HYUNDAI 81QE11010 R1250 Track Botoom Roller Assembly/Heavy duty crawler excavator Chassis Component supplier DPW PARTS(HAN GONG)

Technical White Paper & Procurement Guide: HYUNDAI 81QE11010 R1250 Heavy-Duty Track Bottom Roller Assembly by DPW PARTS (HAN GONG)

Document ID: WP-CR-2025-001 | Revision: 1.0 | Date: 2025-12-06

Document Navigation

Executive Summary & Product Positioning

Anatomy of the HYUNDAI R1250 Crawler Undercarriage & Roller Function

Deep Dive: Technical Specifications of Part No. 81QE11010

Engineering Excellence & Manufacturing Philosophy of HAN GONG

Failure Mode Analysis & Proactive Maintenance Guidelines

Compatibility, Procurement & Global Supply Chain

1. Executive Summary & Product Positioning

The HYUNDAI 81QE11010 Track Bottom Roller Assembly is a mission-critical component engineered for the demanding operational lifecycle of the R1250-class heavy-duty crawler excavator. As a direct, high-performance replacement for the Original Equipment (OE) part, this assembly from DPW PARTS (HAN GONG) embodies a synthesis of precision manufacturing, advanced material science, and rigorous validation testing. This document serves as a comprehensive technical and commercial guide for procurement officers, maintenance engineers, and equipment fleet managers seeking to optimize undercarriage reliability, total cost of ownership (TCO), and machine availability.

In the ecosystem of heavy machinery, the undercarriage system is a paramount subsystem, accounting for a significant portion of maintenance costs and machine uptime. The bottom roller (or lower roller) operates under extreme cyclic loading, abrasive wear, and environmental contamination. The HAN GONG 81QE11010 is not merely a generic spare part; it is a re-engineered solution that addresses common failure points in OEM designs, offering enhanced durability and performance for severe-duty applications in mining, quarrying, and large-scale earthmoving.

2. Anatomy of the HYUNDAI R1250 Crawler Undercarriage & Roller Function

The crawler undercarriage is the foundation of the excavator's stability, mobility, and weight distribution. For a machine like the R1250, which operates at a working weight exceeding 100 tons, the undercarriage must withstand immense static and dynamic forces.

Core Components & the Roller's Role:

Track Chain & Shoes81QE-26040

: Form the continuous "belt" that contacts the ground.

Sprocket (Drive Wheel)81QE-10010

: Transmits power from the final drive, propelling the track.

Idler (Front Idler)81QE-13010

: Guides the track and, with the tensioning system, maintains proper track sag.

Carrier Rollers (Upper Rollers)81QE-12010

: Support the upper strand of the track.

Track Bottom Rollers (Lower Rollers / Support Rollers): These are the primary load-bearing wheels. They directly support the machine's weight on the track chain and roll along the lower track rail, distributing massive loads to the ground. Their integrity is crucial for maintaining track alignment, reducing rolling resistance, and protecting other undercarriage components from abnormal wear.

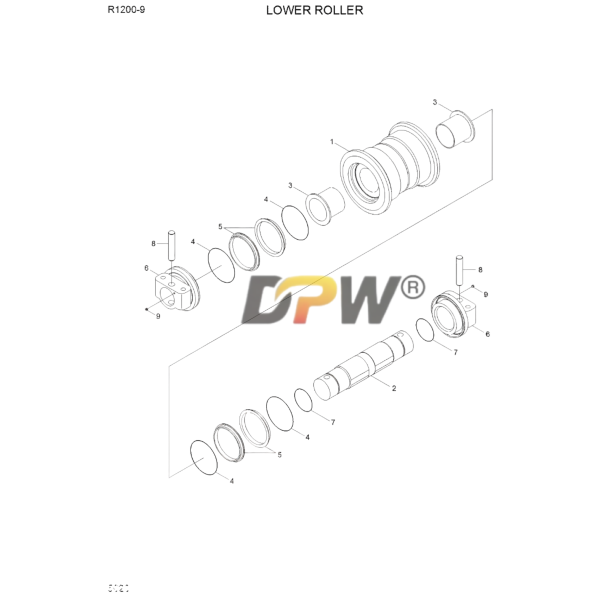

The 81QE11010 Bottom Roller Assembly is a sealed, pre-lubricated unit that bolts directly to the crawler side frame. Its failure directly leads to accelerated wear of the track link, increased fuel consumption, and potential catastrophic damage to the undercarriage frame.

