength bolts and secure locking mechanisms (e.g., Nord-Lock washers, drilled bolts with safety wire) to prevent loosening under vibration and shock loads, which is a critical safety requirement in mining.

4.0 Material & Performance Specifications

Material: Premium Alloy Steel Forging (preferred for superior grain structure and impact strength) or High-Quality Casting.

Heat Treatment: Precise induction hardening to achieve a deep and controlled hardened case depth, often followed by tempering to relieve internal stresses.

Performance Metric: Designed for a significantly longer service life compared to a standard sprocket when operated in a matched undercarriage system under mining conditions.

5.0 Failure Modes & Maintenance Considerations

Wear Progression: While more resistant, the primary wear mechanism remains the gradual material loss from the pressure flank of the teeth, eventually leading to a "hooked" profile. However, the rate of wear is substantially slower than that of a standard-duty sprocket.

Common Failure Modes:

High-Stress Fatigue Fracture: Cracking or tooth breakage due to cyclic loading at or near the material's endurance limit.

Severe Abrasive Wear: While mitigated, extreme environments will still cause measurable wear over time.

Spalling: Surface fatigue on the hardened tooth surface due to repeated high-pressure contact with the track chain bushings.

Maintenance Synergy (System Approach): The performance of a mining-duty sprocket is entirely dependent on the condition of the other undercarriage components. It is absolutely critical to replace it as part of a complete undercarriage set (including the track chain, idler, and rollers). Pairing a new mining sprocket with a worn chain will destroy both components in a very short time. Regular inspection for cracks, abnormal wear patterns, and bolt torque is paramount.