3. Deep Dive: Technical Specifications of Part No. 81QE11010

The HAN GONG assembly is manufactured to exacting dimensional tolerances to ensure seamless interchangeability with the OE part. The following table details its key specifications and the engineering rationale behind them.

| Parameter Category | HAN GONG 81QE11010 Specification | Engineering Significance & Advantage |

|---|---|---|

| OEM Reference | HYUNDAI R1250 (and compatible R-series models) | Guaranteed direct fit, no modification required. |

| Assembly Type | Sealed & Lubricated Track Roller | Pre-filled with high-temperature, extreme-pressure (EP) lithium complex grease for lifelong lubrication, excluding contamination. |

| Flange Design | Singel Flange | Provides superior guidance for the track chain, preventing derailment and lateral slippage under high side loads. |

| Wheel Material & Heat Treatment | Forged 40Mn2Bh 50Mn or 50MnB Alloy Steel; Deep Induction Hardening | Forging ensures a continuous grain flow for high impact strength. Manganese-Boron steel offers excellent hardenability. Deep hardening (case depth >8mm) to 58-62 HRC provides exceptional resistance to abrasive wear, while a tough core (35-40 HRC) prevents brittle fracture. |

| Shaft & Bushing | High-Carbon Chromium Steel Shaft; Sintered Bronze Bushing | Precision-ground shaft for minimal friction. The sintered bronze bushing is oil-impregnated, providing a secondary lubrication source and outstanding wear resistance under high load and low-speed rotation. |

| Sealing System | Multi-Labyrinth with Nitrile Rubber (NBR) Double-Lip Seals | The primary labyrinth seal blocks large contaminants (mud, rocks). The secondary double-lip radial seal, protected by a wear ring, excludes fine abrasive particles (silt, dust) and retains grease. This system is validated for extended service in high-contamination environments. |

| Lubrication | High-Viscosity, Lithium Complex EP Grease | Specially formulated to maintain viscosity and lubricity under high pressure and across a wide temperature range (-30°C to +150°C), reducing internal friction and wear. |

| Quality Assurance | 100% Dimensional Inspection; Sampling for Dynamic Load & Seal Testing | Ensures every unit meets or exceeds OEM geometric and performance standards before shipment. |

4. Engineering Excellence & Manufacturing Philosophy of HAN GONG

DPW PARTS, under the HAN GONG manufacturing division, operates on a philosophy of "Precision Beyond the Blueprint." This involves several core competencies that distinguish it from standard aftermarket suppliers:

Vertical Integration & Process Control: Like leading undercarriage specialists who manage the entire production chain from forging to final assembly, HAN GONG maintains stringent control over critical processes such as metallurgy, heat treatment, and machining. This eliminates quality variance from subcontracted components.

Failure-Driven Redesign: Engineering teams analyze field-returned failed parts to identify root causes (e.g., seal lip wear, spalling, bushing seizure). Lessons are directly incorporated into design iterations, such as optimizing seal geometry or enhancing bushing material porosity.

Advanced Production Assets: Manufacturing leverages state-of-the-art CNC machining centers, automated heat-treatment lines with precise atmosphere control, and robotic welding cells. This ensures batch-to-batch consistency and dimensional perfection.

Validation Testing: Prototypes undergo accelerated life testing on custom rigs that simulate real-world conditions—cyclic radial loading, immersion in abrasive slurry, and high-hour endurance runs—to validate design improvements before mass production.

5. Failure Mode Analysis & Proactive Maintenance Guidelines

Understanding common failure modes is key to proactive maintenance and validates the design choices in the HAN GONG assembly.

Premature Flange Wear: Often caused by misaligned undercarriage or inferior, shallow-hardened material. Solution: HAN GONG's deep-hardened flange resists wear from track chain contact far longer than standard parts.

Seal Failure & Bearing Contamination: The primary cause of roller seizure. Abrasive particles breach the seal, contaminating the grease and acting as grinding paste. Solution: The multi-labyrinth double-lip seal system offers a robust barrier, significantly extending the contamination-free service life.

Spalling or Fracture of the Running Surface: Results from material fatigue or substandard core toughness under heavy impact loads. Solution: The use of forged 50Mn/50MnB steel with a tough, ductile core provides superior resistance to high-cycle fatigue and shock loads.

Maintenance Recommendation: While the assembly is sealed for life, regular visual inspection every 250 operating hours is crucial. Check for:

Fluid Leakage: Grease around the shaft ends indicates seal compromise.

Restricted Rotation: A roller that does not spin freely is likely failing internally.

Abnormal Flange Wear or Damage.

Replace rollers in matched sets on the same side to maintain even track tension and wear.

6. Compatibility, Procurement & Global Supply Chain

Primary Application: HYUNDAI R1250 Crawler Excavator.

Cross-Reference Compatibility: Always consult the latest HAN GONG interchange guide or a certified distributor. This part may be compatible with other HYUNDAI R-series models and certain comparable excavators from other brands using a similar undercarriage design.

Procurement through DPW PARTS: DPW PARTS acts as the global marketing and supply chain arm for HAN GONG manufacturing. They provide:

Certified Quality Documentation: Material certificates, hardness reports, and dimensional inspection records.

Global Logistics: Efficient packaging and shipping via air or sea freight, with full export documentation compliance.

Technical Support: Access to engineering data and installation guidance.

Value Proposition: The HAN GONG 81QE11010 offers an optimal balance between OEM-level performance and aftermarket cost-efficiency. It delivers a lower Total Cost of Ownership (TCO) by extending service intervals, reducing downtime, and protecting adjacent undercarriage components from premature wear.

Disclaimer: Specifications are subject to change due to continuous product improvement. Always verify the exact machine model, serial number, and existing part number before ordering. This document is for technical and informational purposes only.